Thin film thermal shrinkage measuring method and measuring device

A technology of thermal shrinkage rate and measurement method, which can be used in measuring devices, material thermal analysis, instruments, etc. It can solve the problems of inaccurate length measurement and film heating deformation, and achieve the effect of accurate thermal shrinkage rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] method embodiment

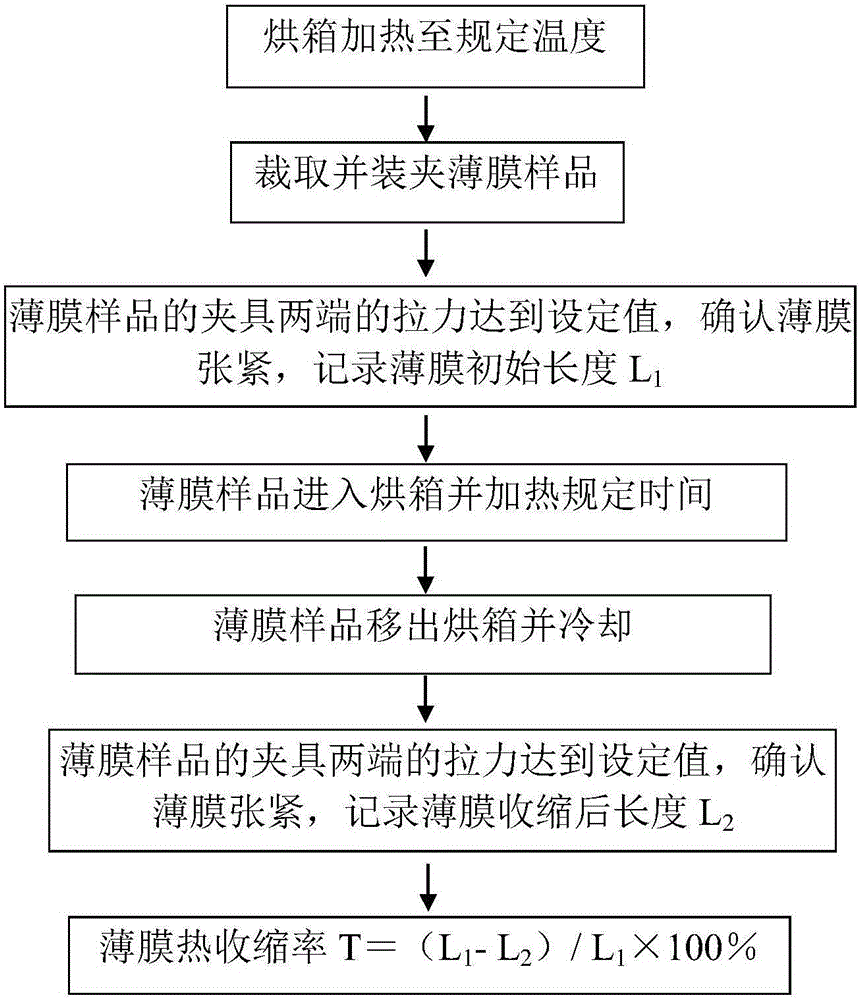

[0026] like figure 1 As shown, the measurement method of film heat shrinkage adopts the following steps:

[0027] (1) Turn on the oven and prepare for the test when the temperature of the oven rises to the set value and stabilizes for more than 30 minutes;

[0028] (2) Cut and use a clamp to clamp the film sample, and cut the cigarette film into a certain size, 100mm-300mm in length and 5mm-10mm in width. Specifically, the cigarette film can be cut into a side length of about 120mm in width 5mm rectangle (the sample test length is 100mm, but considering the length of the clamps on both sides, the actual length of the sample cut is about 120mm);

[0029] (3) The tensile force at the two ends of the clamps of the film sample reaches the set value of the tensile force, so that the film sample is in a moderately tensioned state, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com