New energy electric car

An electric vehicle and new energy technology, applied in vehicle parts, vehicle safety arrangements, bumpers, etc., can solve the problem of insufficient safety and achieve good anti-collision effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

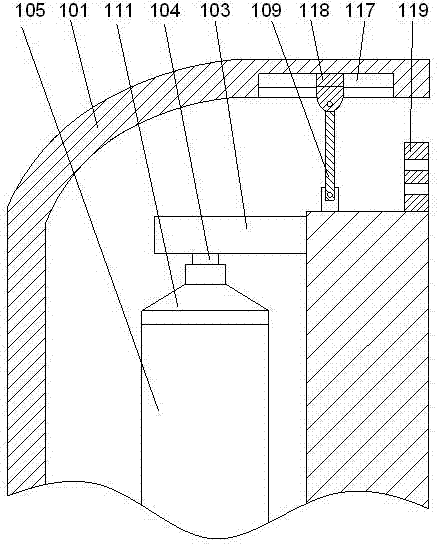

[0021] In this embodiment, in order to improve the anti-collision performance of the overall structure, preferably, open-shaped connecting pipes 111 are respectively provided at both ends of the sleeve 105, so that the connecting pipes 111 are sleeved on the Outside the beam 104, the inner diameter of the connecting pipe 111 near the end of the sleeve 105 is larger than the inner diameter of the other end, so that the connecting pipe is welded or connected to the two ends of the sleeve through a flange, or connected by other means , a torsion spring is arranged inside the connecting pipe 111, so that one end of the torsion spring is fixedly connected to the connecting pipe, and the other end is fixedly connected to the beam. When the sleeve 105 drives the connecting pipe 111 to rotate, it can Make described torsion spring torsion. By adopting the connecting pipe structure, the inner side of the connecting pipe is equipped with a torsion spring structure. When the casing is rel...

Embodiment 2

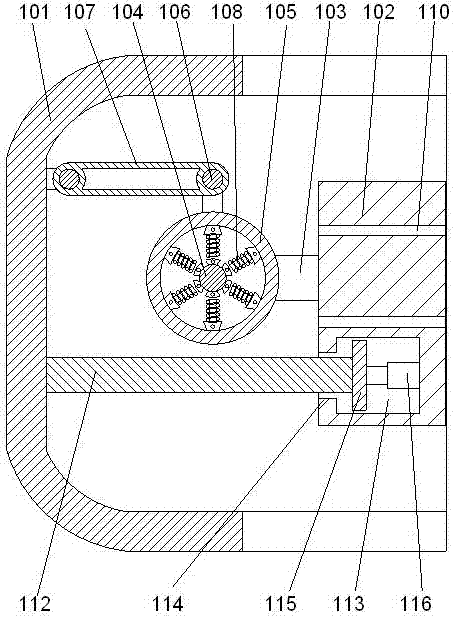

[0023] Since some bumpers are made of brittle materials, they are easily broken when they are impacted. When the buffer spring group inside the sleeve produces elastic force on the sleeve, the sleeve may be under the action of the buffer spring group. Reciprocating movement is generated, so that the front cover is easily broken under the reciprocating force. In this embodiment, in order to avoid the reciprocating movement of the sleeve when the buffer spring group exerts force on the sleeve, preferably, the front A buffer plate 112 is arranged on the end surface of the cover body 101 facing the rear cover body 102, so that the buffer plate is fixedly connected to the front cover body, and the buffer plate points to the rear cover body, and is arranged on the rear cover body 102. There is a sinking groove 113 corresponding to the position of the buffer plate 112, so that the buffer plate 112 can be inserted into the inside of the sinking groove 113, and a retaining edge 114 is p...

Embodiment 3

[0025] In this embodiment, in order to facilitate the mutual connection between the front cover and the rear cover, preferably, slide grooves are respectively provided on the end faces of the two ends of the front cover 101 facing the rear cover 102 117, make the length direction of the chute parallel to the length direction of the front cover, and the end of the connecting rod 109 away from the rear cover 102 is provided with a slider 118 capable of sliding along the chute 117, The slider 118 is rotatably connected to the connecting rod 109 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com