Efficient distillation production device of turpentine oil

A production device and technology for turpentine oil, applied in the field of rosin processing, can solve the problems of turpentine oil and gas efflux, vapor accumulation in distillation towers, waste, etc., and achieve the effects of increasing production speed, increasing productivity, and reducing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

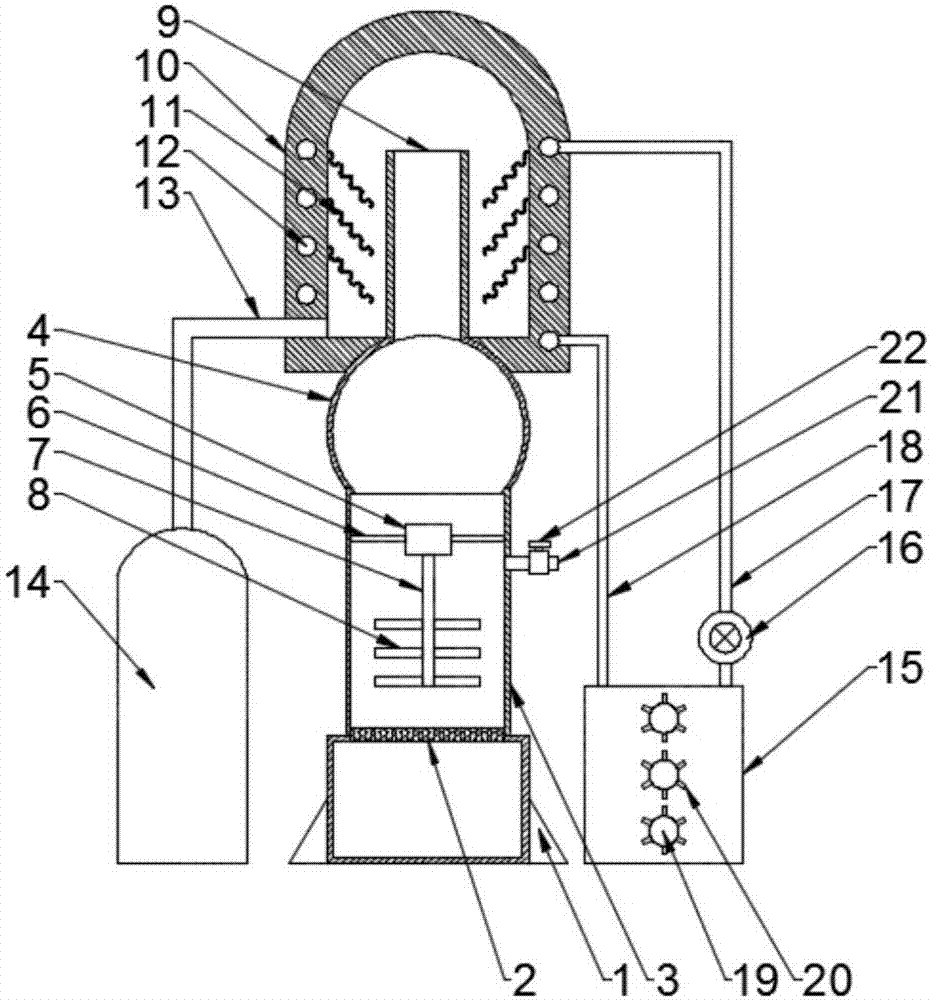

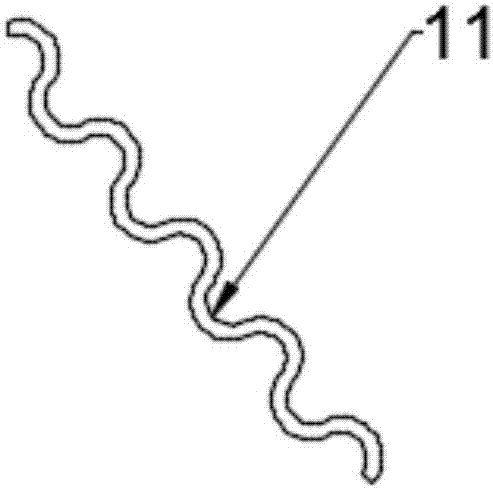

[0018] See Figure 1~2 , A high-efficiency distillation production device for turpentine, comprising a furnace base 1, an electric furnace 2, a distillation reaction tower 3, a liquefaction tank 10, an oil-water separation tower 14 and a cooler 15. The furnace base 1 is provided with an electric furnace 2. The electric furnace 2 is provided with a distillation reaction tower 3, the upper part of the inner cavity of the distillation reaction tower 3 is provided with a motor 5, the motor 5 is fixed on the inner wall of the distillation reaction tower 3 through a bracket 6, and the motor shaft of the motor 5 is fixed Connected to the stirring rod 7, a number of stirring blades 8 are uniformly arranged on the stirring rod 7, the top of the distillation reaction tower 3 is connected to the gas storage tank 4, the gas storage tank 4 is of spherical structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com