Simulation test device for debris flow and test method

A technology for simulating test and debris flow, applied in soil material testing, material inspection products, etc., can solve problems such as inability to carry out continuous experiments, and achieve the effect of facilitating observation and collection of experimental data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1-debris flow simulation test method:

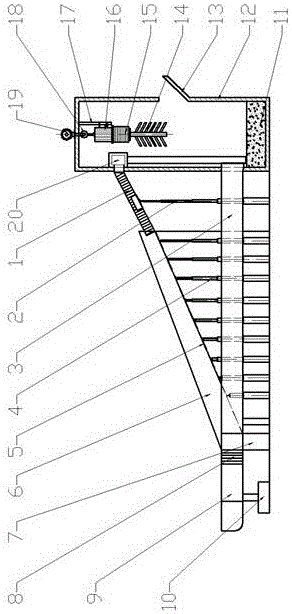

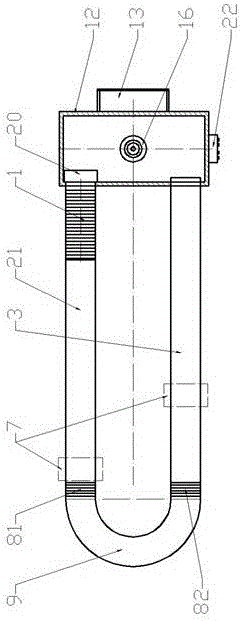

[0044] Add the debris flow mixture 11 into the bucket 12 through the feed port 13, operate the control panel 22, start the stirring system, descend and stir the mixture 11, and after making it uniform, the stirring system is raised by operating the control panel 22, and then through the control panel 22 Start the turbo pump 20, transport the debris flow mixture to the designated height to start the experiment, and collect the experimental data and patterns. Stirring system and turbo pump 20 can choose to work simultaneously or can choose to work alone, and the two cooperate with each other to work independently. During the experiment, the debris flow mixture 11 continuously enters the bucket 12 through the horizontal chute 3 to be recycled.

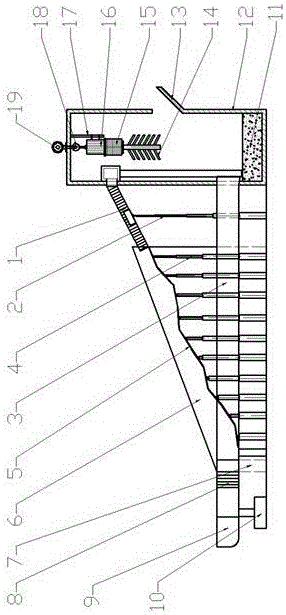

[0045] image 3 It shows a schematic diagram of a debris flow simulation test device in the adjustment state of the inclined chute. Turning the stud bolt 28 can realize the direc...

Embodiment 2

[0047] Embodiment 2-debris flow simulation test method:

[0048] Figure 4 Shows a state diagram in which the inclined chute is in the horizontal plane in the debris flow simulation test device, changing the height of the hydraulic jack group and the length of the slope adjustment screw 28 can reach a position close to the horizontal position, so as to be used for studying the horizontal position. natural flow under action. During the experiment, the debris flow mixture 11 continuously enters the bucket 12 through the horizontal chute 3 to be recycled.

Embodiment 3

[0049] Embodiment 3-barrier test:

[0050] When there is no need to study the impact force and information collection of the debris flow, the connection cover 24 and the connection cover 25 are all in a horizontal position, and the debris flow flows through it; Debris flow interception, simulation of the impact force during the flow of debris flow, observation and extraction of experimental data and collection of patterns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com