A crankshaft transfer frame box

A frame box and crankshaft technology, which is applied in the direction of containers, packaging items, special packaging items, etc., can solve the problem of no crankshaft turnover frame box, etc., and achieve the effect of reasonable structure, neat arrangement and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

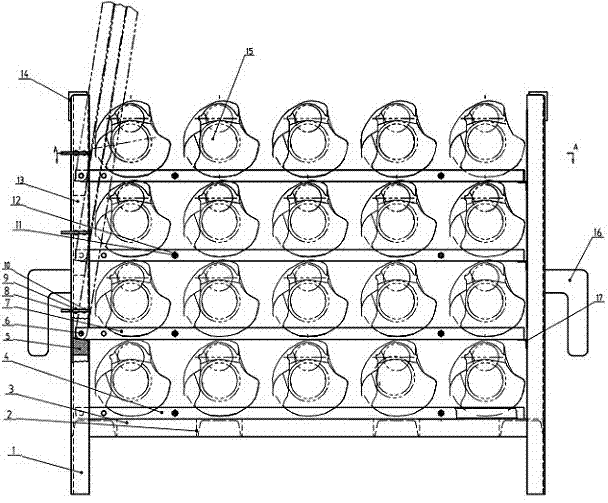

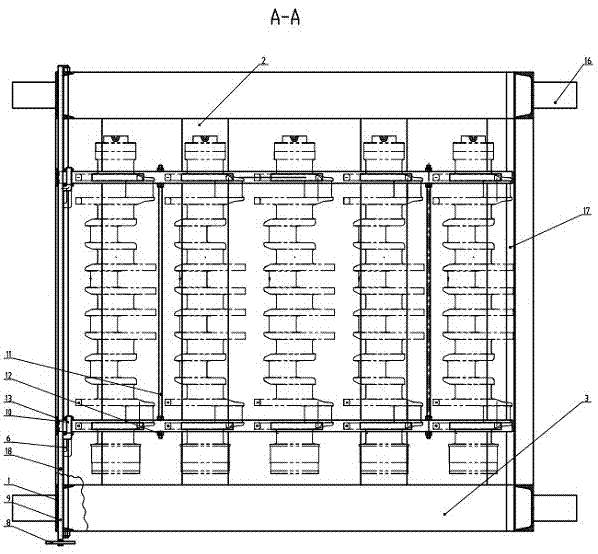

[0016] from figure 1 , figure 2 It can be seen from the figure that a crankshaft turnover frame box includes a base, a pillar 1, a reinforced top plate 14, a trough vertical plate 13, a fixed partition 4, a movable partition 7, a support plate 17, and the like. The base is welded by four horizontal connecting plates 2 and two longitudinal connecting plates 3 . Four columns 1 are vertically welded on the four corners of the base, and two reinforced top plates 14 are arranged on the left and right sides respectively, and the tops of the left and right columns are welded and fixed horizontally. The base, the four pillars and the reinforced top plate form a frame like this. The fixed partition 4 is placed on the transverse connecting plate 2 to form the crankshaft spacer on the first floor at the bottom.

[0017] The present invention is characterized in that: the two trough-type vertical plates 13 are vertically fixed between the left side transverse connecting plate 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com