Internal expansion type block molding device and method

A molding device and internal expansion technology, applied in ceramic molding cores, ceramic molding mandrels, etc., can solve the problems of insufficient promotion, equipment reliability defects, etc., and achieve low production costs, prolong equipment maintenance cycles, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

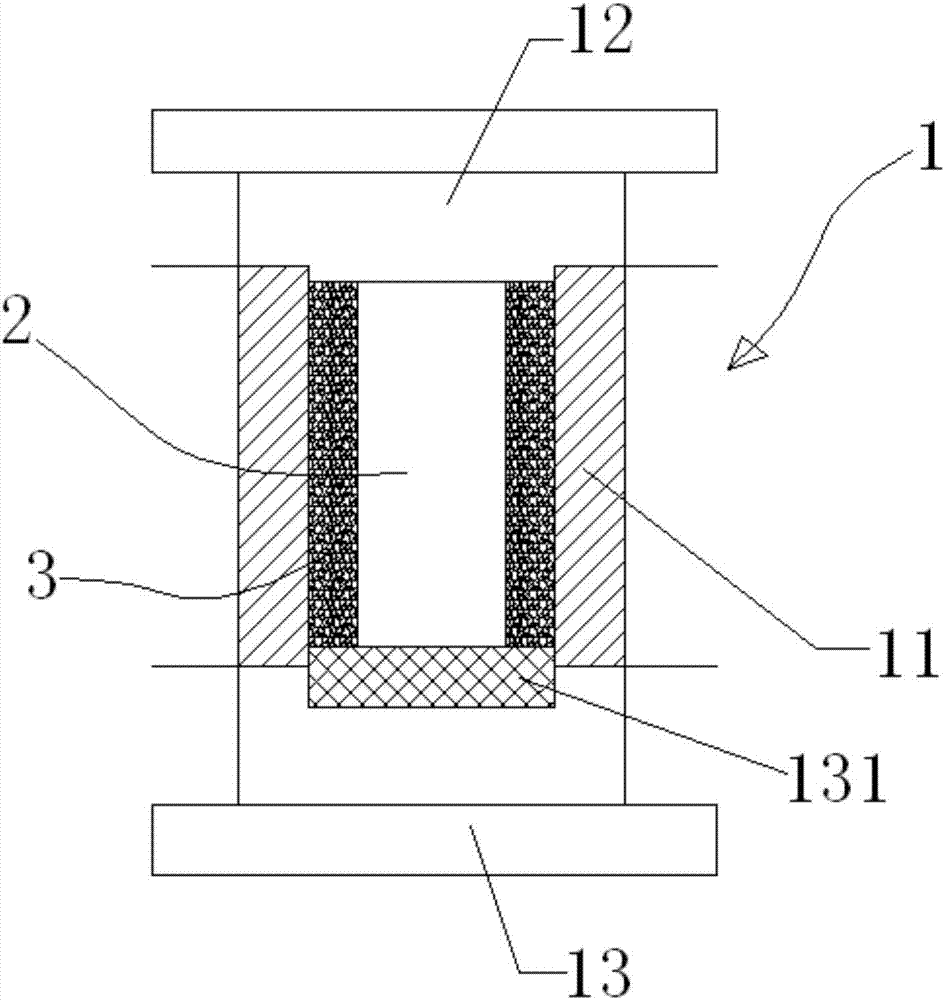

[0024] Example 1, such as figure 1 As shown, an internal expansion block forming device includes a mold 1 having at least one closed space and at least one mold core 2 that can expand to the surroundings in the middle of the closed space, and the mold core and the mold An annular material space is formed between them, and the mold core compacts the material 3 in the annular material space under the action of expansion force; wherein, the mold includes a mold frame 11, an upper mold 12 and a lower mold 13, and the mold core The mold frame is hollow cylindrical with upper and lower openings, the lower mold can move up and down and close the lower opening of the mold frame when forming blocks or press into the mold frame to a certain depth, the upper mold can move up and down and When forming blocks, the upper opening of the mold frame is closed or pressed into the mold frame to a certain depth; the lower mold is formed with an ejector plate 131 that can move up and down, and the...

Embodiment 2

[0030] Embodiment 2, this embodiment 2 has most of the technical features of embodiment 1, the difference is that the mold core of the device is a special ceramic with electricity expansion characteristics, and by electrifying the special ceramic, it will expand to the surrounding Material compaction in the annular material space.

[0031] In this way, when working, the upper mold goes up to the highest position, the lower mold is at the feeding position (closes the lower opening of the mold frame), and a specified amount of material is added to the mold frame, and then the upper mold goes down and pre-presses into the mold frame to a certain depth. , the lower die is pre-pressed into the mold frame to a certain height at the same time or step by step. After the height of the hollow block (brick) is determined, the upper and lower dies are fixed; The material in the space is pressed against the surrounding mold frame. When the mold core expands to the predetermined pressure, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com