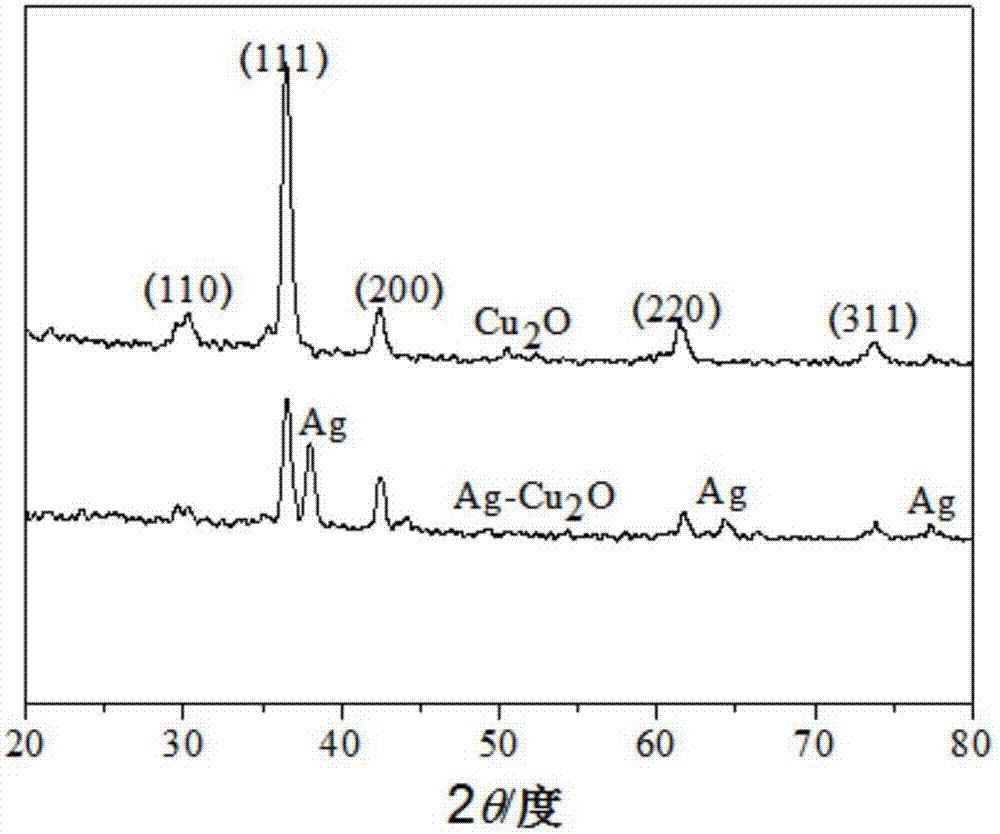

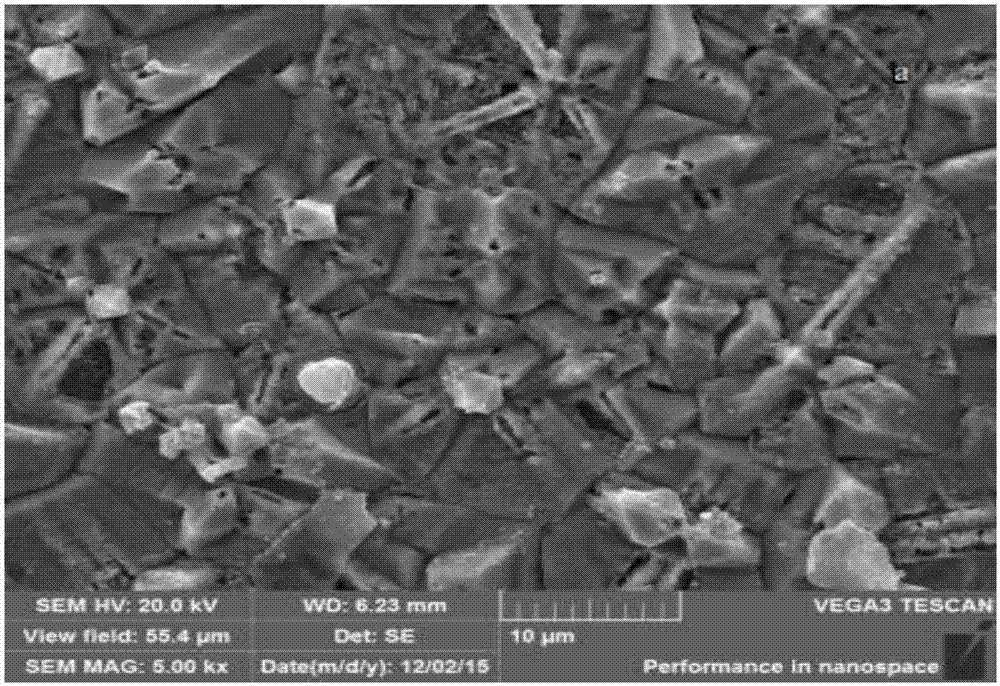

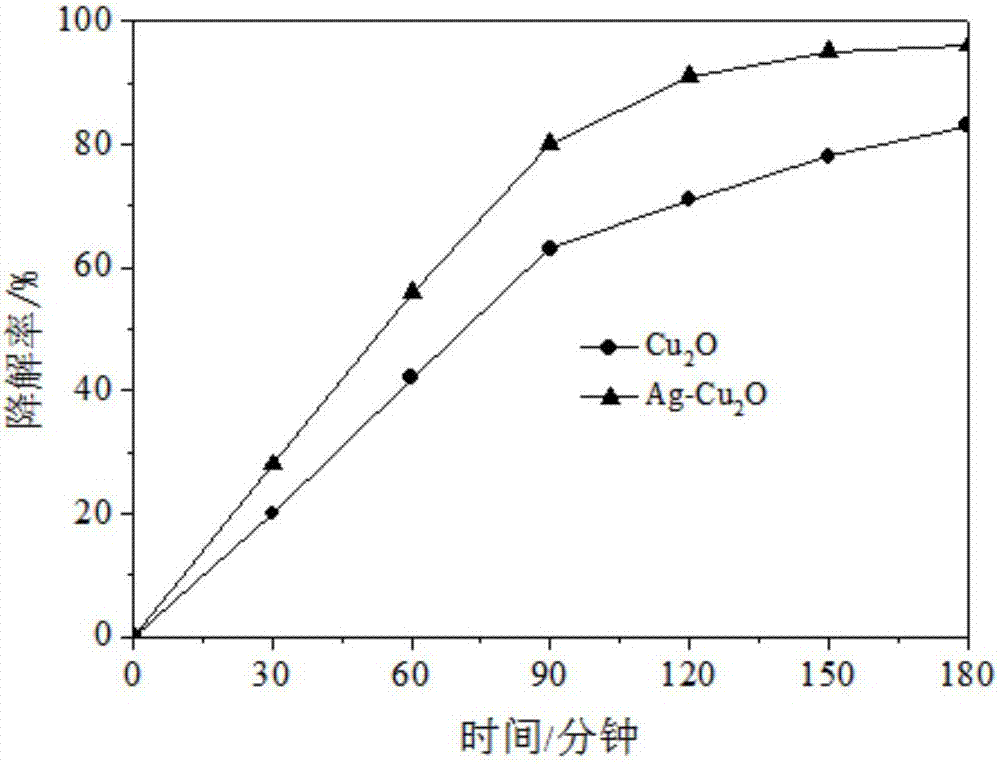

Preparation method of nanometer cuprous oxide photocatalytic material based on silver modification

A nano-cuprous oxide, photocatalytic material technology, applied in electrodes, electrolysis processes, electrolysis components, etc., can solve the problems of not significantly improving the photoelectric conversion efficiency of semiconductor materials, the electron-hole recombination rate, and the complex operation, and achieve excellent performance. Operability and applicability, simple operation, the effect of overcoming technical difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A kind of preparation method of nano-cuprous oxide photocatalytic material based on silver modification of the present invention, specifically implement according to the following steps:

[0056] Step 1, prepare Cu 2 O film;

[0057] Clean the ITO conductive glass with acetone and ethanol sequentially in the ultrasonic instrument, use the cleaned ITO conductive glass as the working electrode, the reference electrode and the counter electrode are calomel electrode and platinum electrode respectively; 0.01mol / L copper sulfate solution and 0.1mol / L lactic acid solution, measure the configured copper sulfate solution 100mL, measure the configured lactic acid solution 50mL, put the two solutions under the ultrasonic electric power of 300W, Mix under ultrasonic conditions with a working frequency of 40KHz, let stand for 10min, and prepare Cu 2 O electrolyte; for the prepared Cu 2 Add NaOH solution with a concentration of 4 mol / L to the O electrolyte to adjust the pH to 10....

Embodiment 2

[0060] A kind of preparation method of nano-cuprous oxide photocatalytic material based on silver modification of the present invention, specifically implement according to the following steps:

[0061] Step 1, prepare Cu 2 O film;

[0062] Clean the ITO conductive glass with acetone and ethanol sequentially in the ultrasonic instrument, use the cleaned ITO conductive glass as the working electrode, the reference electrode and the counter electrode are calomel electrode and platinum electrode respectively; 0.03mol / L copper sulfate solution and 0.7mol / L lactic acid solution, measure 100mL of the configured copper sulfate solution and 40mL of the configured lactic acid solution. Mix under ultrasonic conditions with a working frequency of 50KHz, let stand for 5min, and prepare Cu 2 O electrolyte; for the prepared Cu 2 Add NaOH solution with a concentration of 4.5 mol / L to the O electrolyte to adjust the pH to 10.5; the pH-adjusted electrolyte was deposited in an electrochemica...

Embodiment 3

[0065] A kind of preparation method of nano-cuprous oxide photocatalytic material based on silver modification of the present invention, specifically implement according to the following steps:

[0066] Step 1, prepare Cu 2 O film;

[0067] Clean the ITO conductive glass with acetone and ethanol sequentially in the ultrasonic instrument, use the cleaned ITO conductive glass as the working electrode, the reference electrode and the counter electrode are calomel electrode and platinum electrode respectively; 0.05mol / L copper sulfate solution and 0.8mol / L lactic acid solution, measure 100mL of the configured copper sulfate solution, 38mL of the configured lactic acid solution, put the two solutions under the ultrasonic electric power of 500W, Mix under ultrasonic conditions with a working frequency of 50KHz, let stand for 7.5min, and prepare Cu 2 O electrolyte; for the prepared Cu 2 Add NaOH solution with a concentration of 5mol / L to the electrolyte of O to adjust the pH to 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com