System for harmonic content correction in power electric circuit, system for electric engine control, and cooling compressor

An electric motor and refrigeration compressor technology, applied in the field of refrigeration compressors, can solve problems such as bulkiness, high energy consumption, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

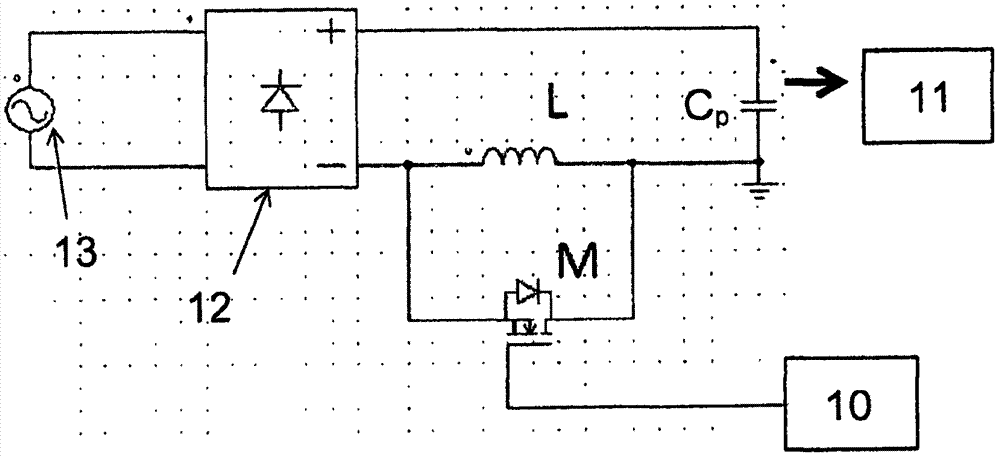

[0034] Example 1 - System for correcting harmonic content of current in a power circuit in a refrigeration compressor

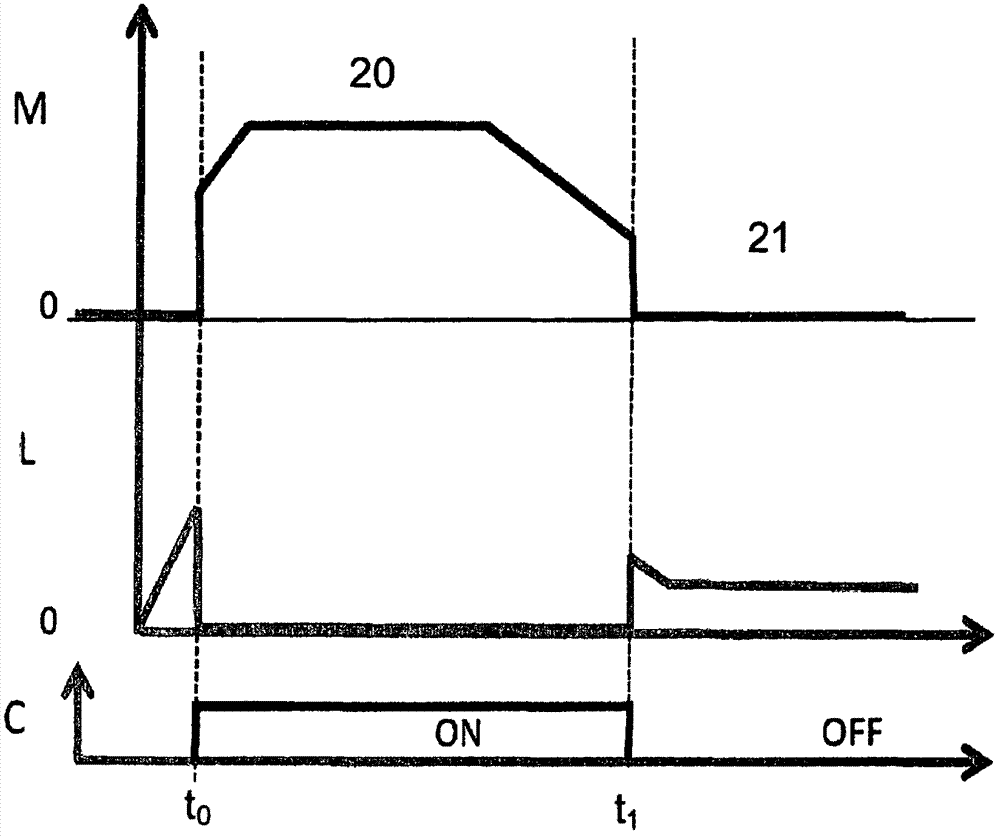

[0035] The invention provides a harmonic content correction system in a power circuit comprising an inductor (L) as a reactive element. The core of the inductor is dimensioned to be reduced, yet meeting the current requirements under normal load conditions. In this embodiment, the maximum engine operating temperature also occurs when the condition is full load or pull down (10). In this embodiment, the inductor (L) receives no current due to the actuation of the switching means (M) protecting the inductor. In this way, the inductor is sized to operate under normal conditions of the variable capacity compressor.

[0036] refer to figure 1 , it will be understood that in this embodiment of the invention, since the grinding system (12), the first reactance element (L), the second reactance element (C p ), the switchgear (M), the control system (10) and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com