Device for using solid modulation to generate plasma photonic crystals

A technology of plasma and photonic crystals, applied in the field of plasma application technology and optics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

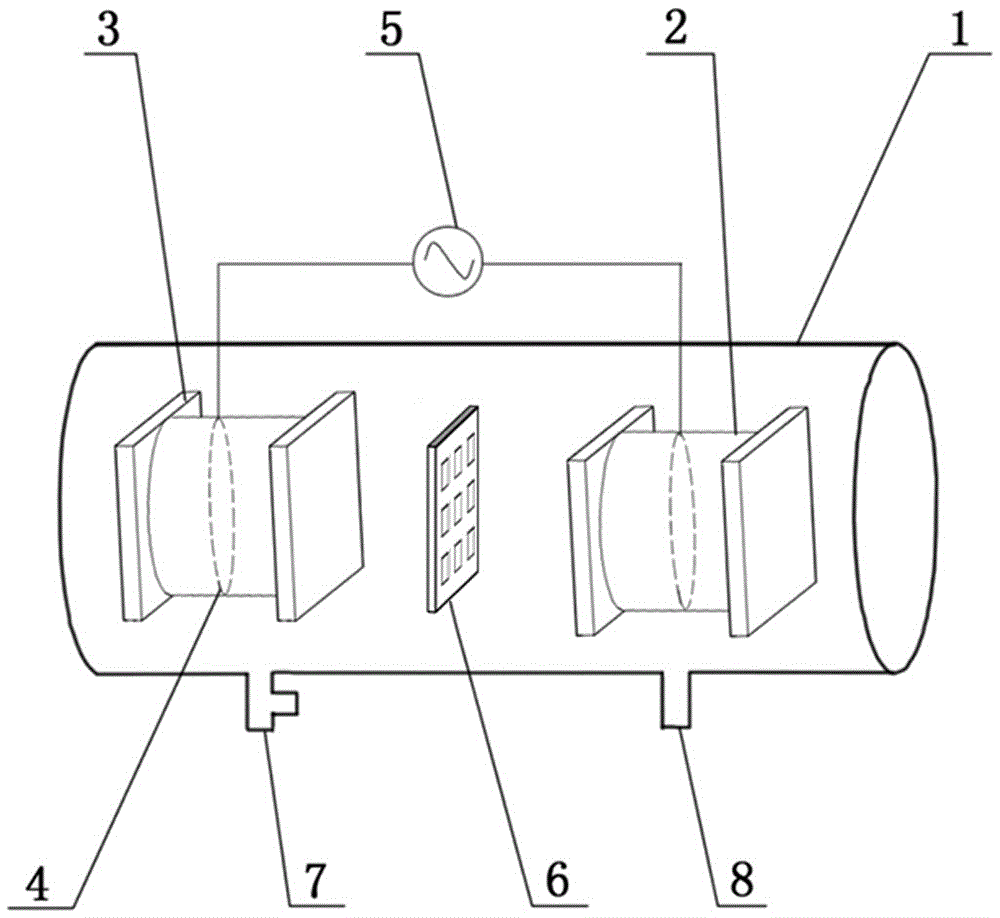

[0022] Embodiment 1, a device for generating plasmonic photonic crystals using solid state modulation.

[0023] Such as figure 1 As shown, the device for generating plasma photonic crystals provided by the present invention using solid modulation is specifically: two airtight dielectric containers are symmetrically arranged in a horizontal cylindrical vacuum reaction chamber 1, and water is injected into the airtight dielectric container. A water electrode 2 with two polar plates facing each other is formed. The two water electrodes 2 are electrically connected with the plasma generating power source 5 outside the vacuum reaction chamber 1 . In this embodiment, the water electrode 2 is made of a plexiglass tube sealed by glass baffles 3 at both ends, the plexiglass tube is filled with water, and a copper ring 4 is set in the plexiglass tube. The two copper rings 4 are respectively electrically connected to the positive pole and the negative pole of the plasma generation powe...

Embodiment 2

[0030] combine figure 1 and figure 2 , a vacuum reaction chamber 1 is set, an air inlet 7 and an air outlet 8 are opened on the wall of the vacuum reaction chamber 1, and two water electrodes 2 opposite to each other are installed in the vacuum reaction chamber 1. The water electrode 2 is composed of a plexiglass tube sealed with glass baffles 3 on both sides and filled with water, and a built-in copper ring 4 is electrically connected to the plasma generating power supply 5 outside the vacuum reaction chamber 1 .

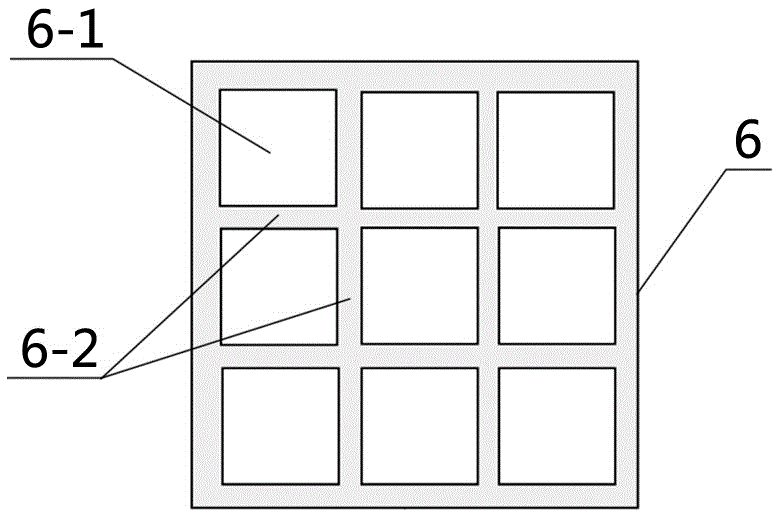

[0031] A solid frame 6 with a thickness of 2mm is arranged between the two water electrodes 2, the solid frame 6 is an acrylic plate, the plane where it is located is perpendicular to the axes of the two water electrodes 2, and the two sides are close to the two water electrodes 2 end face. Nine square through holes 6 - 1 with equal size and side length of 8 mm are opened in the inner area of the solid frame 6 , and the nine square through holes 6 - 1 are arra...

Embodiment 3

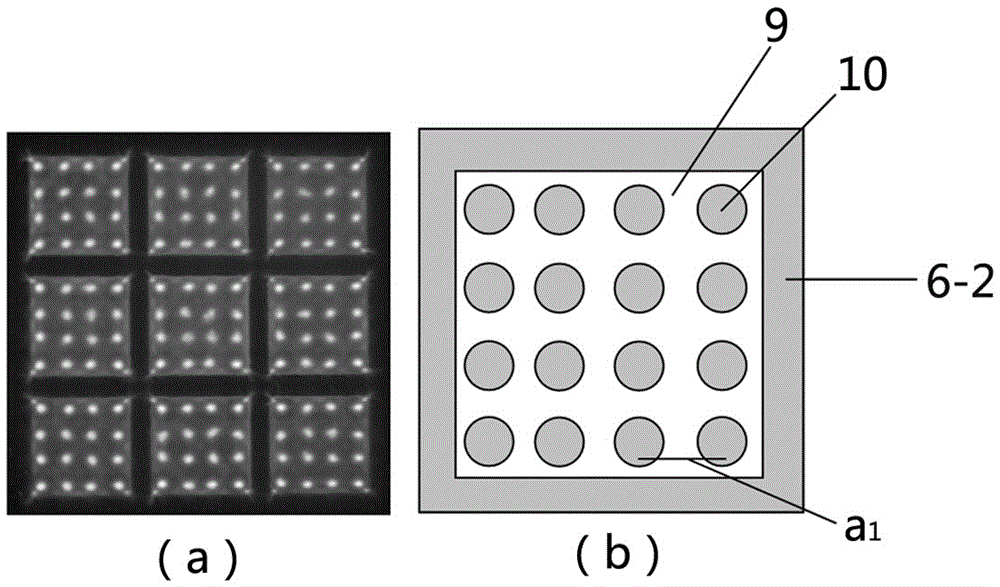

[0037] Compared with Embodiment 2, this embodiment differs in that: discharge gas pressure P=0.15atm, voltage amplitude U=3.2kV.

[0038] see Figure 5 , the present embodiment is produced by solid (solid edge 6-2 with a width of 2mm), gas (that is, the gas in the second undischarged region 12) and a lattice constant of а 2 The photo of the solid modulated plasmonic photonic crystal formed by the periodic arrangement of the quadrilateral second plasma 13 (taken by a common camera) as Figure 5 (a), Figure 5 The partial schematic diagram of a cycle in (a) is given by Figure 5 (b) shown. Figure 5 The gas shown in (b) (that is, the gas in the second undischarged region 12), the second plasma 13, and the solid edge 6-2 have different refractive indices, wherein the refractive index of the gas is 1; the second plasma 13 The refractive index of the solid edge 6-2 is less than 1; the refractive index of the solid edge 6-2 is between 1.2 and 1.4. Therefore, this embodiment als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com