Dual-mode hybrid power transmission device of front-wheel drive car

A transmission and hybrid technology, applied in the direction of power plant, electric power plant, pneumatic power plant, etc., can solve problems such as affecting transmission efficiency, and achieve the effect of wide transmission ratio range, reduction of energy conversion process, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

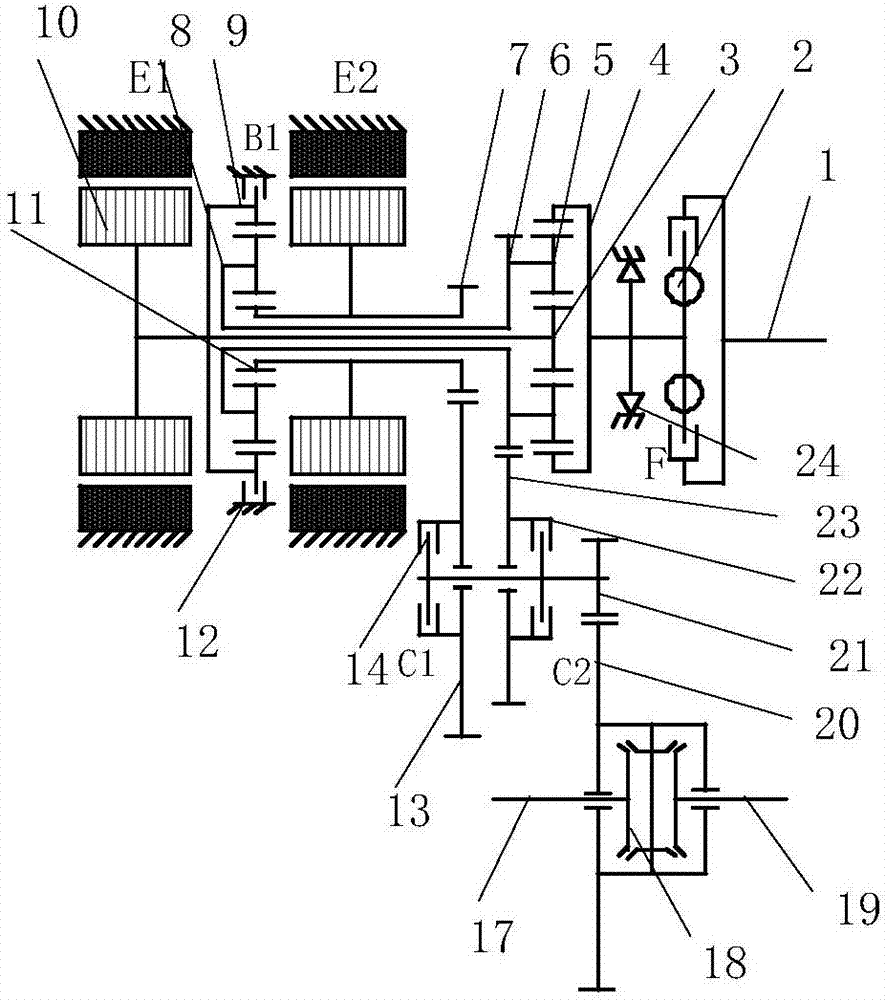

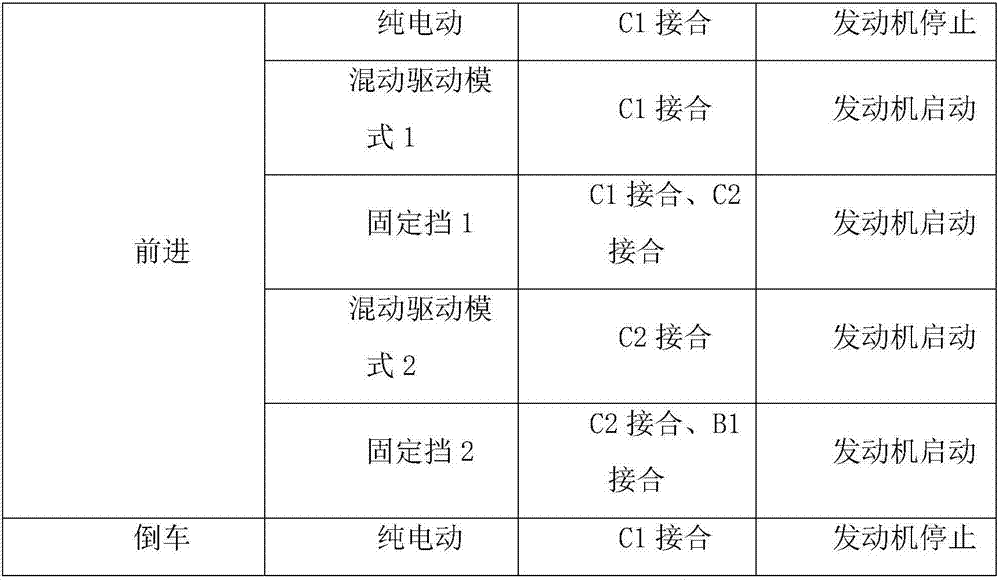

[0023] Embodiment 1: see attached figure 1 , a dual-mode hybrid transmission for a front-drive vehicle, which includes: an engine input shaft 1, a torsional shock absorber 2, a double planetary mechanism, a first gear 6, a second gear 7, a first motor E1, a first brake 12, Third gear 13, first clutch 14, second motor E2, first output shaft 17, differential 18, second output shaft 19, fifth gear 20, sixth gear 21, second clutch 22, seventh gear 23, one-way clutch 24;

[0024] The first motor E1 and the second motor E2 are coaxially arranged, that is, the output shaft of the second motor E2 is coaxially sleeved outside the output shaft of the first motor E1, and the stators of the two motors are fixedly connected to the transmission housing;

[0025] The double planetary mechanism includes: the first planet carrier 5 and the second planet carrier 8 connected to each other, the first sun gear 3 installed on the first planet carrier 5, the first ring gear 4 and the The second ri...

Embodiment 2

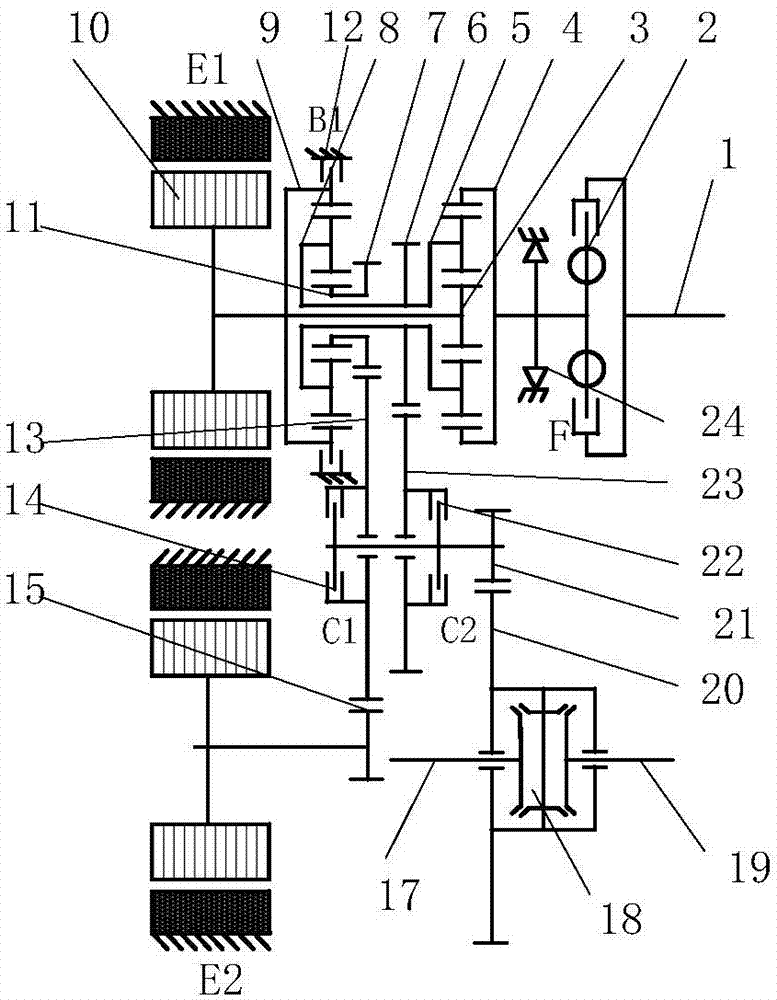

[0040] Embodiment 2: see attached figure 2 , a dual-mode hybrid transmission for a front-drive vehicle, which includes: an engine input shaft 1, a torsional shock absorber 2, a double planetary mechanism, a first gear 6, a second gear 7, a first motor E1, a first brake 12, Third gear 13, first clutch 14, fourth gear 15, second motor E2, first output shaft 17, differential 18, second output shaft 19, fifth gear 20, sixth gear 21, second clutch 22, the seventh gear 23, the one-way clutch 24;

[0041] The first motor E1 and the second motor E2 are arranged on different axes; the stators of the two motors are fixedly connected to the transmission housing;

[0042] The double planetary mechanism includes: the first planet carrier 5 and the second planet carrier 8 connected to each other, the first sun gear 3 installed on the first planet carrier 5, the first ring gear 4 and the The second ring gear 9, the second sun gear 11; the first sun gear 3 is connected to the second ring g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com