Gas mixing device for engine exhaust gas recycling system

A gas mixing device and gas mixing technology, applied in the direction of exhaust gas recirculation, engine components, machines/engines, etc., can solve the problem of insufficient mixing of exhaust gas and air, affecting the stability of the compressor, and the exhaust gas flow of the EGR system cannot meet the needs of the engine, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

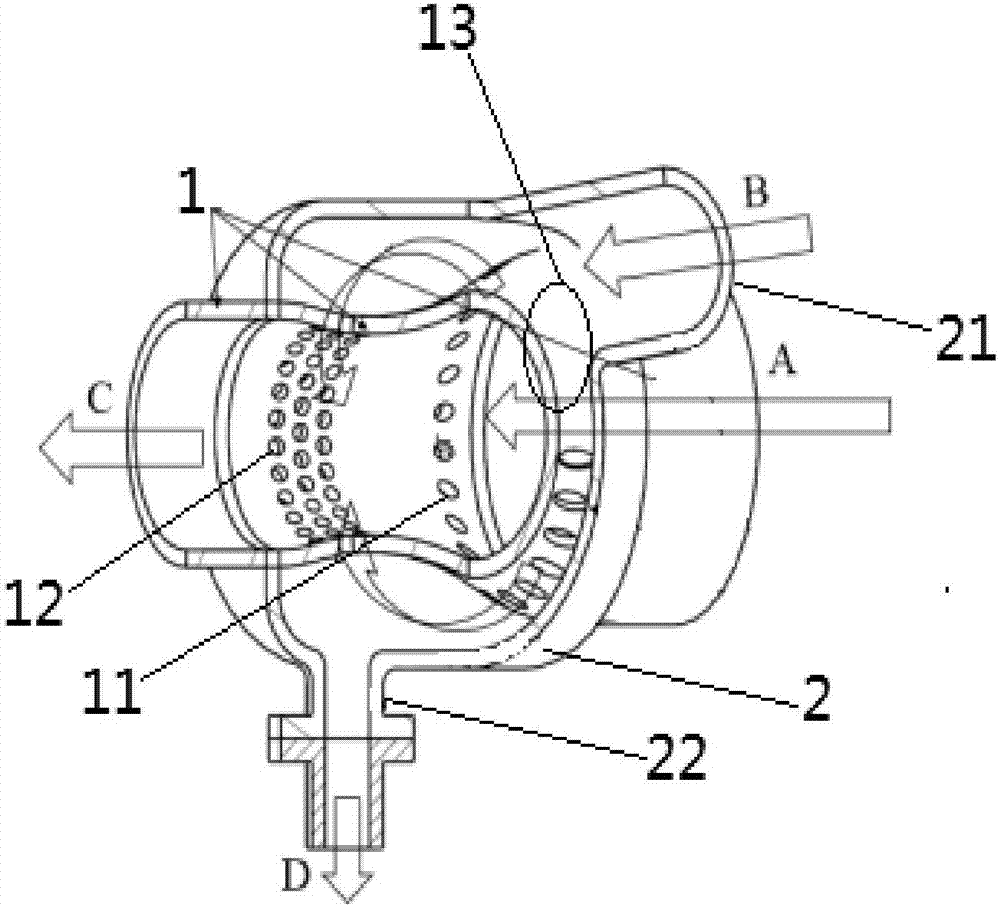

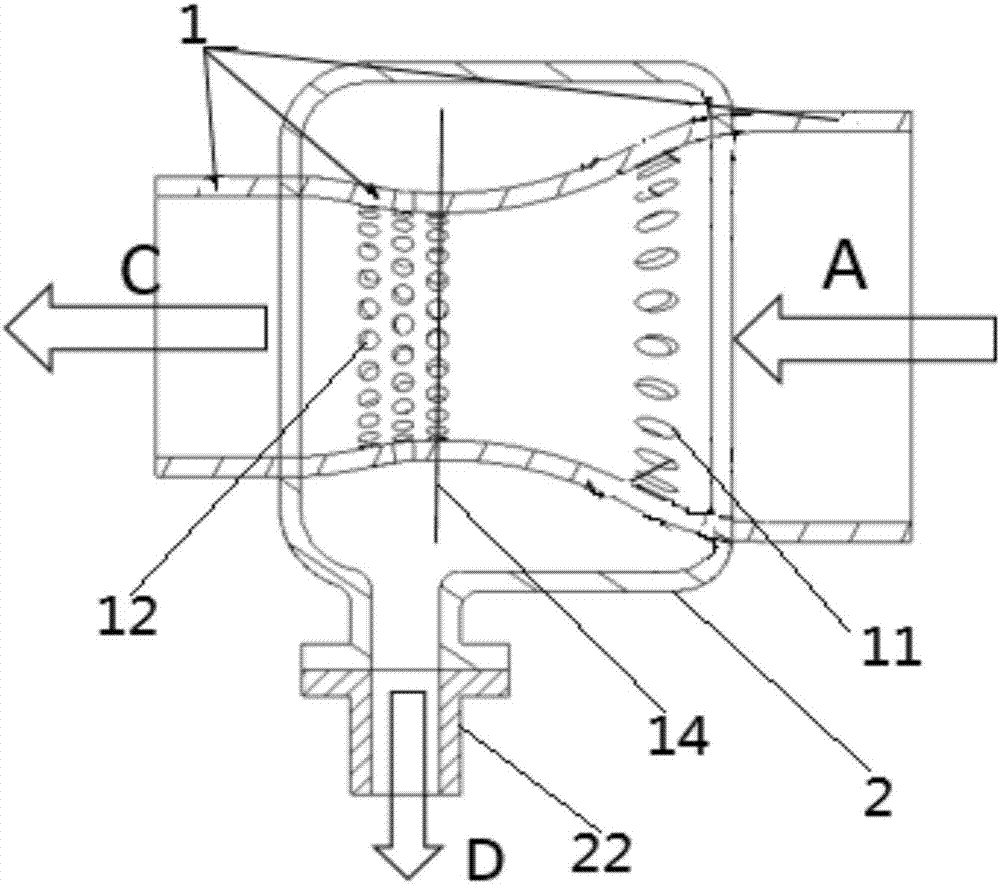

[0033] The task of the EGR system is to make the recirculation of exhaust gas reach the optimum condition at each working point, so that the combustion process is always in the most ideal condition, and finally ensure the lowest pollution components in the emissions. However, on the one hand, after the exhaust gas discharged from the EGR system enters the engine intake system, the condensed water generated by mixing with air impacts the compressor blades of the supercharger, thereby causing the compressor to fail; on the other hand, the gas mixing device of the present technology is only Simply mix exhaust gas with fresh air, that is, discharge the mixed gas when the exhaust gas and fresh air are insufficiently mixed, thus affecting the stability of the engine and compressor work. figure 1 It is a schematic structural diagram of a mixing device used in an engine exhaust gas circulation system according to an embodiment of the present invention, so as to ensure sufficient mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com