A shunting device for manipulator live work

A technology of live work and shunt device, applied in cable installation device, switch device, cable installation and other directions, can solve the problems of high psychological pressure of maintenance personnel, difficulty in meeting supply and demand, long power outage time, etc., to ensure continuous power supply, The effect of shortening the repair time and avoiding hidden safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

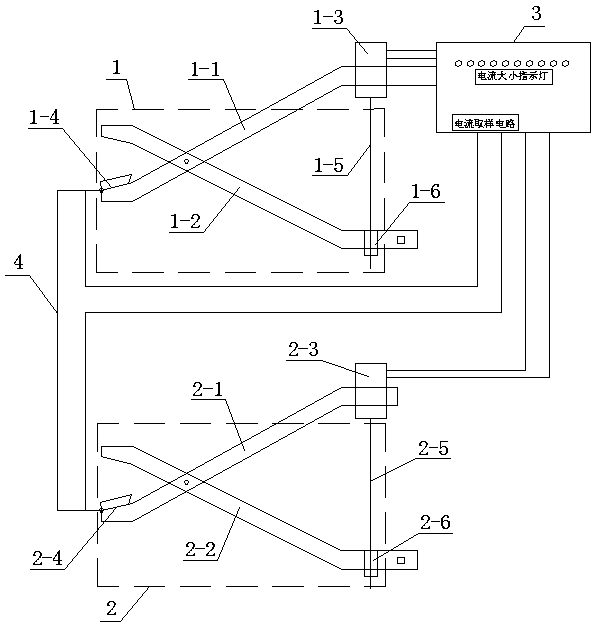

[0020] Below in conjunction with the accompanying drawings, the implementation of the manipulator live work diversion device will be further described in detail:

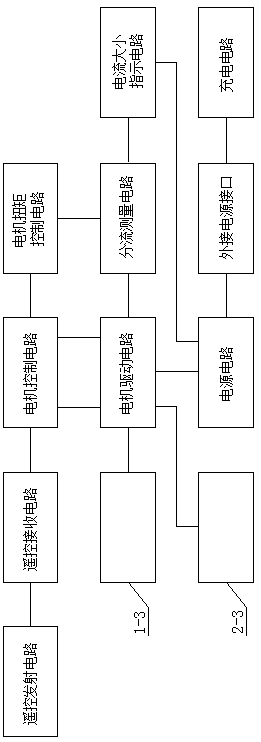

[0021] The shunt device for manipulator live work is composed of manipulator A1, manipulator B2, control system 3, and shunt line 4. Manipulator A1 and manipulator B2 are equal in size, structure and shape; manipulator A1 is composed of movable arm A1-1 and fixed arm A1-2. , gear motor A1-3, jaw A1-4, screw rod A1-5, nut A1-6; manipulator B2 consists of movable arm B2-1, fixed arm B2-2, gear motor B2-3, jaw B2- 4. The screw rod B2-5 and the nut B2-6 are composed; the control system 3 is composed of a remote control transmitter circuit, a remote control receiver circuit, a motor control circuit, a motor torque control circuit, a shunt measurement circuit, a current indication circuit, a power supply circuit, and an external power supply Interface, charging circuit composition;

[0022] The right end of the movable a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com