A leather uniform dyeing device

A technology for uniform dyeing and leather, applied in the field of dyeing devices, which can solve the problems of uneven dyeing and slow drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

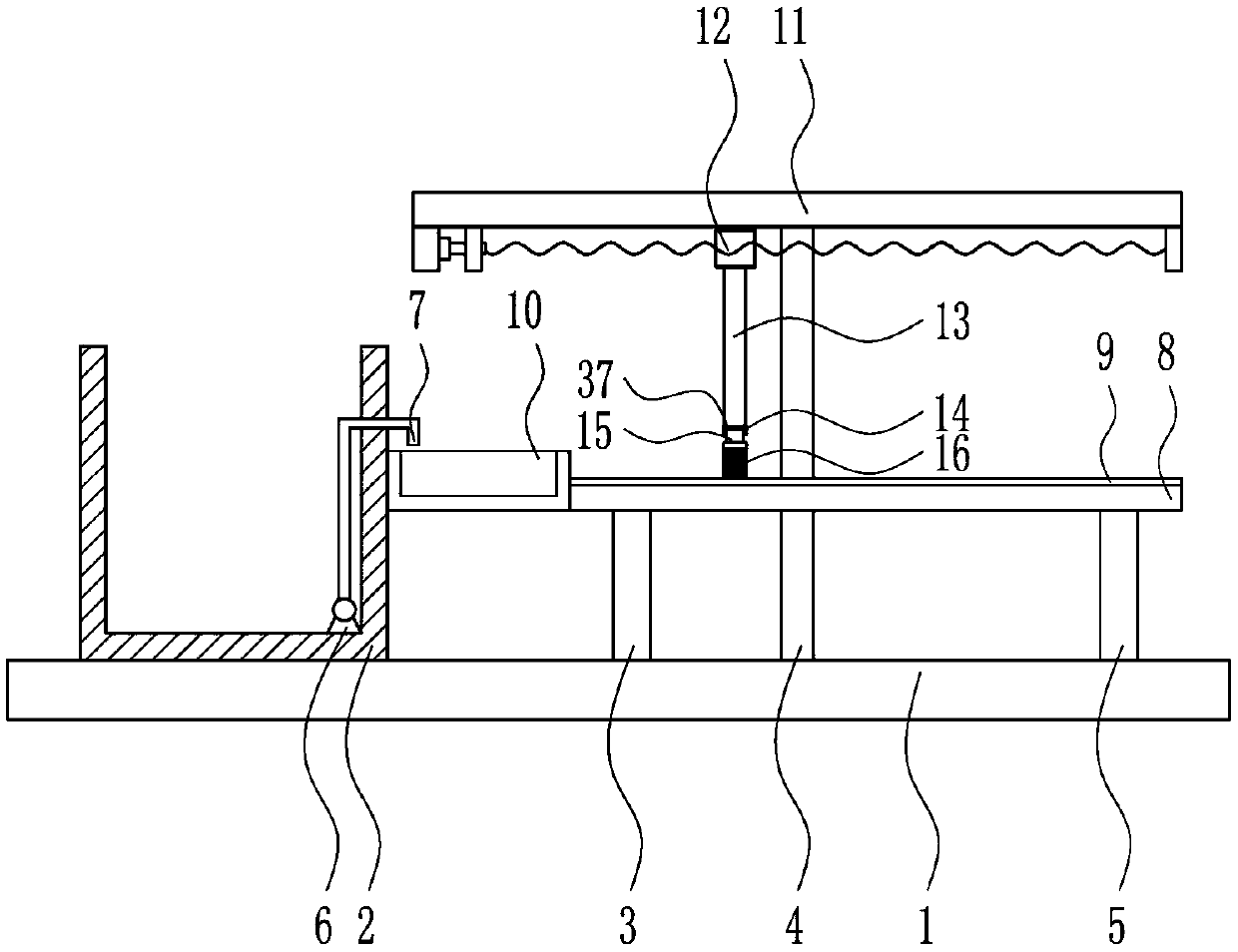

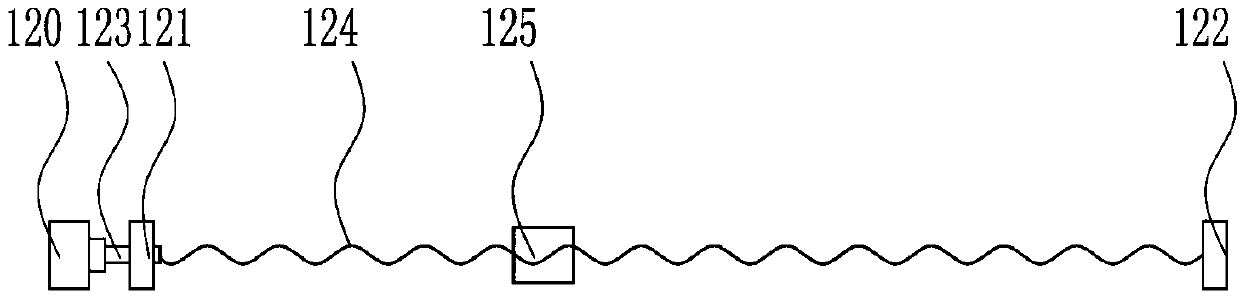

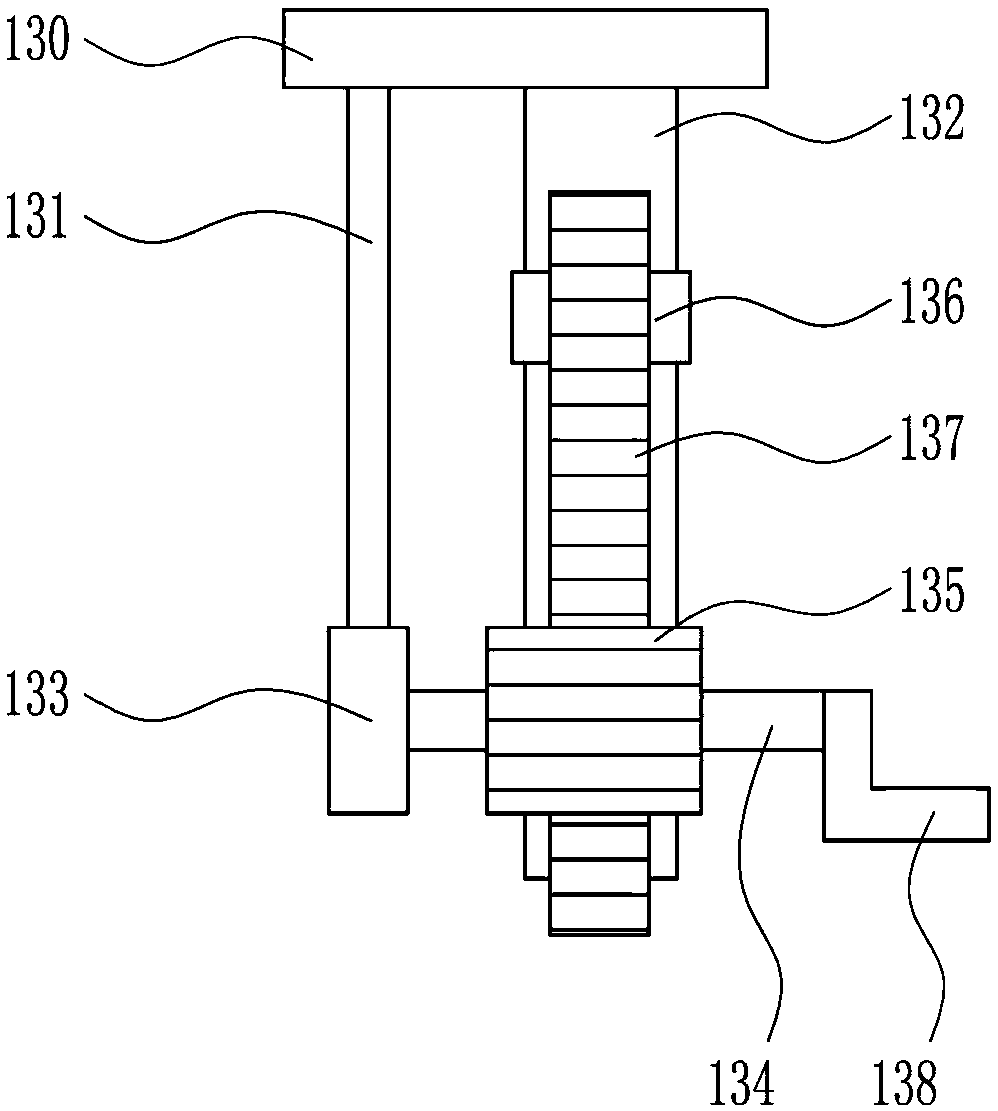

[0037] A leather uniform dyeing device, such as Figure 1-7 As shown, it includes bottom plate 1, dye box 2, left bracket 3, first bracket 4, right bracket 5, water pump 6, first hard pipe 7, table top 8, hard sponge 9, dipping material box 10, top plate 11 , left and right moving device 12, up and down moving device 13, fixed plate 14, fixed block 15 and soft brush 16, base plate 1 top is provided with dye box 2, left support 3, first support 4 and right support 5 successively from left to right , the left support 3 and the top of the right support 5 are connected with a desktop 8, the first support 4 is located behind the desktop 8, the top of the desktop 8 is provided with a hard sponge 9, the left side of the desktop 8 is connected with a dipping box 10, and the top of the first support 4 is connected There is a top plate 11, the bottom of the top plate 11 is provided with a left and right moving device 12, the bottom of the left and right moving device 12 is provided with...

Embodiment 2

[0039] A leather uniform dyeing device, such as Figure 1-7 As shown, it includes bottom plate 1, dye box 2, left bracket 3, first bracket 4, right bracket 5, water pump 6, first hard pipe 7, table top 8, hard sponge 9, dipping material box 10, top plate 11 , left and right moving device 12, up and down moving device 13, fixed plate 14, fixed block 15 and soft brush 16, base plate 1 top is provided with dye box 2, left support 3, first support 4 and right support 5 successively from left to right , the left support 3 and the top of the right support 5 are connected with a desktop 8, the first support 4 is located behind the desktop 8, the top of the desktop 8 is provided with a hard sponge 9, the left side of the desktop 8 is connected with a dipping box 10, and the top of the first support 4 is connected There is a top plate 11, the bottom of the top plate 11 is provided with a left and right moving device 12, the bottom of the left and right moving device 12 is provided with...

Embodiment 3

[0042] A leather uniform dyeing device, such as Figure 1-7 As shown, it includes bottom plate 1, dye box 2, left bracket 3, first bracket 4, right bracket 5, water pump 6, first hard pipe 7, table top 8, hard sponge 9, dipping material box 10, top plate 11 , left and right moving device 12, up and down moving device 13, fixed plate 14, fixed block 15 and soft brush 16, base plate 1 top is provided with dye box 2, left support 3, first support 4 and right support 5 successively from left to right , the left support 3 and the top of the right support 5 are connected with a desktop 8, the first support 4 is located behind the desktop 8, the top of the desktop 8 is provided with a hard sponge 9, the left side of the desktop 8 is connected with a dipping box 10, and the top of the first support 4 is connected There is a top plate 11, the bottom of the top plate 11 is provided with a left and right moving device 12, the bottom of the left and right moving device 12 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com