ABS control system based on automobile brake test bed

A control system and automobile braking technology, applied in the mechanical field, can solve the problems of inability to determine the influence of ABS, excluding ABS, etc., and achieve the effect of accurate and reliable measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

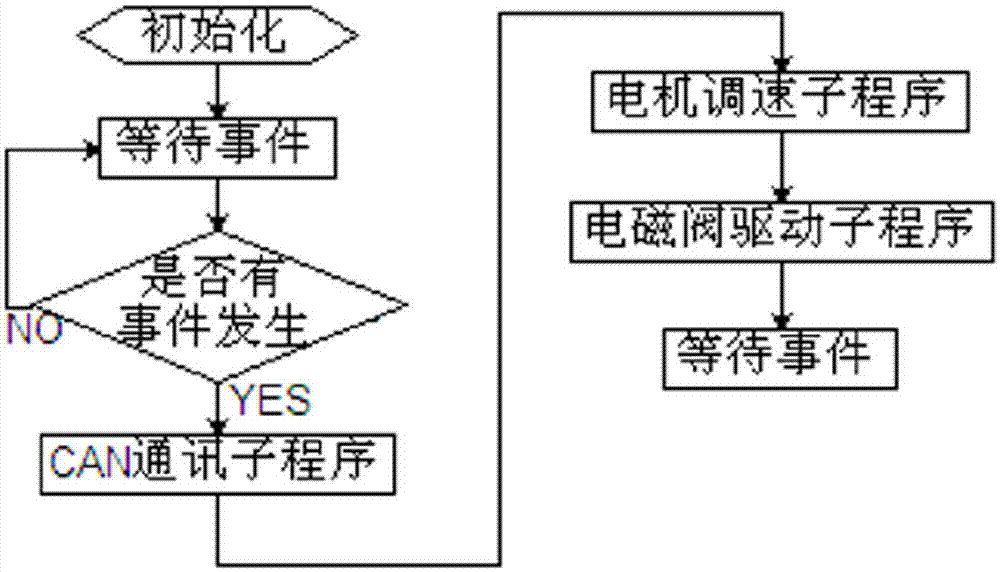

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

[0016] like figure 1 , The MCU of the control system chooses PIC18F2580 of PIC series. PIC18F2580 integrates CAN controller module and PWM module on the chip, which can reduce the number of chips on the circuit board and simplify programming.

[0017] The control system uses Freescale's high-end driver chip MC33289 to drive the hydraulic solenoid valve. This chip is mainly used in the automotive field to drive solenoid valves and other typical inductive loads. This device contains two power output switches in the same surface mount package, which can Directly interface with PIC18F2580 for input control and output diagnostic monitoring. Each output peak current is 5A, has independent over-current, over-voltage diagnosis and protection, and has over-temperature shutdown performance.

[0018] The DC motor speed regulation module of the control system uses LMD18200 of NI ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com