Polymeric thin film polarization method and device, polarized film, and electronic device

A polymer thin film and thin film technology, applied in piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, electrical components, etc., can solve the problem of low pass rate of thin film production and achieve Large-scale production, strong piezoelectric effect, and the effect of avoiding breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

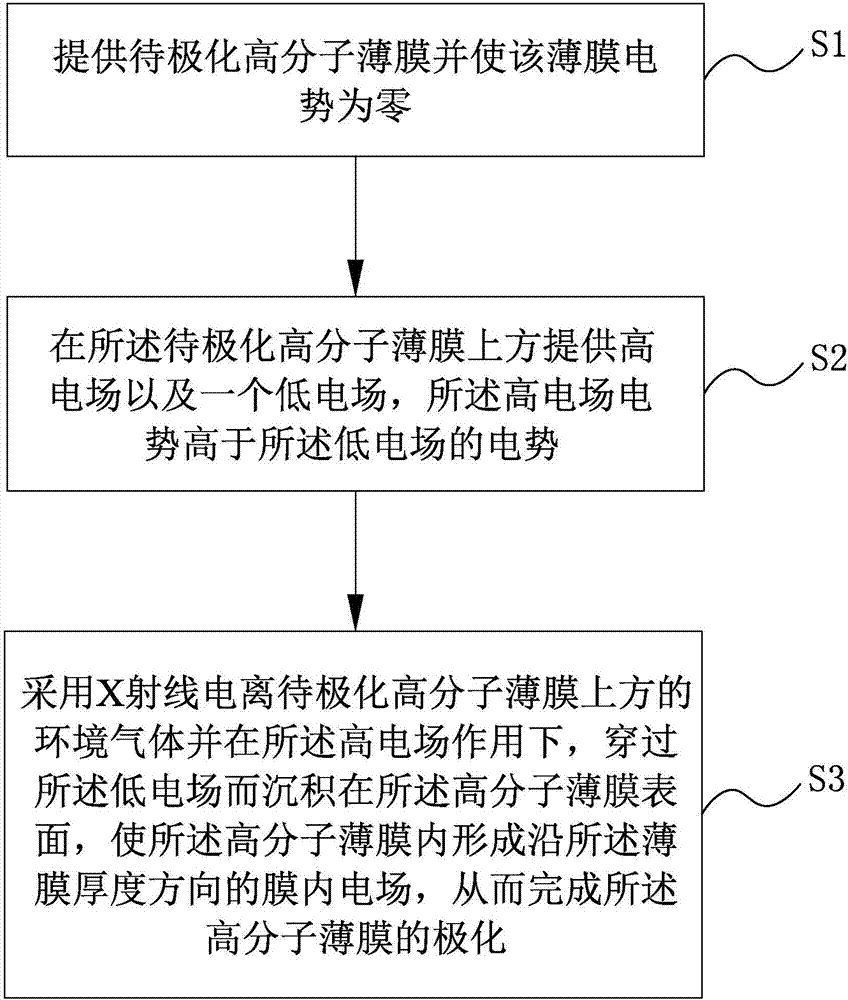

[0036] like figure 1 Shown, a polymer film polarization method, comprising:

[0037] Step S1: providing a polymer film to be polarized and making the film potential zero;

[0038] Step S2: providing a high electric field and a low electric field above the polymer film to be polarized, the potential of the high electric field is higher than the potential of the low electric field;

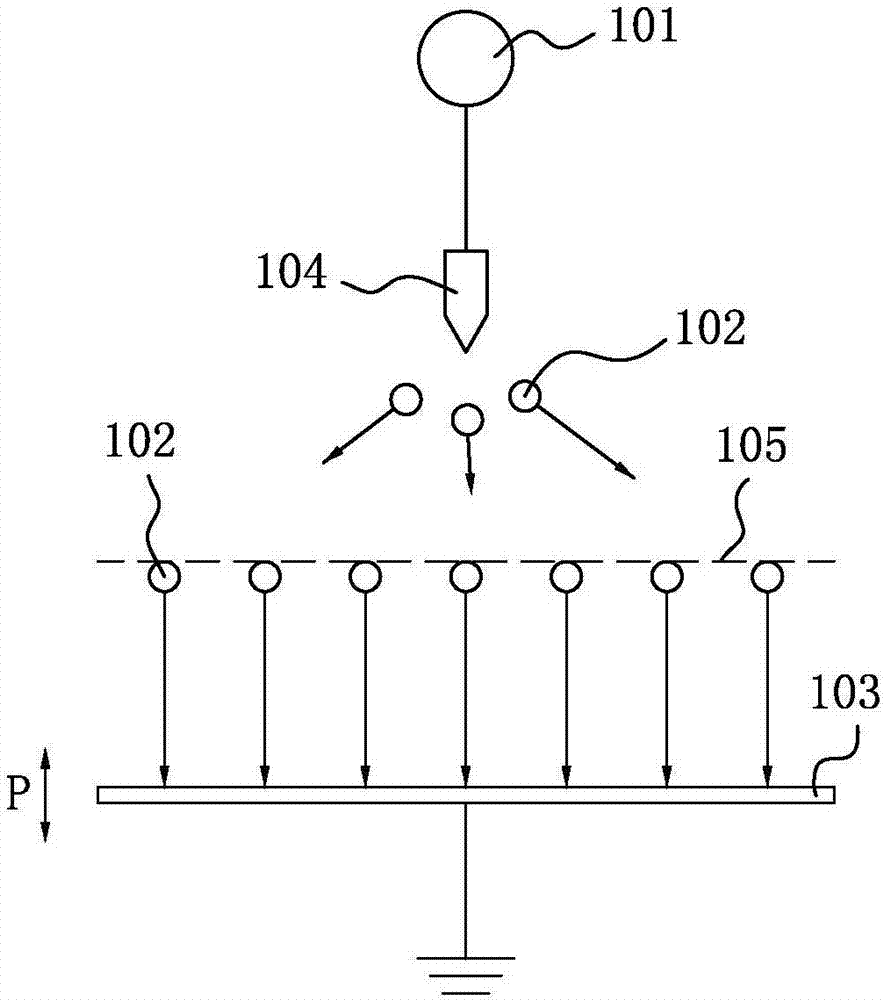

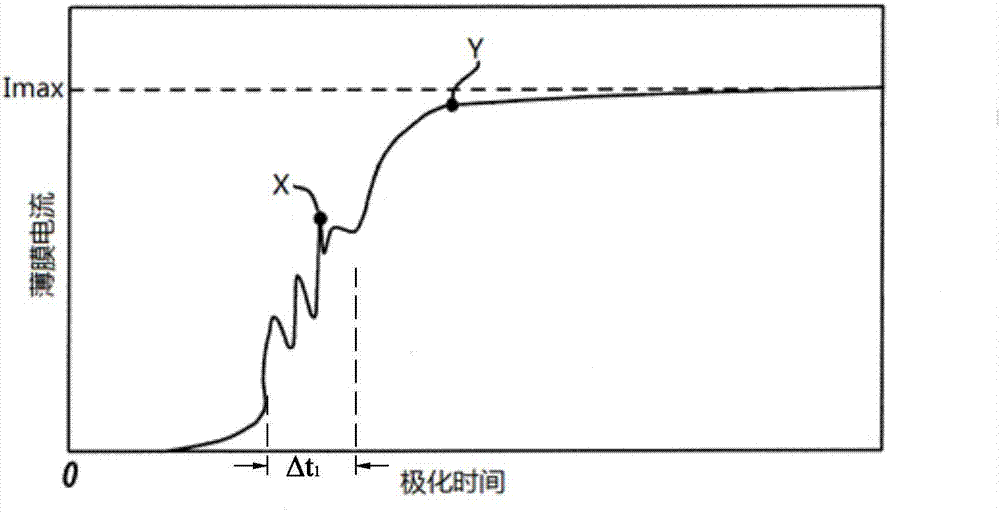

[0039] Step S3: using X-rays to ionize the ambient gas above the polymer film to be polarized and depositing it on the surface of the polymer film through the low electric field under the action of the high electric field, so that The electric field inside the film along the thickness direction of the film completes the polarization of the polymer film.

[0040] A method for polarizing a polymer film provided by the present invention uses X-rays to ionize the ambient gas above the polymer film to be polarized and passes through the low electric field to deposit on the polymer film under the action...

Embodiment 2

[0053] The present invention also provides a polarized film, which is prepared by the polymer film polarized method provided in Example 1. As described in Embodiment 1, the polarized film provided by the present invention has a strong piezoelectric effect and a long service life. And because the polarized film is a polymer film, such as a ferroelectric polymer film, which is polarized after being formed in situ on the surface of the substrate, the thickness of the polarized film is less than 9 μm, reducing the overall thickness of the device including this polarized film , which can better meet the needs of the market.

Embodiment 3

[0055]The present invention also provides an electronic device, which includes a base and a polarizing film formed on the base in situ. Since the polarized film has a strong piezoelectric effect, the application of the electronic device is effectively broadened and its competitiveness is enhanced. Electronic devices with piezoelectric effect are widely used in the field of sensors, and will be applied to communication devices such as mobile phones and tablet computers. Since the thickness of the polarizing film is less than 9 μm, it is more suitable for the current trend of light and thin communication equipment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com