Angle steel pre-straightening device

A pre-straightening and angle steel technology, which is applied in metal rolling, manufacturing tools, metal processing equipment, etc., can solve the problems of high labor intensity of workers, angle steel top shearing edge, unfavorable angle steel shearing and production, etc., to reduce employee labor Intensity, the effect of reducing the number of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

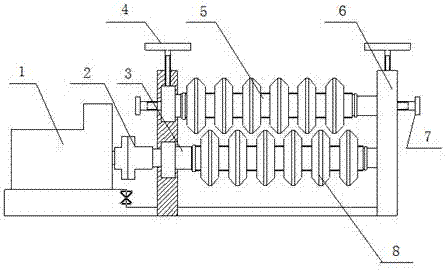

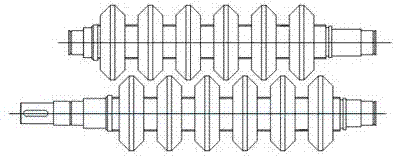

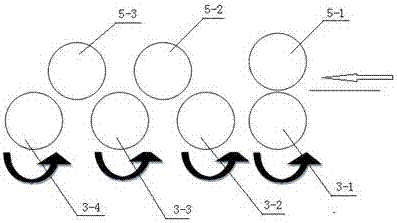

[0014] Refer to attached figure 1 , 2 , 3, an angle steel pre-straightening device, comprising a power assembly 1, a coupling 2, a lower straightening roller group 3, a pressing adjustment mechanism 4, an upper straightening roller group 5, a roller frame 6 and a horizontal adjustment mechanism 7 , the upper straightening roller group 5 and the lower straightening roller group 3 are arranged in the roll frame 6, the upper straightening roller group 5 and the lower straightening roller group 3 are arranged in parallel up and down, and the lower straightening roller group 3 is connected with the The power assembly 1 is driven and connected, and the upper straightening roller group 5 is provided with a pressing adjustment mechanism 4 and a horizontal adjustment mechanism 7. The upper straightening roller group 5 includes an upper straightening roller 5-1, an uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com