A sponge compressor

A compressor and sponge technology, applied in the field of sponge compression processing, can solve the problem of not being able to continuously compress the sponge into 3-5mm, and achieve the scientific and reasonable effect of the technical solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

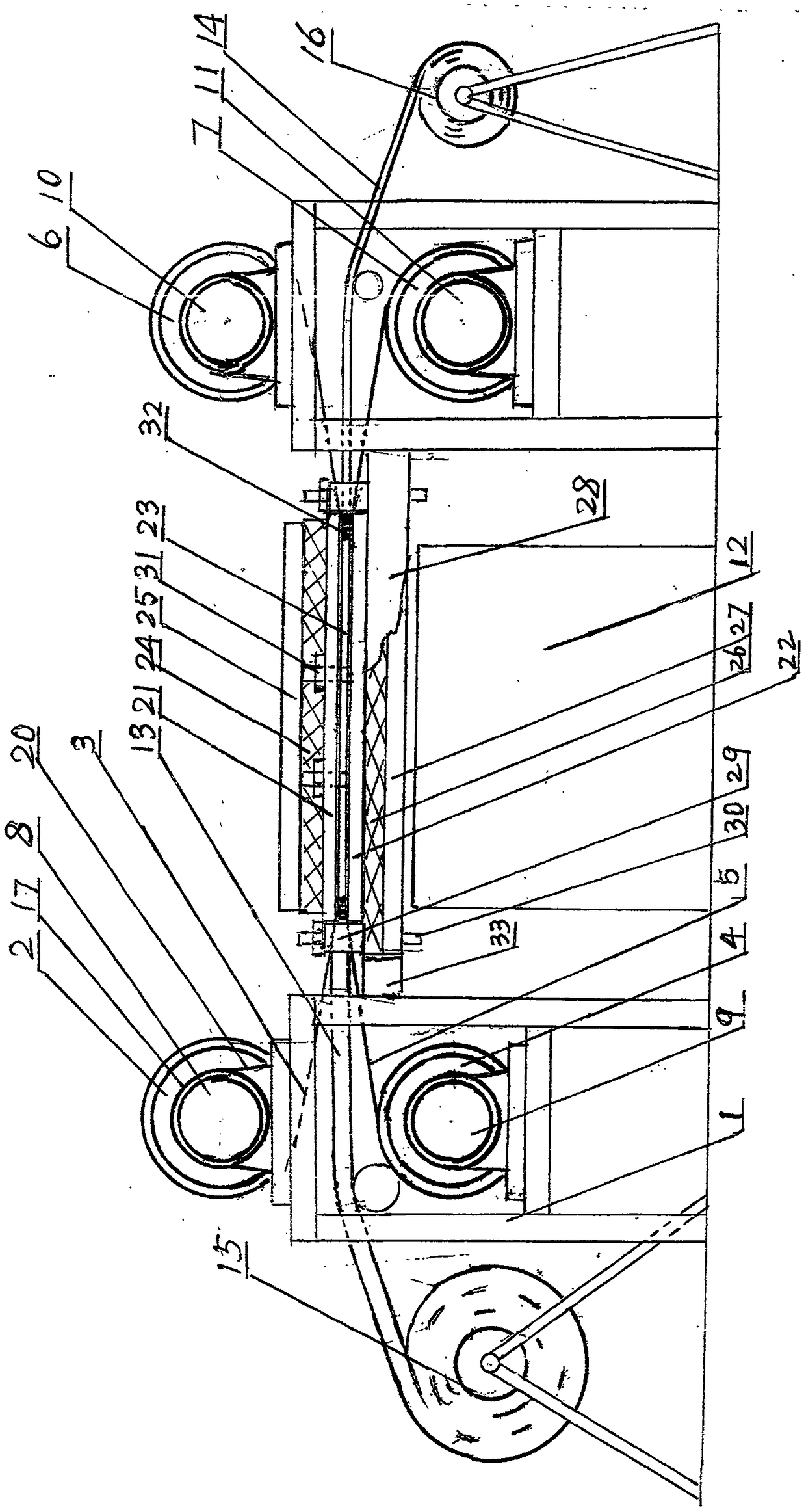

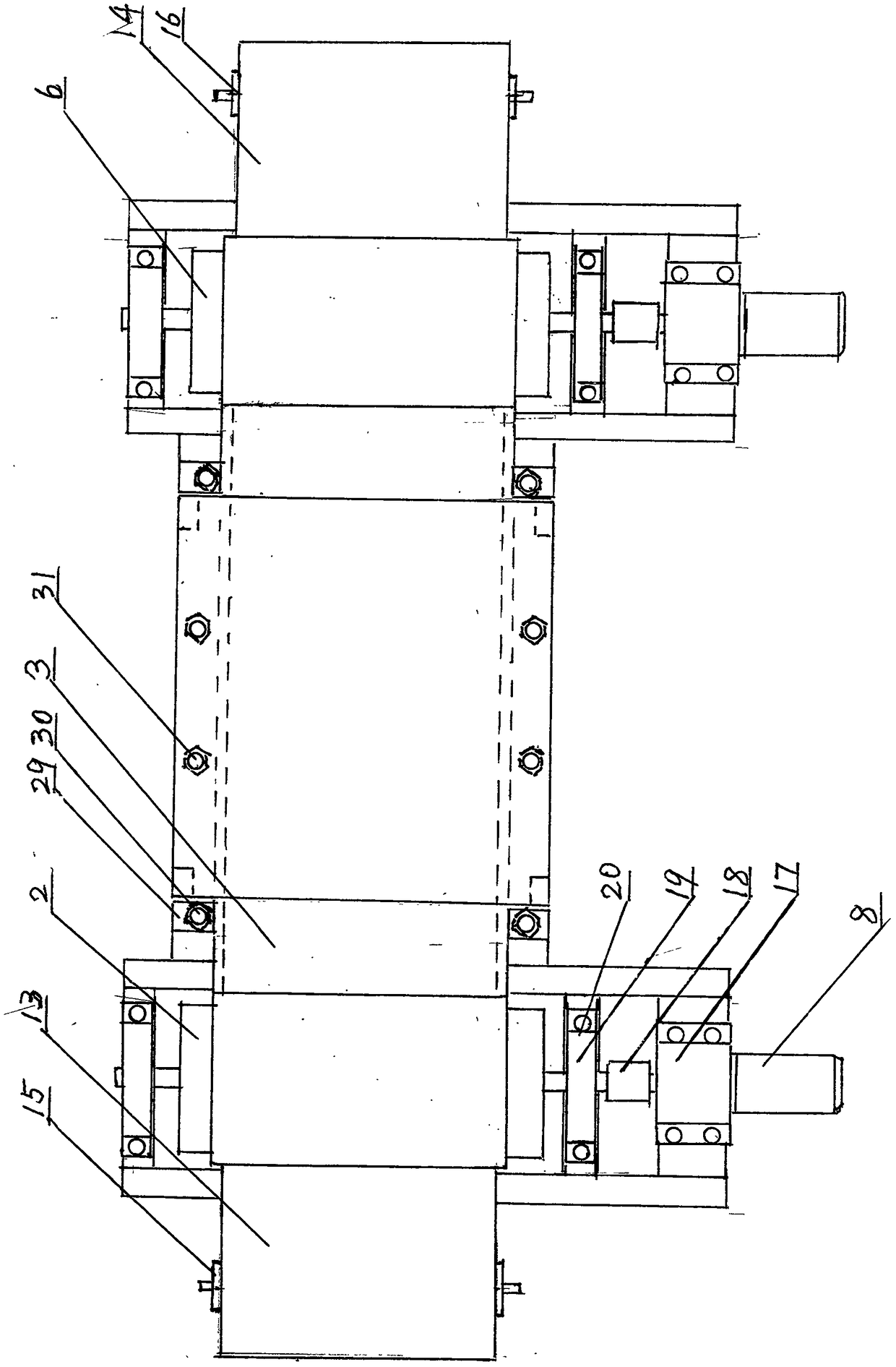

[0012] The accompanying drawings of the description show a specific embodiment of the present invention.

[0013] A sponge compressor comprises a frame 1, a sponge 13 before compression, a sponge 14 after compression, a sponge conveying and moving device, and a sponge heating and compressing device. The sponge conveying mobile device includes a sponge unwinding shaft 15 before compression, a sponge roll unwinding shaft 16 after compression, the first unwinding roller 2 installed on the top of the left frame, and the upper conveying entrainment belt 3 rolled on the first unwinding roller 2 , The second unwinding roller 4 installed on the lower part of the left frame, the lower conveying entrainment belt 5 rolls on the second unwinding roller 4, the first unwinding roller 6 installed on the upper part of the right frame, and the upper conveying entrainment belt 3 rolled on the second A roll puts on the roller 6, is installed in the second roll of the right frame bottom and puts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com