Polymer microemulsion system for deep profile control of oil reservoir and preparation method thereof

A polymer, deep technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problem of reducing oil displacement effect, poor oil-water interface activity, aquatic toxicity, skin irritation, poor teratogenicity, and biodegradability. and other problems, to achieve the effect of narrow particle size distribution, enhanced interfacial activity, and improved oil recovery as required by field operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1. Synthesis of palmitic acid diethanolamide surfactant:

[0047] (a) Synthesis of methyl palmitate

[0048] Add 100g of palmitic acid (alias: palmitic acid, hexadecanoic acid) into the three-necked flask, then add 50mL of methanol and 0.8g of sodium hydroxide, install a reflux and stirring device, and control the reaction temperature at 60°C. Reaction 3h. After the reaction, excess methanol was distilled off and transferred to a separatory funnel. After standing still, the glycerol in the lower layer was separated, and the obtained crude fatty acid methyl ester was washed with water several times to a medium size, and then washed once with a saturated NaCl aqueous solution to obtain refined Fatty acid methyl ester, the calculated yield is 93.8%.

[0049] (b) synthesis of palmitic acid diethanolamide

[0050] Add 80g of methyl palmitate and 18g of diethanolamine into a three-necked flask, control the reaction temperature at 110°C, and react for 2h under full stirring...

Embodiment 2

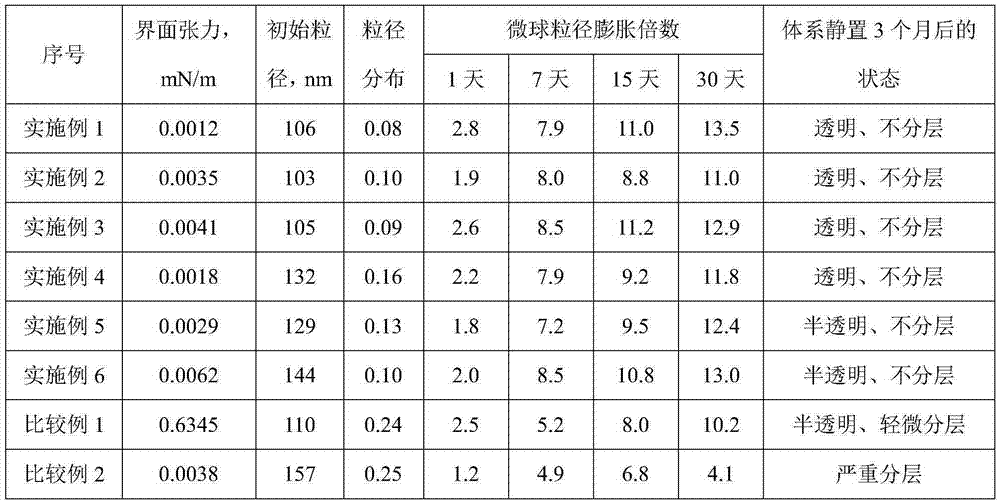

[0062] The synthesis of the palmitic acid diethanolamide surfactant and the preparation process of the microemulsion system for deep regulation and flooding are the same as in [Example 1], except that the dosages of the emulsifiers palmitic acid diethanolamide and Span80 are changed to 13g and 11g respectively. The characterization method of the polymer microemulsion system and the polymer microspheres therein is the same as [Example 1], and the results are shown in Table 1.

Embodiment 3

[0064] The synthesis of the palmitic acid diethanolamide surfactant and the preparation process of the microemulsion system for deep regulation and flooding are the same as in [Example 1], except that the dosages of the emulsifiers palmitic acid diethanolamide and Span80 are changed to 6g and 18g respectively. The characterization method of the polymer microemulsion system and the polymer microspheres therein is the same as [Example 1], and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com