Temperature control method and temperature control system

A temperature control method and technology of a temperature control system, which are applied in the direction of temperature control, control/regulation system, non-electric variable control, etc., can solve the problems of high operating frequency of power switch tubes, increased volume and weight, large switching loss, etc. The effect of electrical stress, continuous current and saving volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

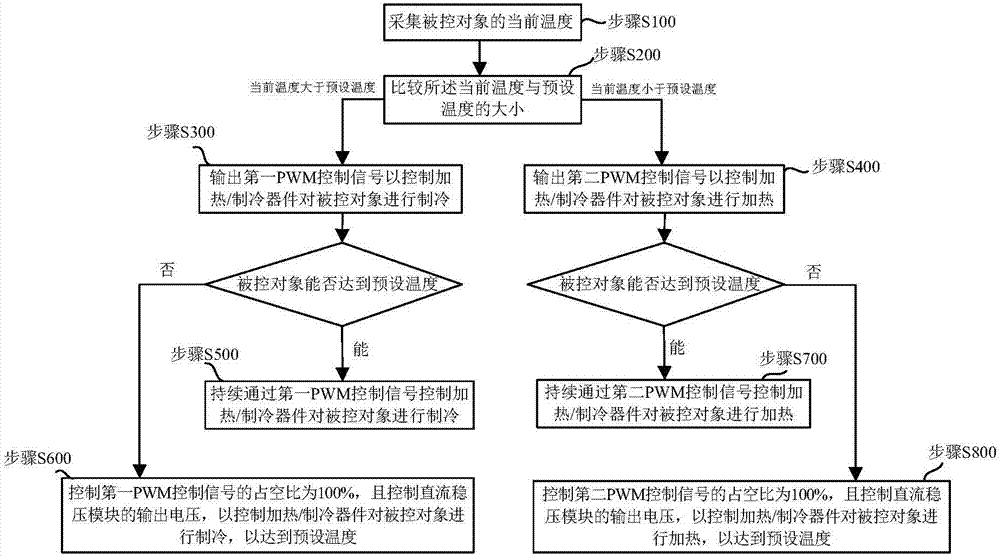

[0026] image 3 It is a flowchart of the temperature control method provided in Embodiment 1 of the present invention. Embodiment 1 of the present invention provides a temperature control method, including the following steps:

[0027] Step S100, collecting the current temperature of the controlled object.

[0028] In this embodiment, the controlled object is a laser device. Those skilled in the art can understand that the controlled object may also be other devices requiring temperature control. A temperature sensor is set on the laser device to collect the current temperature of the laser device.

[0029] Step S200 , comparing the current temperature with the preset temperature, if the current temperature is higher than the preset temperature, go to step S300 ; if the current temperature is lower than the preset temperature, go to step S400 .

[0030] The laser device has its rated operating temperature, which is the preset temperature mentioned above. If the laser device...

Embodiment 2

[0041] Figure 4 It is a flow chart of the temperature control method provided in Embodiment 2 of the present invention. Embodiment 2 of the present invention provides a temperature control method, including the following steps:

[0042] Step S100, collecting the current temperature of the controlled object.

[0043] In this embodiment, the controlled object is a laser device. Those skilled in the art can understand that the controlled object may also be other devices requiring temperature control. A temperature sensor is set on the laser device to collect the current temperature of the laser device.

[0044] Step S210, perform PID calculation according to the deviation between the current temperature and the preset temperature, and obtain the PID calculation value.

[0045] Step S220, compare the PID calculation value with the preset first threshold, if the PID calculation value is greater than or equal to the first threshold, go to step S300; if the PID calculation value i...

Embodiment 3

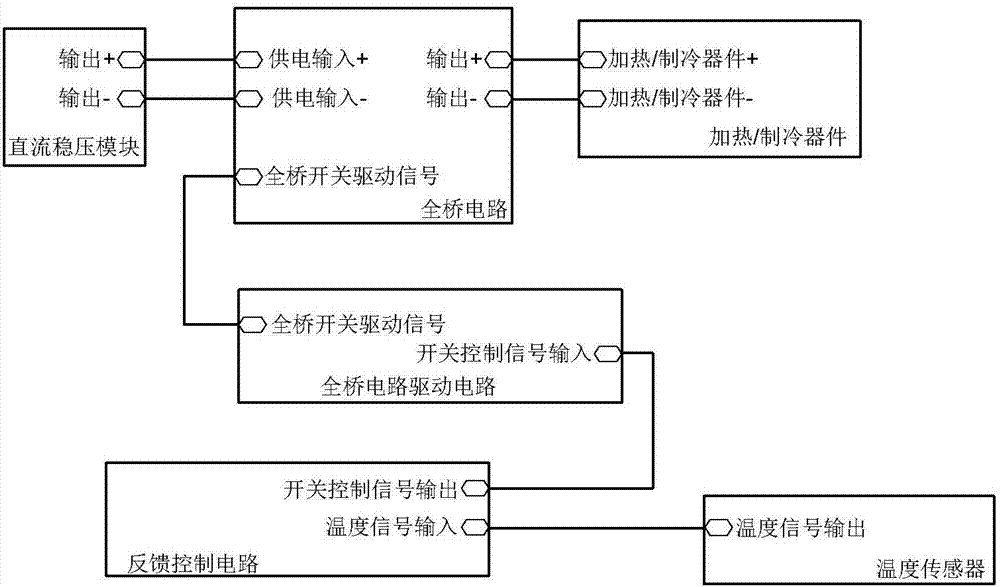

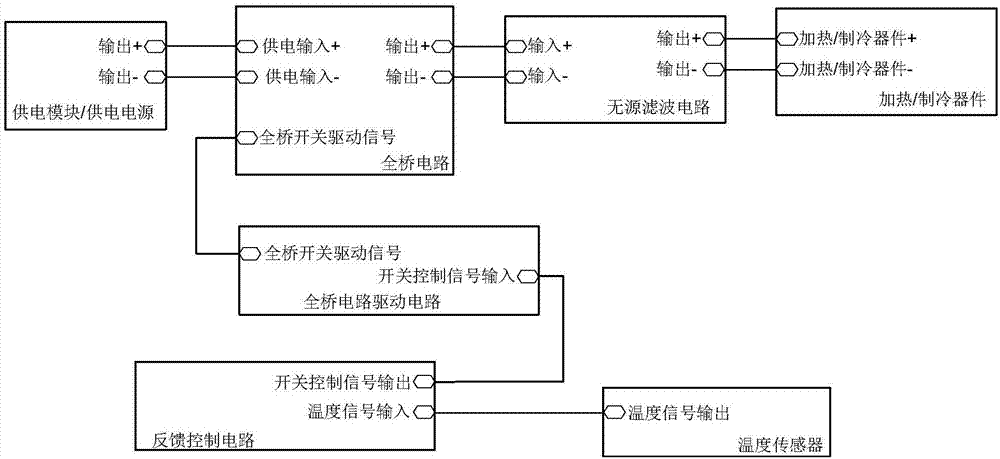

[0066] Figure 5 It is a structural block diagram of the temperature control system provided by Embodiment 3 of the present invention, such as Figure 5 As shown, Embodiment 3 of the present invention provides a temperature control system, including a DC voltage stabilization module, a full bridge circuit, a full bridge circuit drive circuit, a heating / cooling device, a main control module and a temperature sensor set on the controlled object .

[0067] Wherein, the temperature sensor is connected with the input terminal of the main control module, and is used for collecting the current temperature of the controlled object.

[0068] The first PWM control output end of the main control module is connected with the first control input end of the full bridge circuit driving circuit; the second PWM control output end of the main control module is connected with the second control input end of the full bridge circuit driving circuit; The adjustment control terminal of the module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com