Cutting machine tool horizontally cutting sand line

A sand wire cutting machine tool and horizontal cutting technology, which is applied in the direction of grinding machines, fine working devices, working accessories, etc., can solve the problems of low production efficiency, time-consuming and troublesome installation, etc., and achieve the goal of improving efficiency, improving cutting accuracy and extending service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

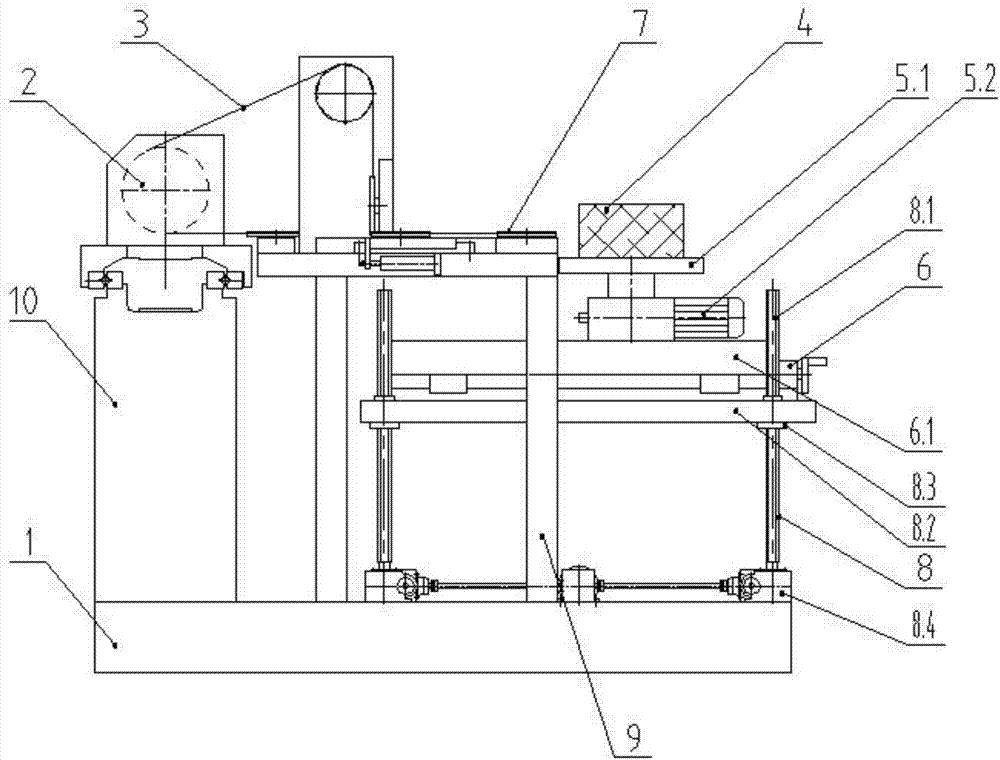

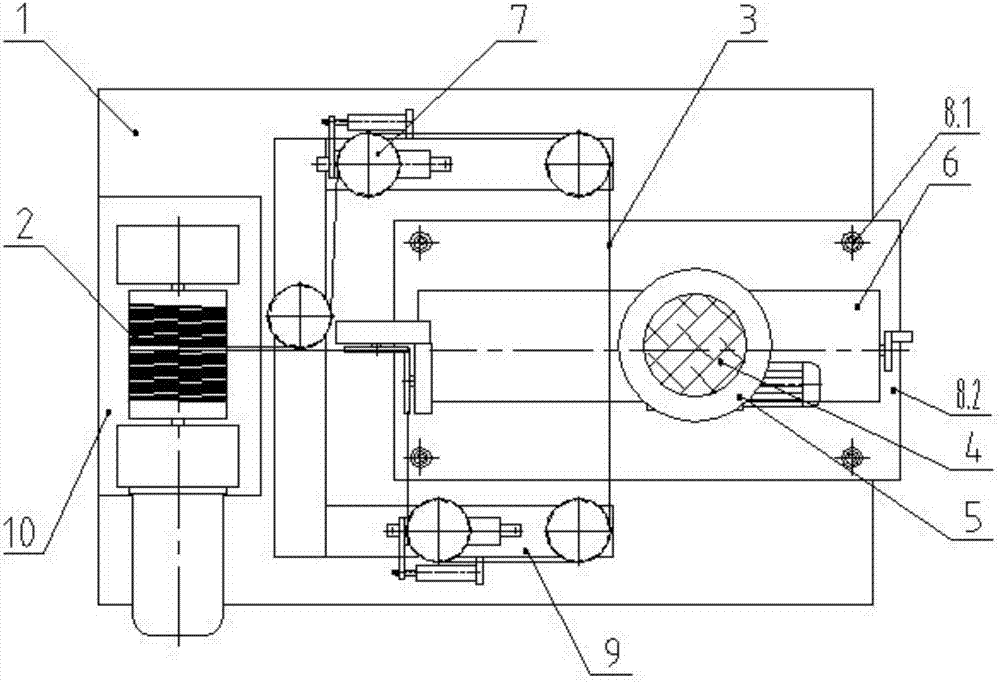

[0029] The horizontal cutting sand wire cutting machine shown in the accompanying drawings includes a base 1, a wire storage barrel 2, a wire storage barrel moving part 10, a sand line 3, a turntable assembly 5, a workbench assembly 6, a guide wheel assembly 7, a lifting mechanism 8, a guide Wheel support frame 9.

[0030] The central axis of the wire storage drum 2 is placed flat, and is arranged on the wire storage drum moving part 10, and is driven by the wire storage drum moving part 10 to realize horizontal movement left and right; the wire storage drum 2 includes a cylindrical cylinder body 2.1, and the wire storage drum 2 cylinder body 2.1 Nylon layer 2.1.1 is provided on the outer surface (in other embodiments, resin layer 2.1.1 is provided on the outer surface of the cylinder body 2.1 of the wire storage barrel 2); the nylon la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com