Panel module used for lamp box

A panel module and panel technology, which is applied in the direction of illuminated signs, instruments, display devices, etc., can solve the problems of inconvenient transportation and transportation, no longer suitable, and large distance of opening the front cover, so as to reduce the difficulty of transportation and installation. Reduce the risk of replacement and improve the effect of display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

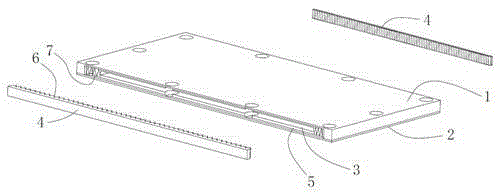

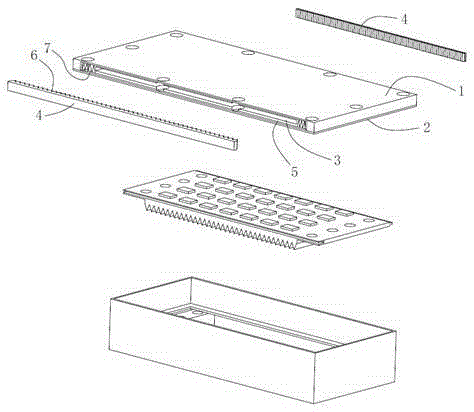

[0036] Example 1: As shown in the figure,

[0037] A panel module for a light box, comprising: a panel 1 and a light guide plate 2, the panel 1 and the light guide plate 2 are a relatively fixed integral structure, and a shelf for placing canvases is arranged between the panel 1 and the light guide plate 2 Through slot 3.

[0038] The panel module used in the light box in this application, because the panel 1 and the light guide plate 2 are set as an integral structure, in the case of ensuring the convenience of transportation, the parts of the light box structure are reduced, which is convenient for transportation and transportation, and reduces the difficulty of transportation. During installation, the panel module and other modules are transported to the site, and then assembled and installed, thereby reducing the difficulty of transportation and installation. When the canvas is replaced later, the lower panel module can be removed and moved to a place that does not hinder ...

Embodiment 2

[0039] Example 2: As shown in the figure,

[0040] In the panel module described in Embodiment 1, the through groove 3 is arranged on the panel 1 or on the light guide plate 2, the through groove 3 is located in the vertical direction of the panel module, the The panel 1 and / or the light guide plate 2 are provided with several pressing pieces 4 for pressing the canvas, the pressing pieces 4 are detachably connected to the panel 1 and / or the light guiding plate 2, the pressing pieces 4 Corresponding to the panel 1 and / or the light guide plate 2, there is a notch 5 matched with the pressing piece 4, when the pressing piece 4 presses the canvas, the outer surface of the pressing piece 4 The end is flush with the panel 1 and / or the light guide plate 2, and the pressing surface of the pressing member 4 to press the canvas is a rough surface provided with knurling, and the panel 1 and / or the light guide plate 2 are aligned with the The surface corresponding to the pressing surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com