Discharge circuit and discharge control method

A technology of discharge control and discharge resistance, which is applied in the direction of battery circuit devices, circuits, circuit devices, etc., can solve the problems of inability to realize active discharge at the output end, increase the complexity of module design, and affect system functions, so as to avoid heat accumulation and reduce Device cost, effects of extended application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

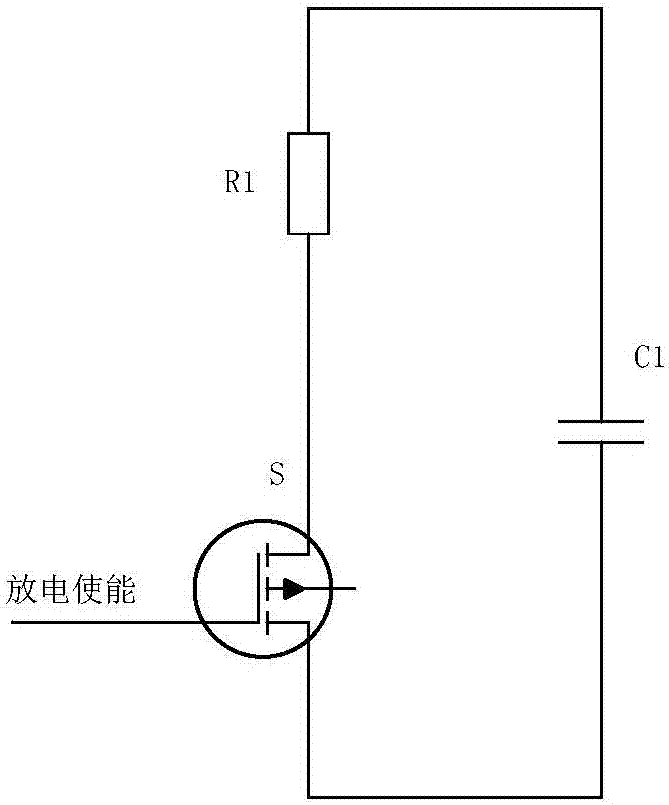

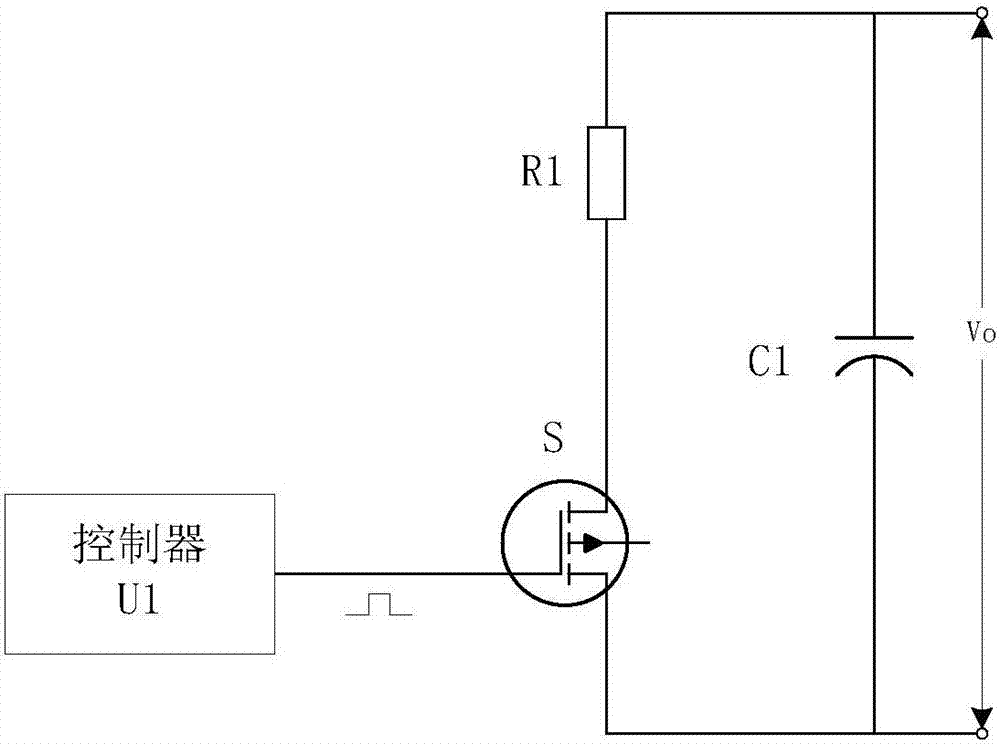

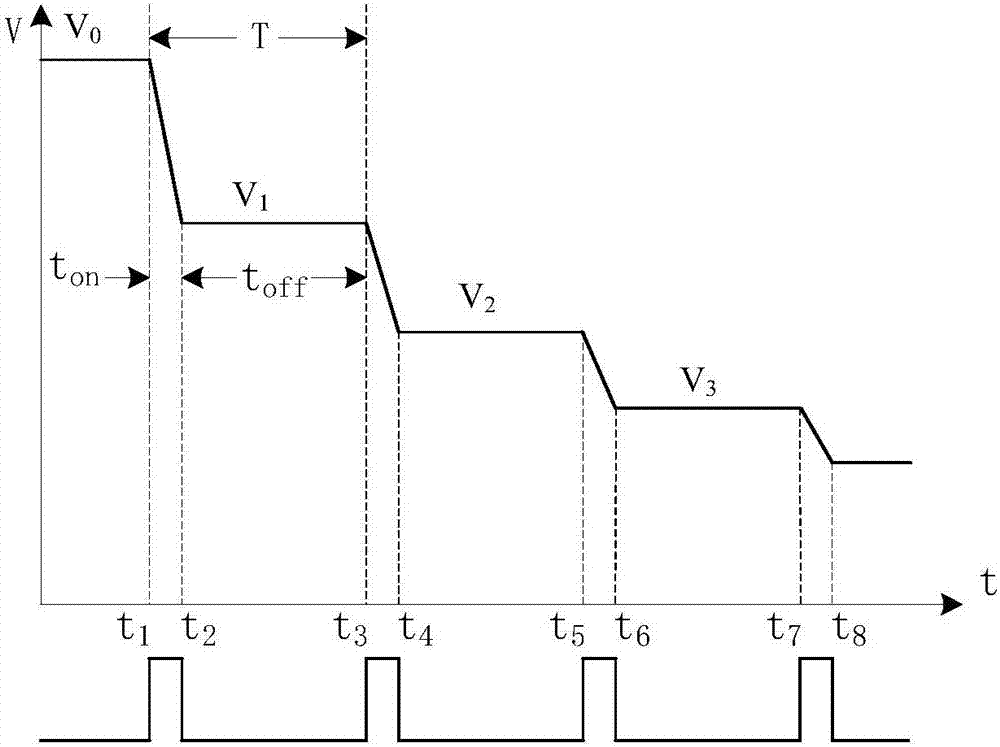

[0070] figure 2 It is a circuit diagram of Embodiment 1 of the output port filter capacitor and discharge circuit of the present invention. The DC charging module of this embodiment includes a voltage conversion circuit (not shown), a filter capacitor C1 and a discharge circuit, wherein the voltage conversion circuit is used to convert the AC market The electricity is converted into direct current and provides power for electric vehicles. The filter capacitor C1 is set at the output port of the DC charging module, and is used to reduce the ripple of the output voltage. The discharge circuit includes a discharge resistor R1, a switch tube S and a controller U1. Among them, the discharge resistor R1 preferably has a power resistor with a certain impact resistance, and the first end of the discharge resistor R1 is connected to the first end of the filter capacitor C1, and the second end of the discharge resistor R1 is connected to the first end of the switch tube S , the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com