Precast slab shelf

A technology for placing racks and prefabricated panels, which is applied in the direction of external frames, packaging of vulnerable items, packaging, etc., which can solve the problems of inconvenient transfer process and poor versatility, and achieve the effect of easy transfer and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific implementation examples.

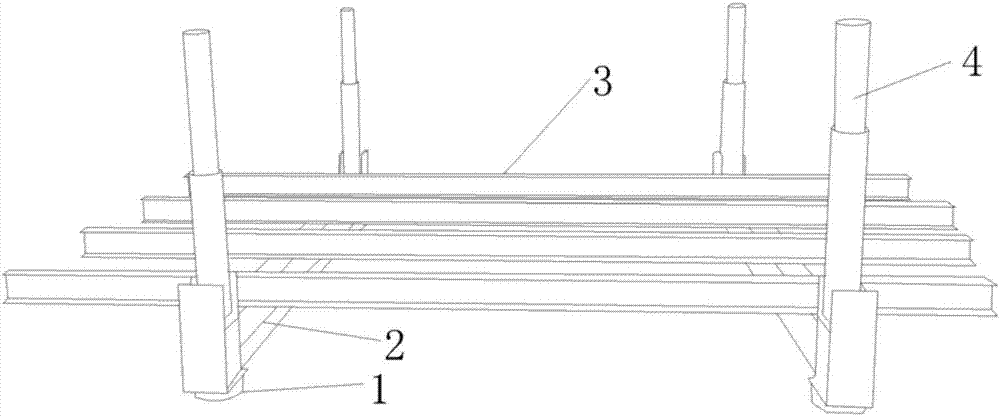

[0012] Such as figure 1 As shown, a prefabricated panel placement frame includes two parallel bottom pillars 2, upright pillars 4 are arranged at both ends of the bottom pillars, and a plurality of parallel load-bearing ribs 3 are arranged on the upper part of the bottom pillars, and the load-bearing ribs are perpendicular to the bottom pillars. The column is a two-stage sleeve structure, the height of the column can be adjusted up and down, the two columns on one side of the shelf are connected to the column base, and the column can be turned down to the ground.

[0013] The two uprights on the other side of the rack are connected to the upright seat through a rotating shaft, and these two uprights can turn inside out to form a cross protection structure. The bottom of the column seat is provided with a pulley 1 and a brake locking mechanism. A guide rail alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com