Method and device for spraying inner wall of mold die cavity of horizontal centrifuge

A technology of horizontal centrifuge and spraying device, which is applied in the direction of tools, manufacturing tools, casting molding equipment, etc. It can solve the problem of affecting the quality of casting high-precision centrifugal tube blanks, uneven coating on the inner wall of mold cavity, and failure to ensure uniformity of spraying and other problems, to achieve the effect that is conducive to spraying quality, avoiding quality problems, and improving spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with embodiment the present invention is described in further detail:

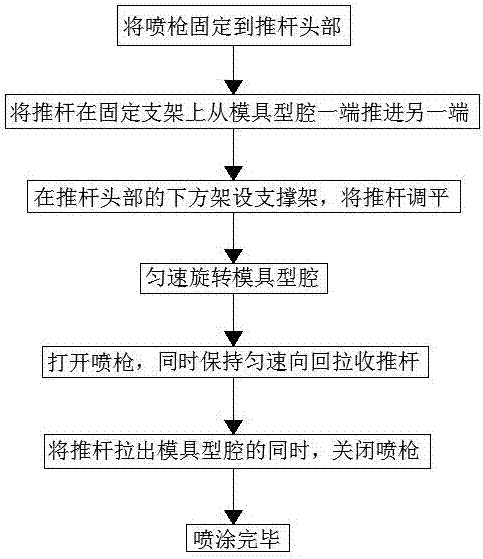

[0034] Such as figure 1 Shown, the mold cavity inner wall spraying method of horizontal centrifuge comprises the following steps:

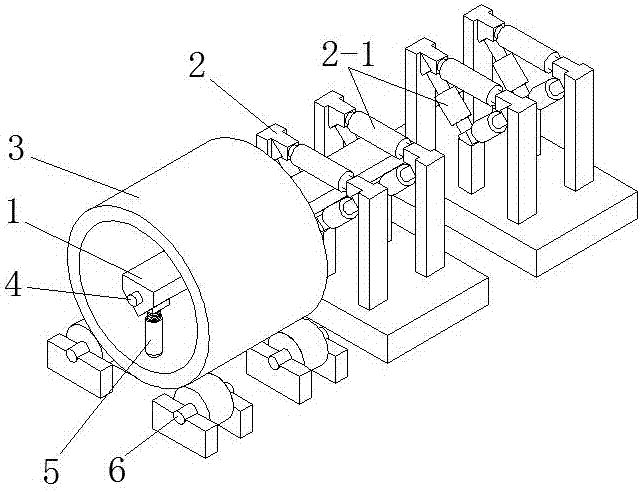

[0035] Step A, fix the spray gun 4 to the head of the push rod 1 .

[0036] Step B. Install the push rod 1 on the fixed bracket 2, keep the center line of the fixed bracket 2 parallel to the center line of the mold cavity 3, push the push rod 1 from one end of the mold cavity 3 into the mold cavity on the fixed bracket 2 3 on the other end of the interior.

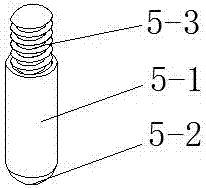

[0037] Step C, erecting a height-adjustable support frame 5 under the head of the push rod 1, the support frame 5 is used to ensure that the push rod will not sag due to gravity;

[0038] Use the support frame 5 to level the push rod 1, so that the shaft of the push rod 1 is parallel to the axis of the mold cavity 3, wherein the support frame 5 can be used to level the push rod 1 by screwing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com