Method and facility for carrying out electrostatic precipitation on municipal engineering through construction fences

A technology of electrostatic dust removal and construction enclosure, applied in the direction of separation method, electrostatic effect separation, external electrostatic separator, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

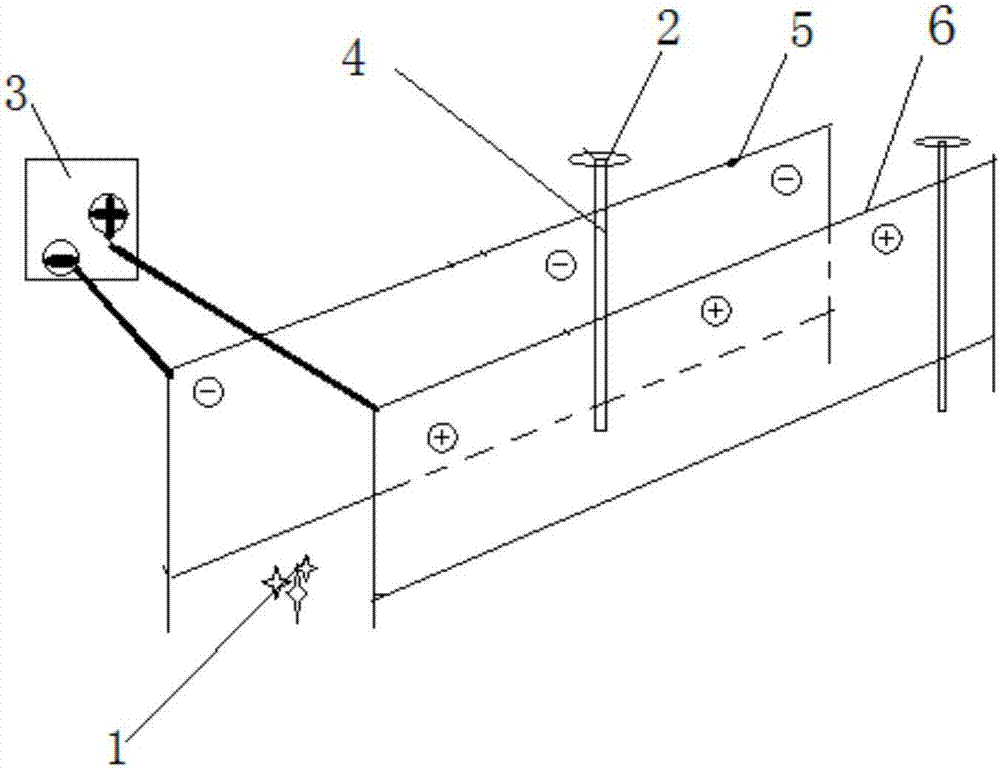

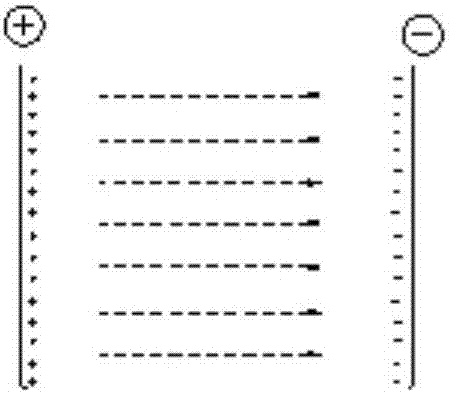

[0017] Such as figure 1 As shown, the present invention uses the construction fence to carry out electrostatic dust removal facilities for municipal engineering, including the left metal plate fence 5 and the right metal plate fence 6 of the construction site 1, wherein the left metal plate fence 5 and the right side The surface of the metal plate enclosure 6 is covered with an insulating layer, and it is ensured that the left metal plate enclosure 5 and the right metal plate enclosure 6 cannot have conductive objects conducting each other; it also includes a low-voltage DC safety power supply 3 and a low-voltage DC safety power supply 3 The positive and negative poles are respectively connected to the left metal plate enclosure 5 and the right metal plate enclosure 6; , and the water pipe 4 is communicated with the fire hydrant or the city water pipe.

[0018] When the present invention is implemented, at first the surface of the left metal plate enclosure 5 and the right si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com