Automatic needle insertion machine for wooden comb

A needle insertion machine and comb technology, which is applied in wood stamping, wood processing equipment, manufacturing tools, etc., can solve the problems of increasing the frequency of comb teeth replacement, insufficient manual installation, and low work efficiency, so as to reduce the frequency of replacement , Improve assembly efficiency and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

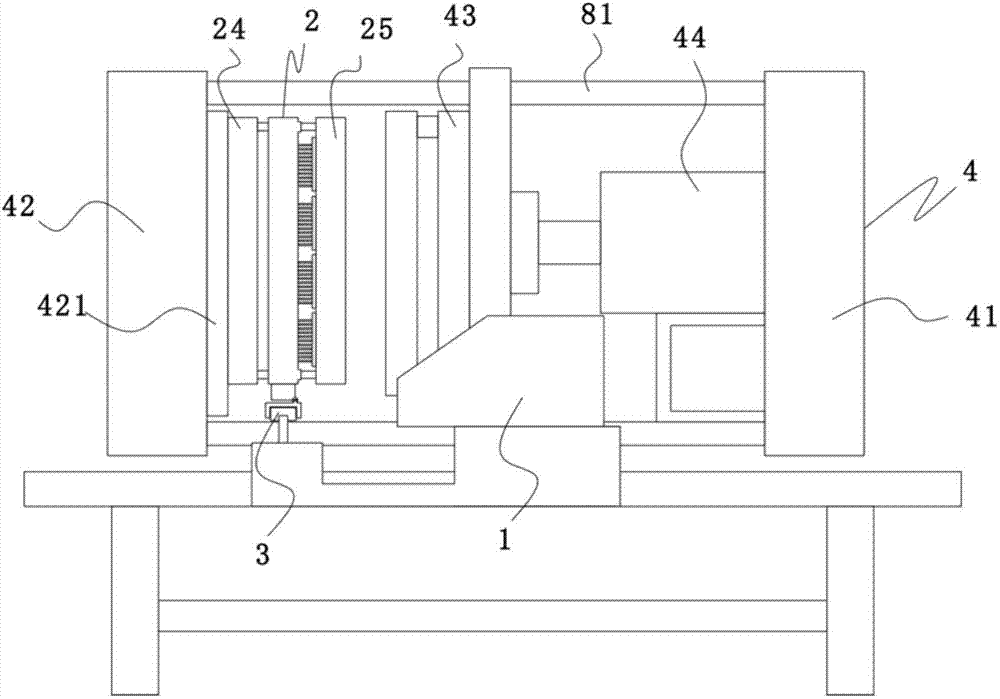

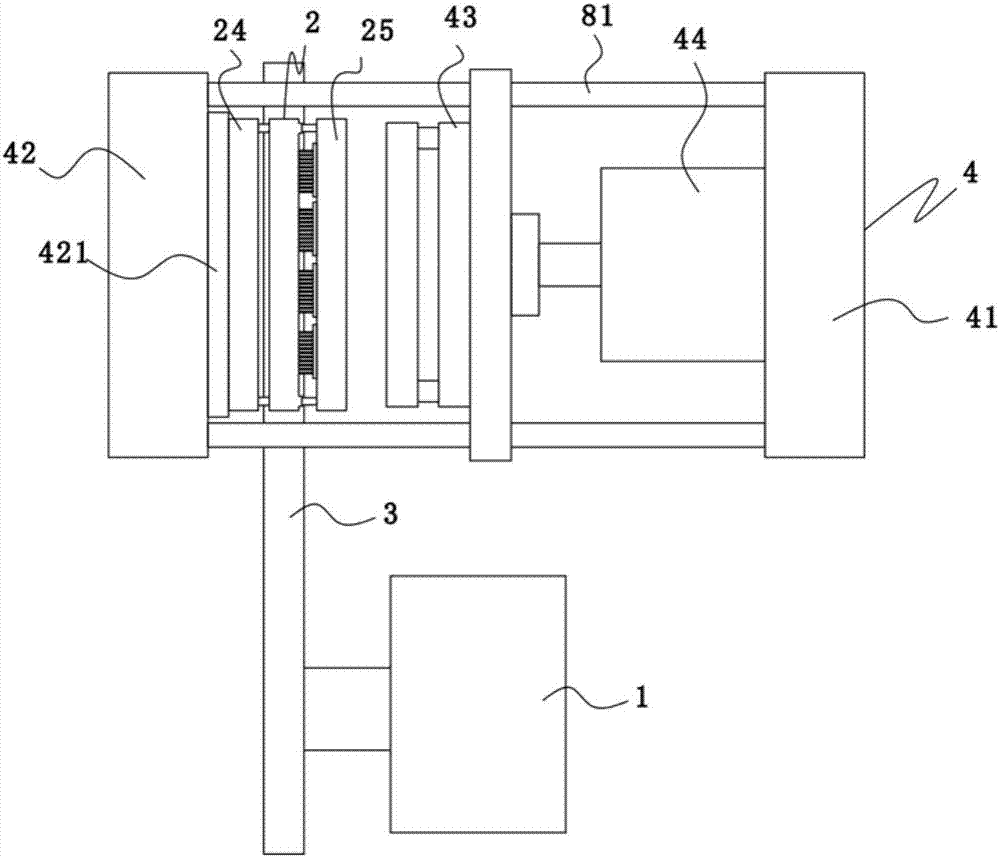

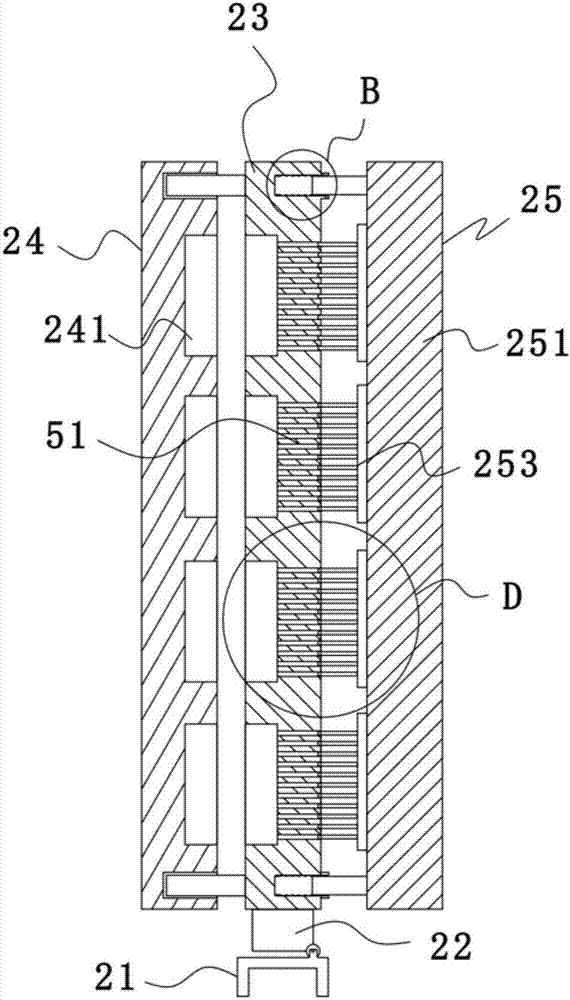

[0021] Such as Figure 1-8 As shown, an automatic needle insertion machine for wooden combs includes a workbench 1, a work position 2, a slide rail 3, and a machine tool 4 for stamping the work position; one end of the slide rail 3 is connected to the machine tool 4. The other end extends to the side of the workbench 1, and the work station 2 can reciprocate on the slide rail 3; specifically, the work station 2 includes a sliding sleeve 21, a connecting part 22, and a positioning plate 23 , finished product collection plate body 24 and stamping part 25, described sliding sleeve 21 is set in U-shaped structure, sleeved on the slide rail, can move back and forth relative to sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com