Micro-nano nozzle drawing-forging device and method integrating drawing and forging

A nozzle, micro-nano technology, applied in the direction of manufacturing tools, glass molding, glass re-molding, etc., to achieve the effects of convenient installation, improved reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

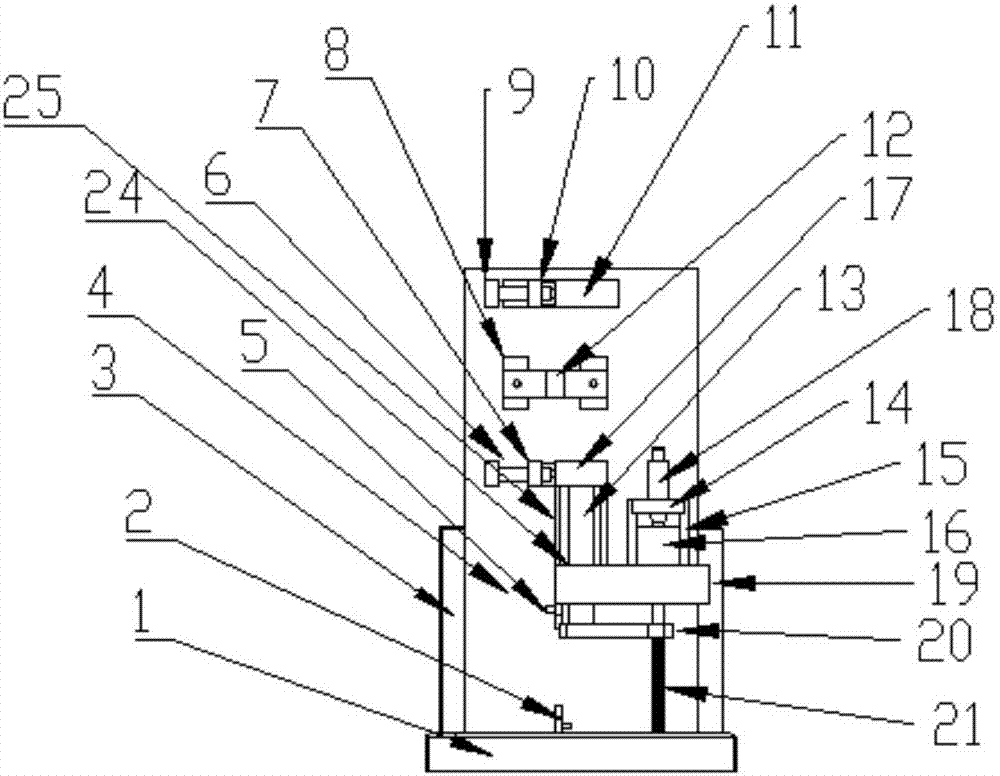

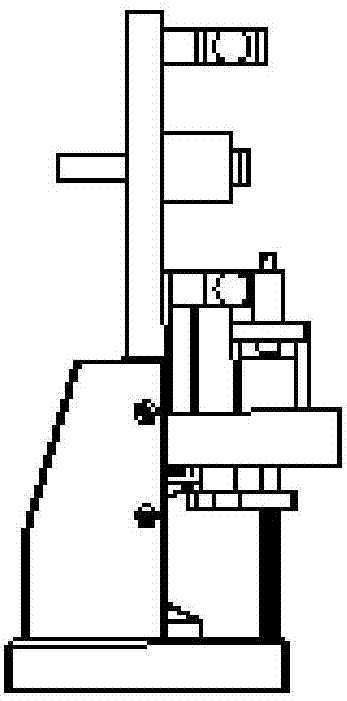

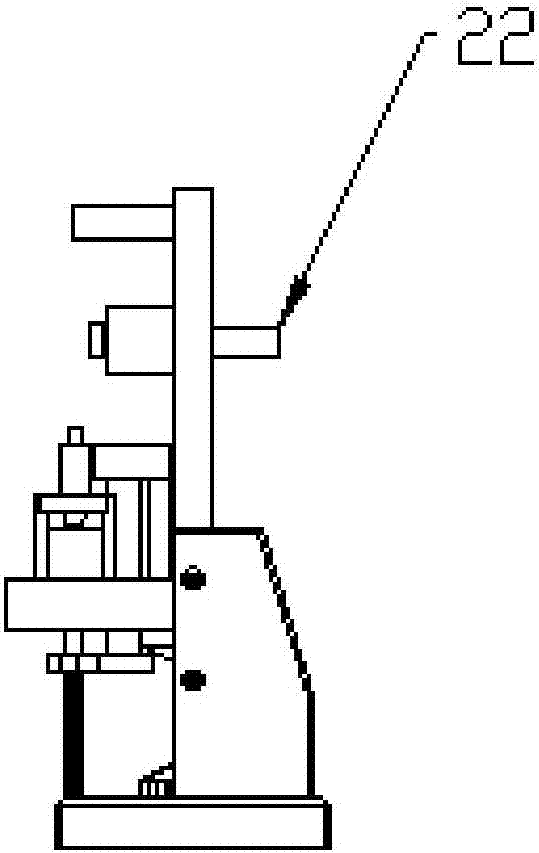

[0032] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

[0033] refer to Figure 1 to Figure 12 , a micro-nano nozzle drawing instrument device of the present invention, comprising a base 1, a side wall 3 and a back plate 4, on which a micro-needle clamping mechanism, a heating wire clamping mechanism and a drawing needle movement are arranged on the back plate 4 institutions, where:

[0034] The microneedle clamping mechanism is arranged on the upper part of the back plate 4, and is used to clamp one end of the glass tube;

[0035] The heating wire clamping mechanism is arranged in the middle of the back plate 4 for heating the glass tube;

[0036] The drawing needle moving mechanism is arranged at the lower part of the back plate 4, and is used to clamp the other end of the glass tube and drive the glass tube to move to realize the drawing process.

[0037] Specifically, the drawing pin movement mechanism include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com