A kind of e0 grade melamine modified urea-formaldehyde resin adhesive

A technology of urea-formaldehyde resin glue and melamine, which is applied in the direction of adhesives, adhesive additives, aldehyde/ketone condensation polymer adhesives, etc., which can solve the problems of insufficient board bonding performance, long product production cycle, and high manufacturing costs, etc. problems, to achieve the effect of shortening the hot-pressing cycle, good pre-pressing effect, improving utilization rate and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

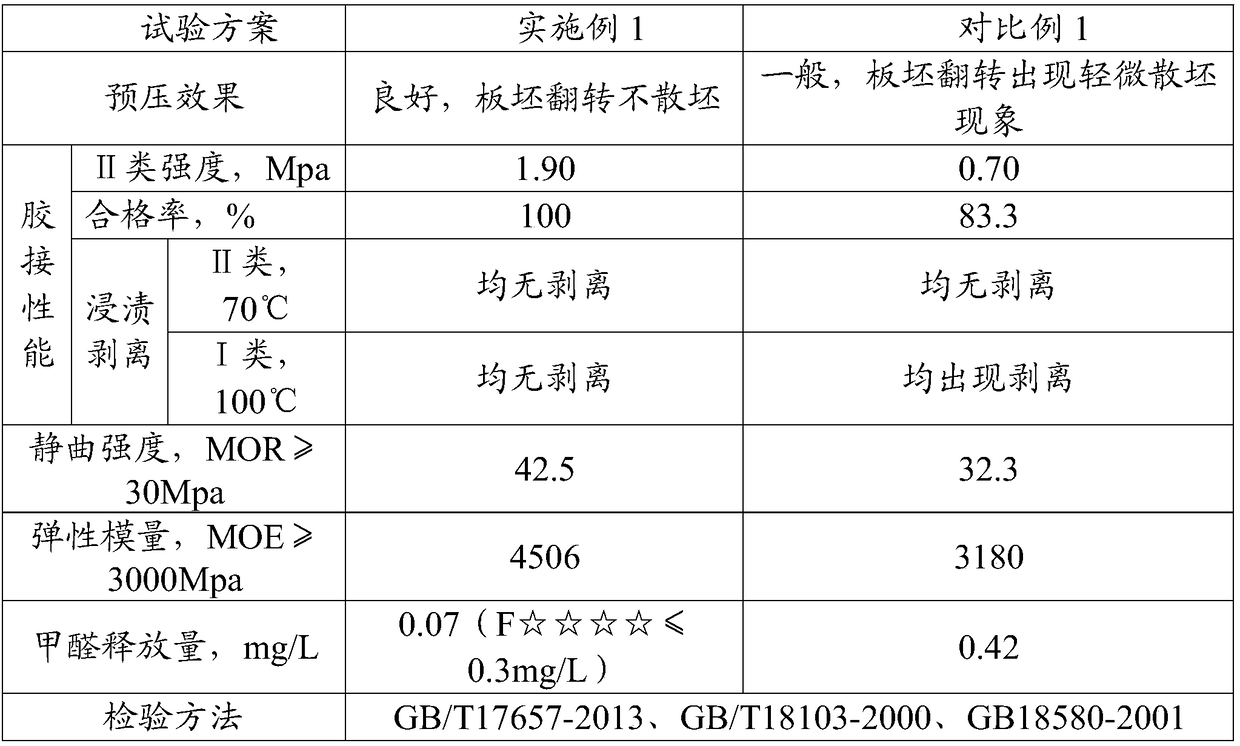

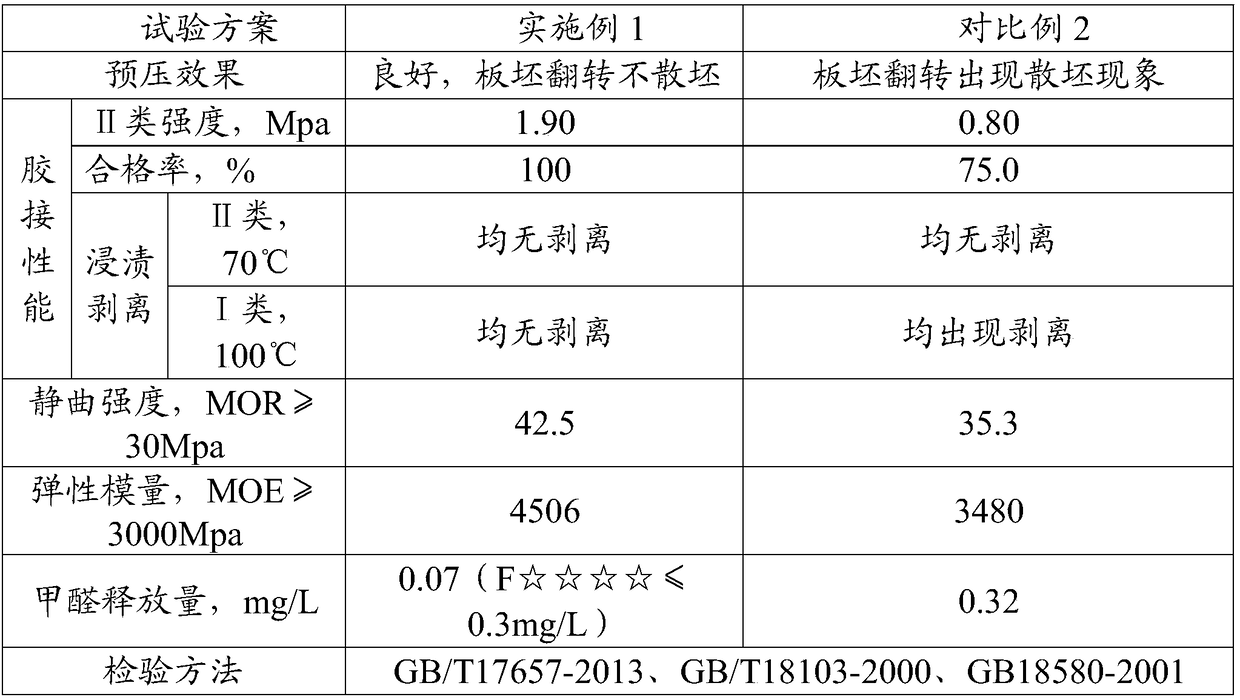

Examples

Embodiment 1

[0032] E of the present invention 0 A kind of embodiment of the preparation method of grade melamine modified urea formaldehyde resin, comprises the following steps:

[0033] (1), adding hexamethylenetetramine, polyvinyl alcohol and water into a formaldehyde solution with a pH of 8.0 to 8.5, and controlling the temperature at 45 to 47°C;

[0034](2) Add the first batch of melamine, control the temperature to 52-54°C, control the pH ≥ 6.5, add the first batch of urea, raise the temperature to 90-94°C, and control the pH to 7.5-7.8;

[0035] (3) Control the temperature to 90-94°C, control the pH ≥ 7.0 until the viscosity is 90-130mPa.s, cool down and quickly add alkali, adjust the pH to 8.5-9.0, add the second batch of melamine, and control the temperature to 85-87 ℃, react until the reaction solution in the kettle turns clear, and check that the pH is 8.0-8.5;

[0036] (4) Add the third batch of melamine, continue the reaction at 82-85°C until the viscosity is 150-180mPa.s, c...

Embodiment 2

[0044] E of the present invention 0 A kind of embodiment of the preparation method of grade melamine modified urea formaldehyde resin, comprises the following steps:

[0045] (1), adding hexamethylenetetramine, polyvinyl alcohol and water into a formaldehyde solution with a pH of 8.0 to 8.5, and controlling the temperature at 45 to 47°C;

[0046] (2) Add the first batch of melamine, control the temperature to 52-54°C, control the pH ≥ 6.5, add the first batch of urea, raise the temperature to 90-94°C, and control the pH to 7.5-7.8;

[0047] (3) Control the temperature to 90-94°C, control the pH ≥ 7.0 until the viscosity is 90-130mPa.s, cool down and quickly add alkali, adjust the pH to 8.5-9.0, add the second batch of melamine, and control the temperature to 85-87 ℃, react until the reaction solution in the kettle turns clear, and check that the pH is 8.0-8.5;

[0048] (4) Add the third batch of melamine, continue the reaction at 82-85°C until the viscosity is 150-180mPa.s, ...

Embodiment 3

[0056] E of the present invention 0 A kind of embodiment of the preparation method of grade melamine modified urea formaldehyde resin, comprises the following steps:

[0057] (1), adding hexamethylenetetramine, polyvinyl alcohol and water into a formaldehyde solution with a pH of 8.0 to 8.5, and controlling the temperature at 45 to 47°C;

[0058] (2) Add the first batch of melamine, control the temperature to 52-54°C, control the pH ≥ 6.5, add the first batch of urea, raise the temperature to 90-94°C, and control the pH to 7.5-7.8;

[0059] (3) Control the temperature to 90-94°C, control the pH ≥ 7.0 until the viscosity is 90-130mPa.s, cool down and quickly add alkali, adjust the pH to 8.5-9.0, add the second batch of melamine, and control the temperature to 85-87 ℃, react until the reaction solution in the kettle turns clear, and check that the pH is 8.0-8.5;

[0060] (4) Add the third batch of melamine, continue the reaction at 82-85°C until the viscosity is 150-180mPa.s, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com