A kind of phosphorus pig iron carburizing method

A technology of phosphorus pig iron and carbon balls, which is applied in the field of aluminum electrolysis production, can solve the problems of destroying the chemical composition of phosphorus pig iron, affecting the performance of phosphorus pig iron, and impure electrolytic residual electrode particles, so as to achieve good fluidity of phosphorus pig iron water and reduce material Flying loss, good effect of carbon increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

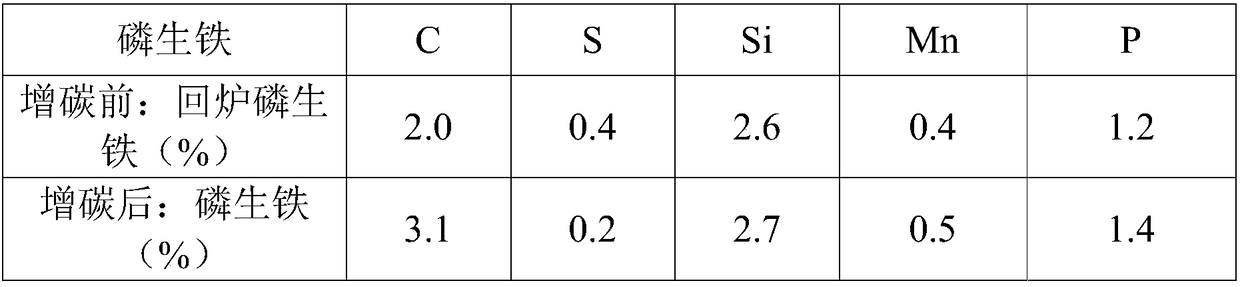

Image

Examples

preparation example Construction

[0032] The embodiment of the present invention also provides a method for preparing recarburized balls for prebaked anode casting, which mainly includes the following steps:

[0033]S1. Sieving and crushing: Sieve ordinary cathode milling flour, crush the sieved material, and pass through a 5mm sieve to obtain carbon material cathode milling flour, that is, a carburant. The purpose of sieving and crushing is to obtain Homogenous cathode milling flour.

[0034] S2. Ingredients: Prepare the raw materials by weight percentage. The raw materials include 95.5% to 98.5% of cathode milling flour, 1.0% to 3.5% of binder and 0.5% to 1.0% of carbonate, wherein the binder consists of Composed of inorganic binder and organic binder with a mass ratio of 1:1.5 to 2, the inorganic binder preferably includes alkali metal silicates, fluorosilicates, aluminosilicates, phosphates, metal alkoxides, At least one of magnesium fluorosilicate, ammonium chloride, ammonium phosphate, zinc oxide, alumi...

Embodiment 1

[0058] Embodiment 1 provides a prebaked anode casting recarburizing ball, which is obtained by the following preparation steps:

[0059] Prepare raw materials: 9.65kg carbon material (selected with a true density of 2.02g / cm 3 , fixed carbon content 98.5%, cathode milling flour with a particle size below 5mm, the cathode milling flour is obtained by sieving ordinary cathode milling flour, crushing the sieve, and passing through a 5mm sieve), 0.3kg binder , the binder is configured according to the ratio of sodium silicate: (starch + sodium carboxymethyl cellulose) = 1:1.5, 0.05% melting agent (sodium carbonate is selected).

[0060]Preparation process: mix starch, sodium carboxymethylcellulose and water at 100°C in a mass ratio of 7:1, add sodium silicate and sodium carbonate under rapid stirring, stir for 0.5h, and cool naturally to room temperature to obtain Bonding material; Sprinkle the cathode milling flour into the bonding material, stir for 5 minutes to prepare a carbo...

Embodiment 2

[0070] Embodiment 2 provides a prebaked anode casting recarburizing ball, which is obtained by the following preparation steps:

[0071] Prepare raw materials: 9.8kg carbon material (selected with a true density of 2.08g / cm 3 , fixed carbon content 99%, cathode milling flour with a particle size below 5mm, the cathode milling flour is obtained by sieving ordinary cathode milling flour, crushing the sieve, and passing through a 5mm sieve), 0.15kg binder , the binder is configured according to the ratio of sodium fluorosilicate: (starch + polyvinyl alcohol) = 1:2, 0.05kg of melting agent (sodium carbonate is selected).

[0072] Preparation process: Mix starch, sodium carboxymethylcellulose and water at 100°C in a mass ratio of 10:1, add sodium silicate under rapid stirring, and add melting accelerator sodium carbonate, stir for 1 hour, and cool naturally to room temperature. Obtain the bonding material; sprinkle the cathode milling flour into the bonding material, and stir for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com