Multi-wavelength laser welding method and multi-wavelength laser device for multilayer plastic

A laser device and laser welding technology, applied in optics, optical components, instruments, etc., can solve the problems of limiting the types of plastic materials, difficulty in improving welding effect, and difficulty in speed, so as to achieve the effect of diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

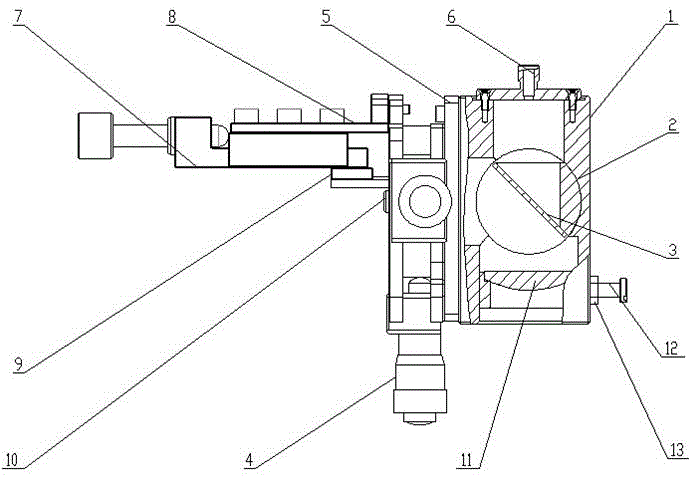

Image

Examples

Embodiment

[0056] At present, there are many kinds of plastic welding materials. The materials and optical properties of the upper welding material and the lower welding material are not disclosed. The wavelength should be selected according to the welding material, rather than fixed. The case description is therefore realized using symbols.

[0057] The plastic materials to be welded are A and B respectively, wherein the A material is above the B material, and the two are in contact. Material A has strong absorption for laser with a wavelength of Xnm, and material B has strong absorption for laser with a wavelength of Ynm, while material A has weak absorption for laser with a wavelength of Ynm, and material B has weak absorption for laser with a wavelength of Xnm. Lasers with wavelengths of Xnm and Ynm are selected as the laser light source, where the absolute value of X is greater than Y. Here, the laser with the wavelength of Xnm is called the X laser, and the laser with the wavelengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com