Fluid soaking device for crop treatment

A crop and soaker technology, applied in the field of crop processing equipment, can solve problems such as insufficient contact between crops and soaking liquid, affect the treatment effect, and inconvenient operation, and achieve the effects of improving service life, convenient operation, and improved convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

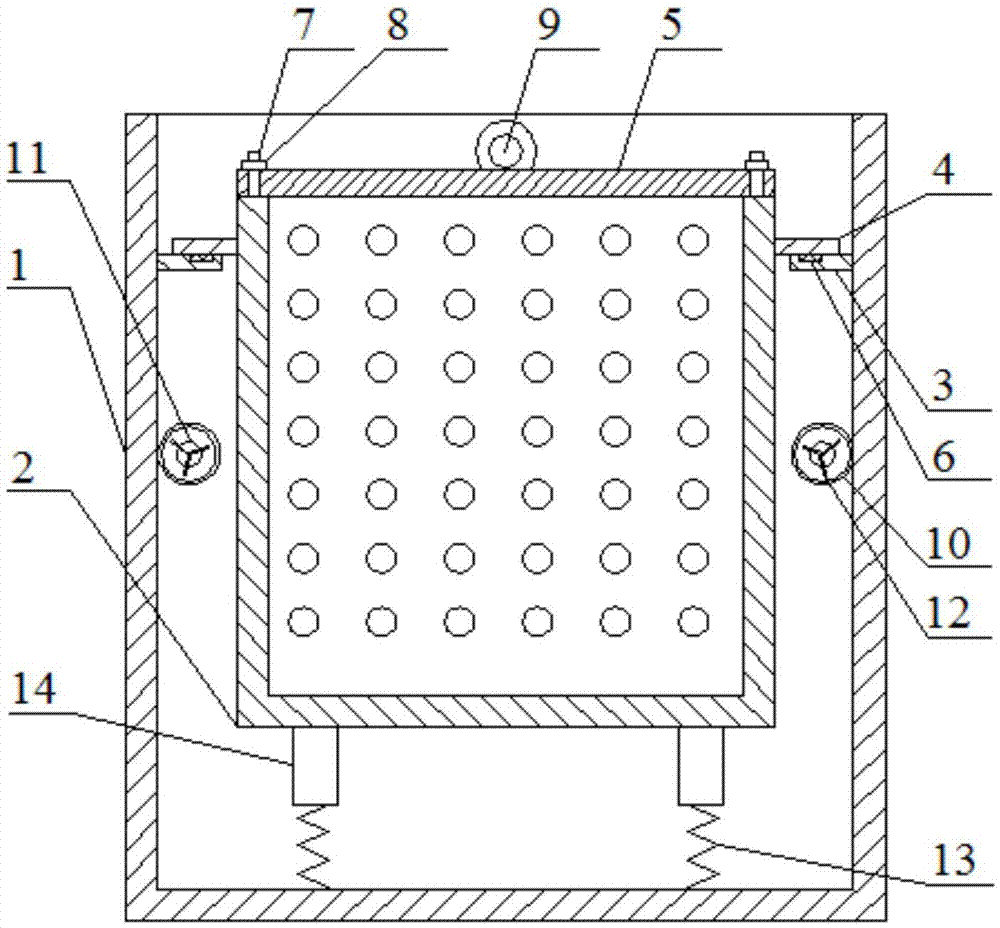

[0029] Such as figure 1 As shown, the fluid soaker for crop treatment includes an outer barrel 1, an inner barrel 2, an outer fixing ring 3, an inner fixing ring 4, and an inner barrel cover 5; the outer fixing ring 3 is fixed on the inner surface of the outer barrel 1, and the inner fixing ring 4 is fixed on the outer surface of the inner barrel 2, the inner barrel 2 is arranged in the outer barrel 1, and the inner barrel 2 is suspended on the outer fixing ring 3 through the inner fixing ring 4; the inner barrel cover 5 is arranged on the top of the inner barrel 2; the inner barrel 2 is made of a perforated plate; It includes a guide tube 10 uniformly fixed on the inner surface of the outer barrel 1, a motor 11 fixed in the guide tank 10, and an impeller 12 connected to the output shaft of the motor 11; the guide tube 10 is located below the outer fixing ring 3; A plurality of springs 13 at the bottom of the outer tub 1 and buffer posts 14 connected to the springs 13 , the bu...

Embodiment 2

[0035] Such as figure 1 As shown, on the basis of Embodiment 1, this embodiment further includes a sealing ring 6 disposed on the upper surface of the outer fixing ring 3 , and the sealing ring 6 is in contact with the lower surface of the inner fixing ring 4 .

[0036] A sealing ring 6 is provided to prevent soaking liquid from overflowing from between the outer fixing ring 3 and the inner fixing ring 4 .

Embodiment 3

[0038] Such as figure 1 As shown, on the basis of Embodiment 1, the present embodiment also includes a plurality of screw rods 7 arranged vertically on the top of the inner barrel 2, and the screw rods 7 penetrate the inner barrel cover 5; The inner barrel cover 5 is pressed on the top of the inner barrel 2.

[0039] The inner barrel cover 5 is pressed tightly on the top of the inner barrel 2 to avoid the flow of the soaking liquid and the inner barrel cover 5 is pushed away, thereby improving the working reliability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com