Lithium battery production waste water treatment system

A technology for producing wastewater and treatment system, which is applied in biological water/sewage treatment, water/sewage treatment, flotation water/sewage treatment, etc. It can solve problems such as high operator requirements, difficulty in ensuring effluent quality, and complex wastewater composition. , to achieve good treatment effect, reduce operation difficulty and operating costs, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

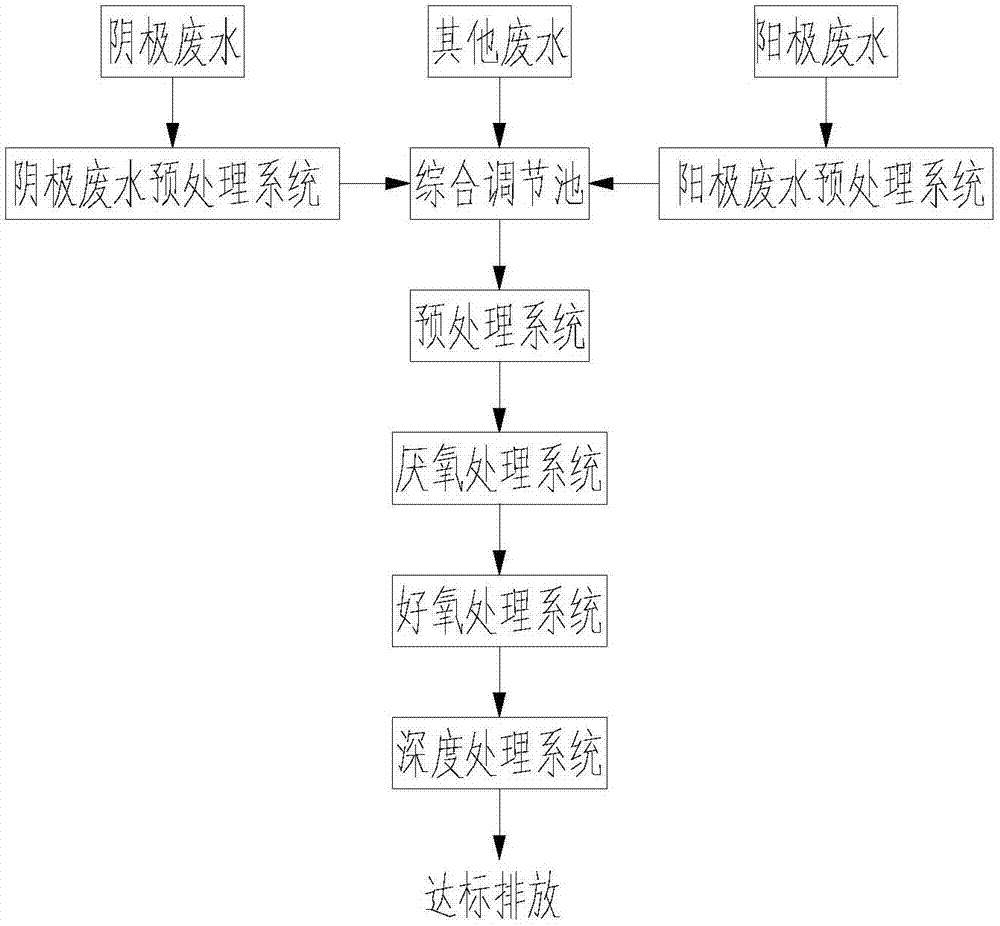

[0012] Below in conjunction with accompanying drawing, the present invention will be further described

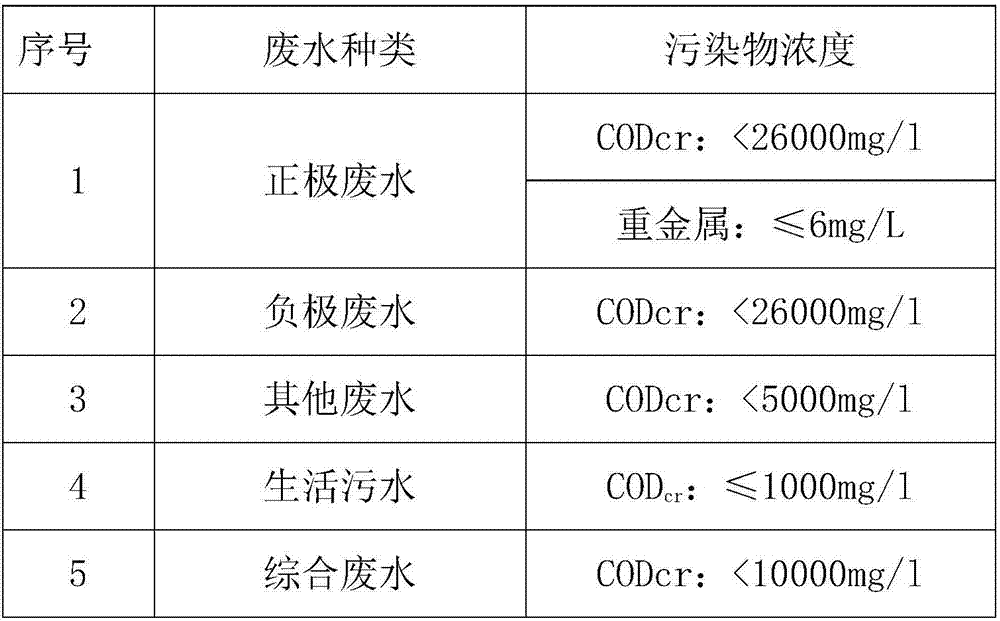

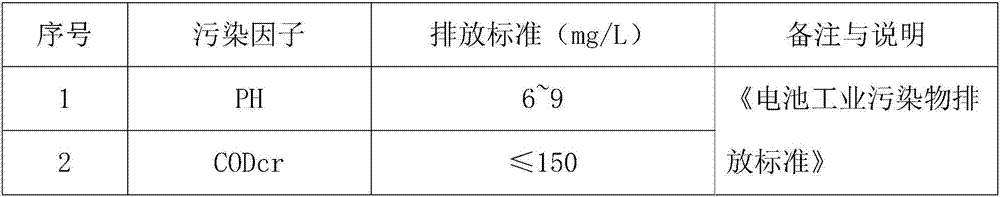

[0013] The cathode and anode wastewater produced by lithium battery production are pretreated by cathode and anode, and other sewage (domestic sewage, workshop flushing wastewater, etc.) are reconciled in the comprehensive adjustment tank at a ratio of 1:1:1.5. After pretreatment, anaerobic treatment, Discharge up to standard after aerobic treatment and advanced treatment,

[0014] Pretreatment is to add 1mg / L of PAM, 100mg / L of PAC for flocculation, adding H 2 SO 4 , NaO makes the pH of the pretreated sewage 6-9;

[0015] Anaerobic treatment adopts IC reactor for deep anaerobic treatment. Under the premise that the water temperature of deep anaerobic wastewater is 37±2℃, the volume load of influent COD is controlled at 6kgCODm 3 / d, the COD removal rate can reach more than 90%;

[0016] The aerobic treatment is a combination of activated sludge method and MBR membrane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com