Four-claw type humanoid pipe climbing robot

A technology for robots and pipe-climbing, applied in the field of pipe-climbing robots, can solve the problems of unstable operation, poor carrying capacity, and inability to cross pipes, etc., and achieve the effects of good work stability, strong load capacity, and high moving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, which is not intended to limit its protection scope.

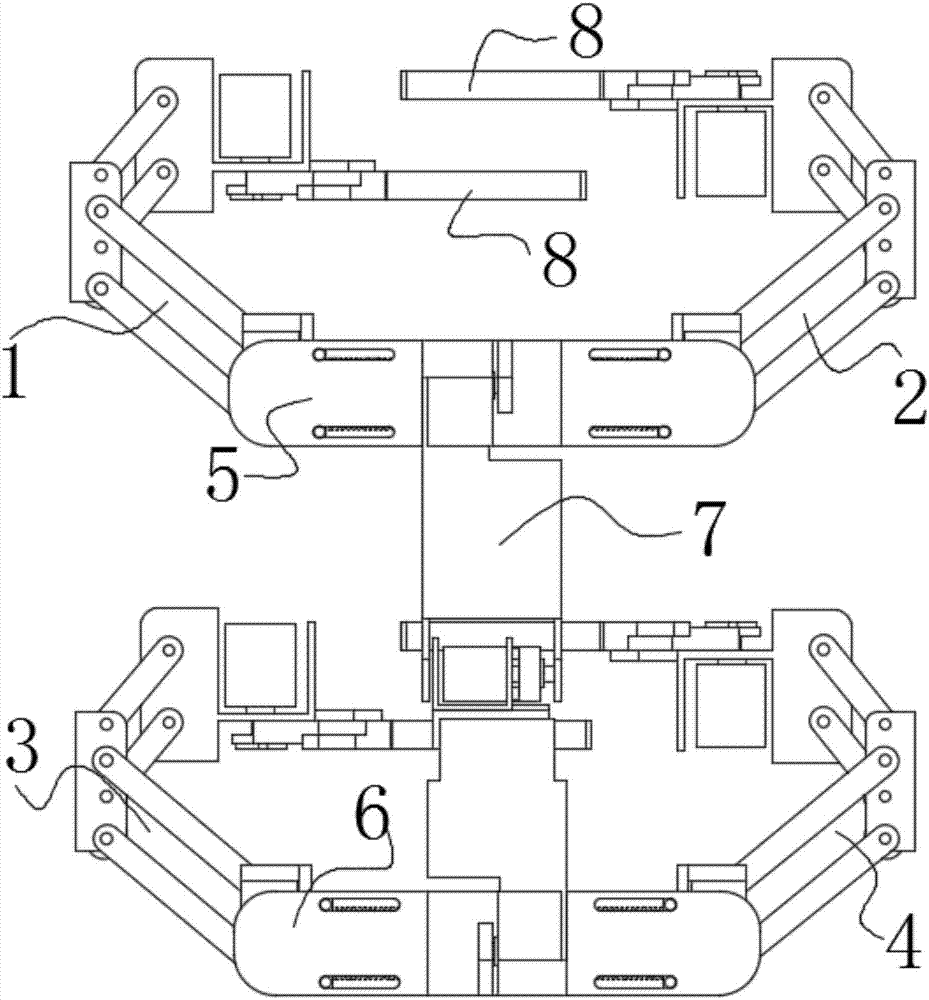

[0033] likefigure 1 and figure 2 As shown, a four-claw humanoid pipe-climbing robot includes symmetrically arranged limbs and an upper torso 5 and a lower torso 6 that connect the limbs as one; Robotic arm, the limbs are left upper limb 1, right upper limb 2, left lower limb 3 and right lower limb 4, wherein left upper limb 1 and right upper limb 2 are respectively connected to the left and right ends of the upper torso 5, left lower limb 3 and right lower limb 4 are respectively connected to The left and right ends of the lower torso 6 are connected;

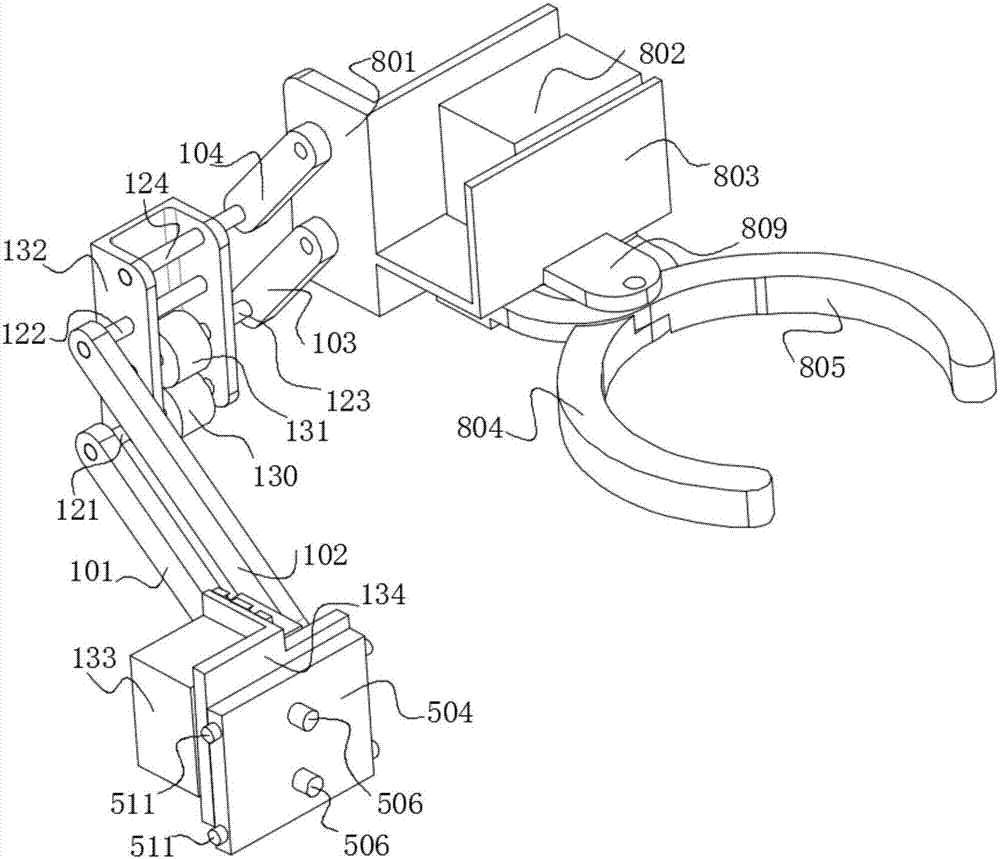

[0034] like Figure 5 and Figure 6 As shown, the upper torso 5 includes a trunk bottom plate 501, two extruded sliding blocks 504 and four support plates 502 respectively arranged at two ends of the trunk bottom plate 501, and the two sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com