Gel propellant single droplet secondary crushing experimental device

A gel propellant and secondary crushing technology, applied in measuring devices, material inspection products, material thermal analysis, etc., can solve problems such as inconvenient operation and complicated equipment, and achieve reduced interference, good fluidity, simple and reliable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

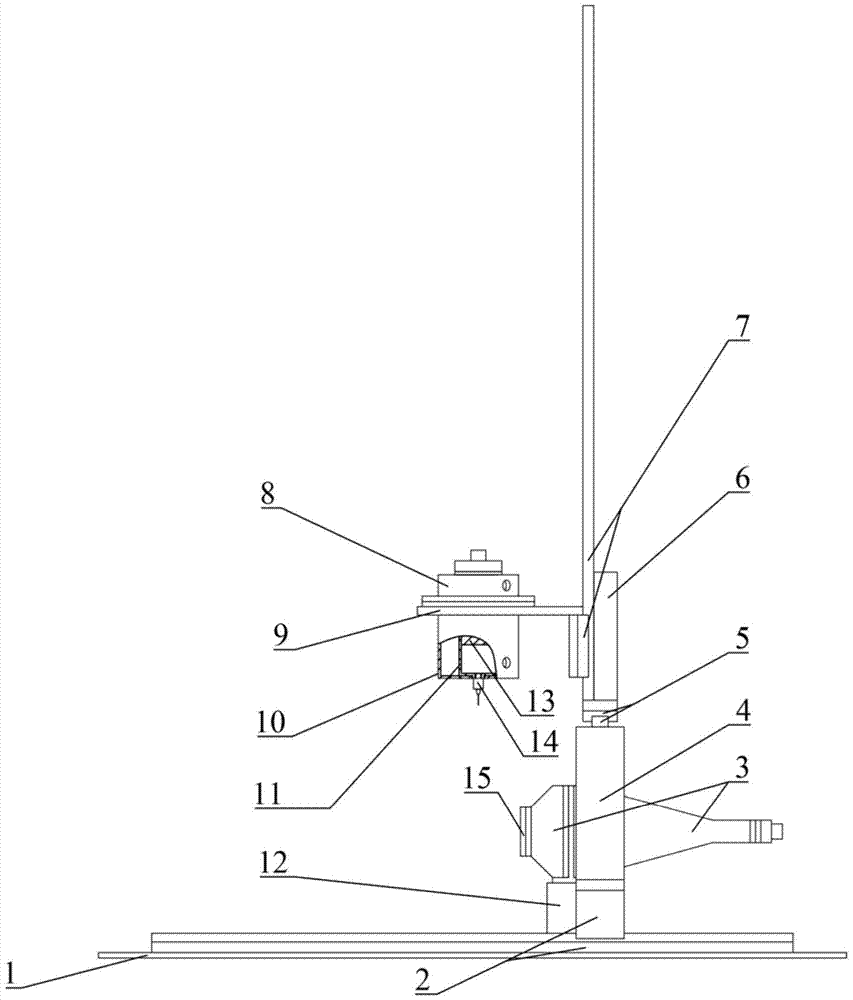

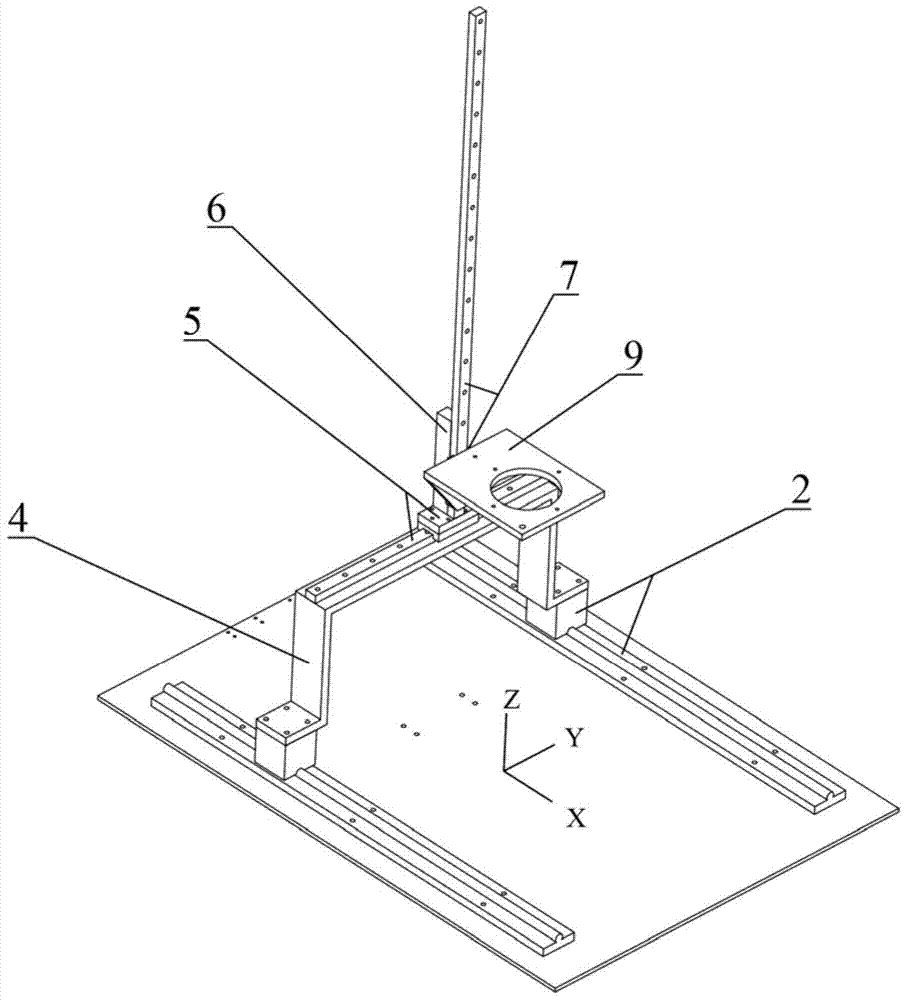

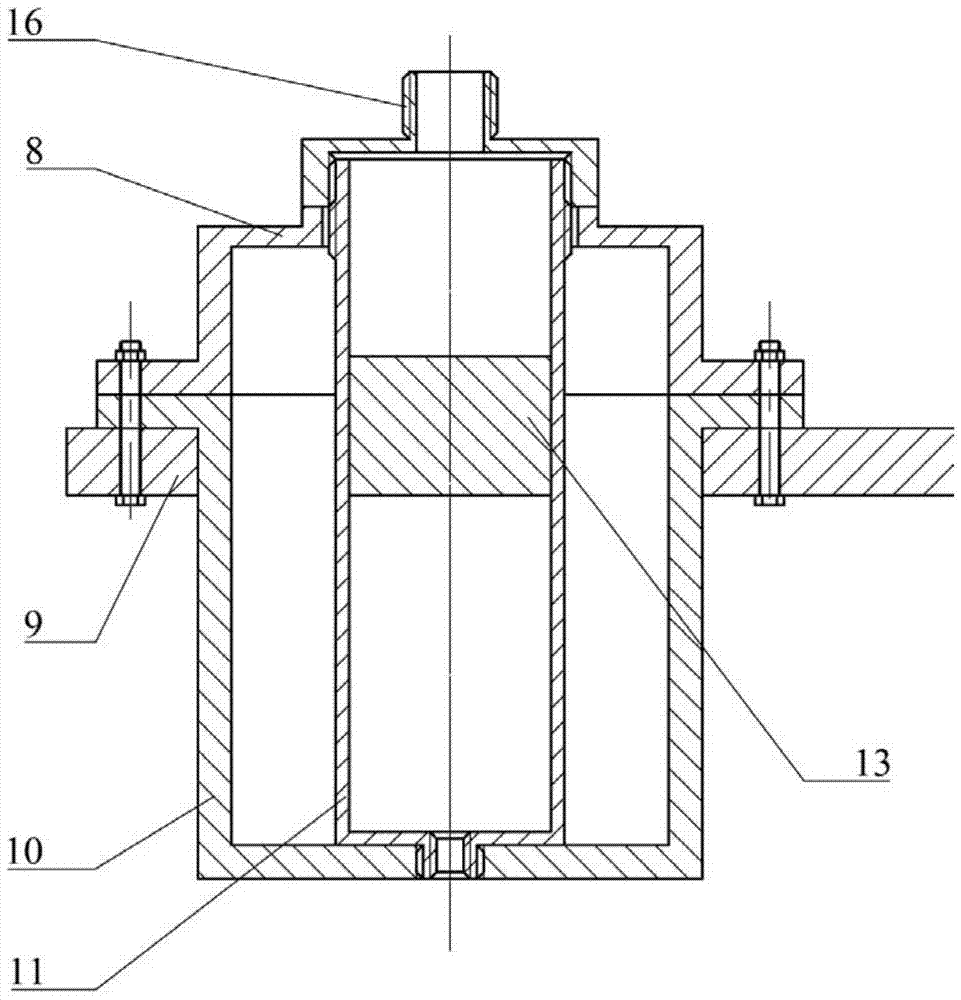

[0018] combine Figure 1 to Figure 5 :

[0019] A gel propellant single droplet secondary crushing experimental device of the present invention includes a bracket system, a droplet generator and a nozzle mechanism, wherein the bracket system includes a bottom plate 1, a lower bracket 4, a vertical bracket 6 and a droplet generator The support 9, the lower support 4 and the bottom plate 1 are slidably matched in the horizontal direction, the vertical support 6 is slidably matched with the lower support 4 in the horizontal direction, and the sliding direction is perpendicular to the sliding direction between the lower support 4 and the bottom plate 1, and the liquid droplets The generator bracket 9 is slidably matched with the vertical bracket 6 in the vertical direction, and its sliding direction is perpendicular to the sliding direction between the lower bracket 4 and the bottom plate 1 and the sliding direction between the vertical bracket 6 and the lower bracket 4; The gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com