Metal powder 3D forming method through multi-nozzle collaborative control

A technology of metal powder and collaborative control, applied in the field of 3D printing technology, can solve the problems of only making conceptual models, not being able to make functional parts, and low strength of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

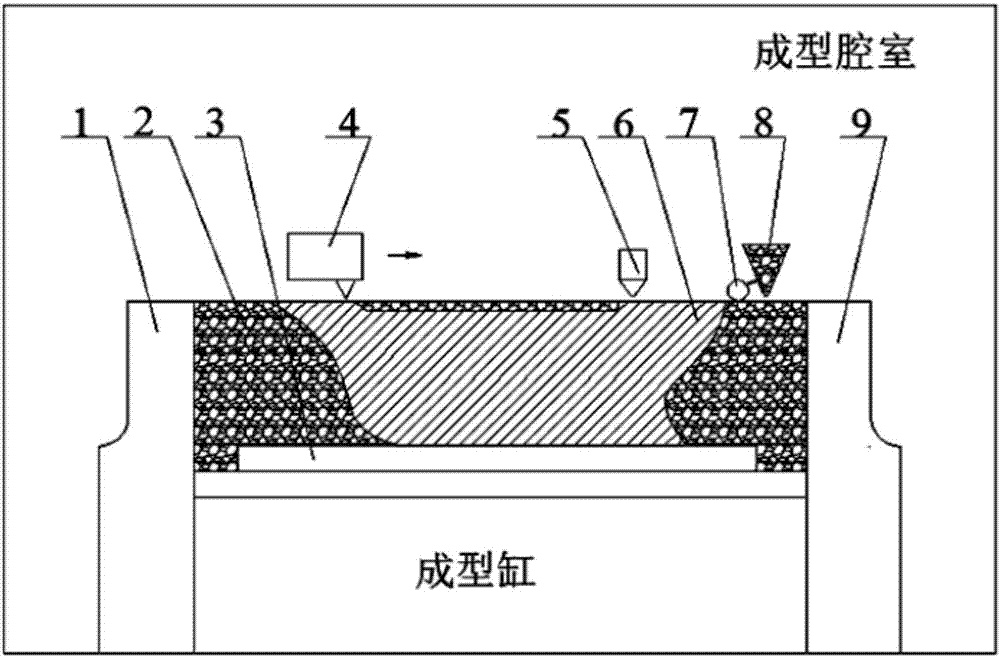

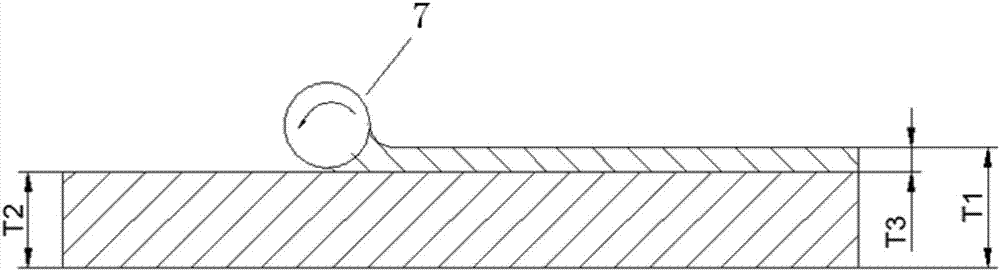

[0041] Combined below as Figures 1 to 9 The present invention is described in further detail with specific embodiments.

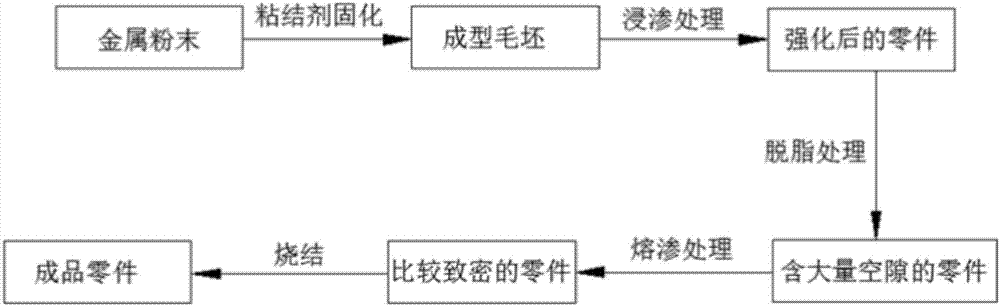

[0042] Such as figure 1As shown, the early stage of the process is bonded molding, and the metal powder in the molding chamber is bonded and formed by spraying the binder to obtain a metal part blank with a complex shape and structure. Then, in order to ensure that the part blank has a certain strength and maintain structural integrity, the part blank is impregnated before the degreasing treatment. Then, the binder inside the part blank is removed by solvent degreasing, catalytic degreasing, thermal degreasing, etc., and a large number of voids are generated in the part after the binder is removed, and then the void inside the part is filled by infiltration process, infiltration There are still some gaps inside the processed parts, and the metal powder particles are not well combined, so the parts are placed in a vacuum sintering furnace for sintering to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com