Combined membrane technology-based high temperature high-salt petroleum production wastewater recycling method

A technology for high-temperature, high-salt, oil extraction wastewater, applied in mining wastewater treatment, chemical instruments and methods, water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

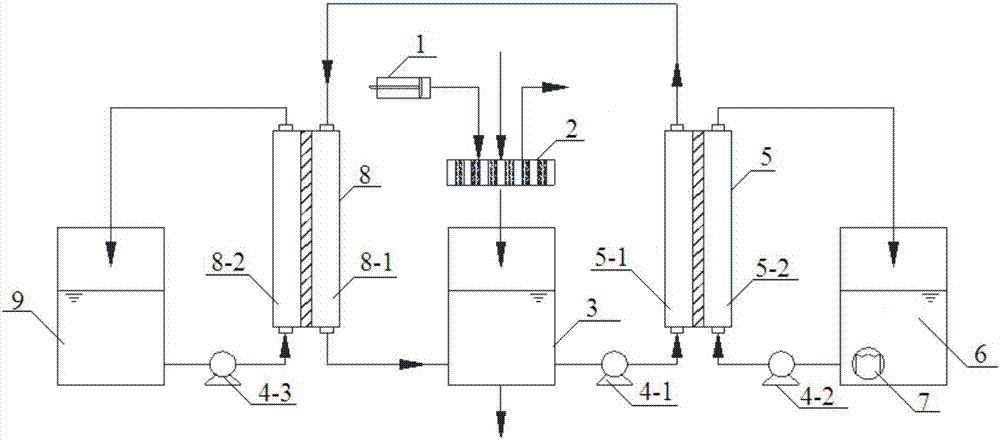

[0016] Specific implementation mode 1: In this implementation mode, the method for recycling and reusing high-temperature and high-salt oil production wastewater based on the combined membrane process is carried out according to the following steps:

[0017] 1. After being pressurized by the pressurization equipment 1, the wastewater from oil production enters the ceramic ultrafiltration membrane module 2 under the condition of a pressure of 0.05MPa-0.3MPa, and the filtered water enters the sump 3, reaching 50-70% of the volume of the sump. The ultrafiltration system is stopped, the oil in the filter cake layer is recovered, and the ceramic ultrafiltration membrane module 2 is cleaned;

[0018] 2. When the ultrafiltration system stops running, the forward osmosis and membrane distillation systems start to run, and the filtered water in the sump 3 enters the raw material liquid side 5-1 of the membrane distillation assembly 5 through the first water pump 4-1, and is cooled The ...

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment differs from Embodiment 1 in that the ceramic ultrafiltration membrane module 2 in step 1 has a pore size of 5KDa-0.1 μm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the material of the ceramic ultrafiltration membrane module 2 in step 1 is alumina, titania or zirconia. Others are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com