Intellectualized bore testing device

A measuring device and dimple technology, applied in measuring devices, instruments, etc., can solve the problems of long time-consuming, labor-intensive, labor-intensive, labor-intensive and other problems of measurement process, achieve simple structure, low experience requirements, and improve the effect of precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The present invention will be further described below in conjunction with the drawings and embodiments:

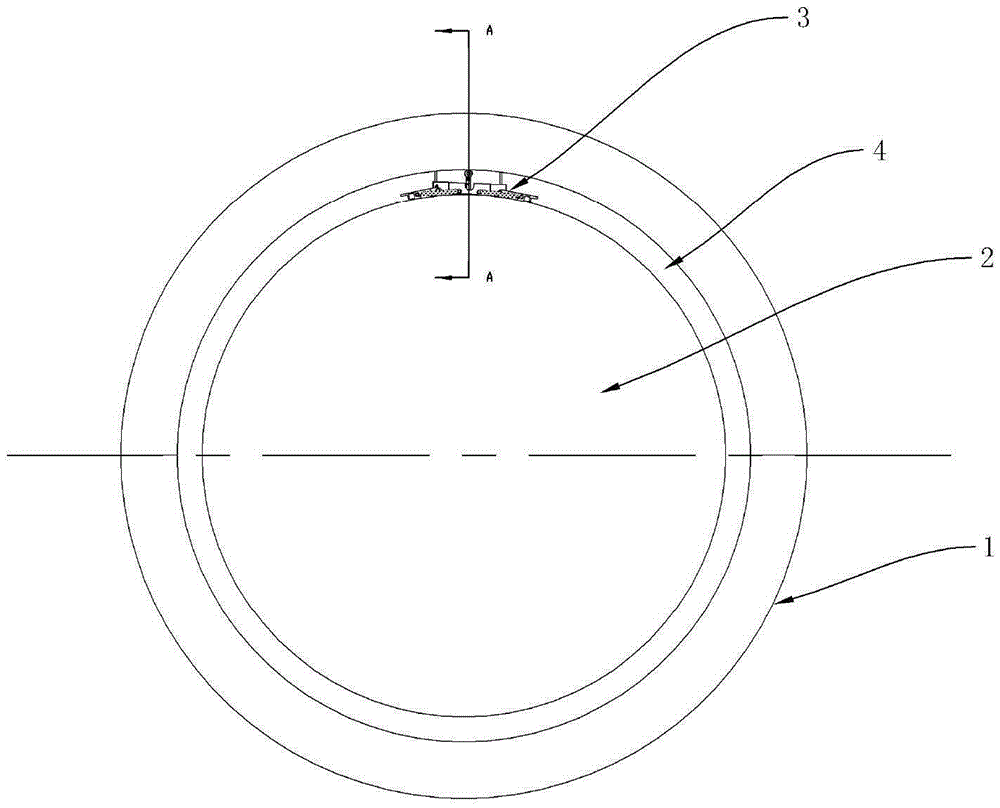

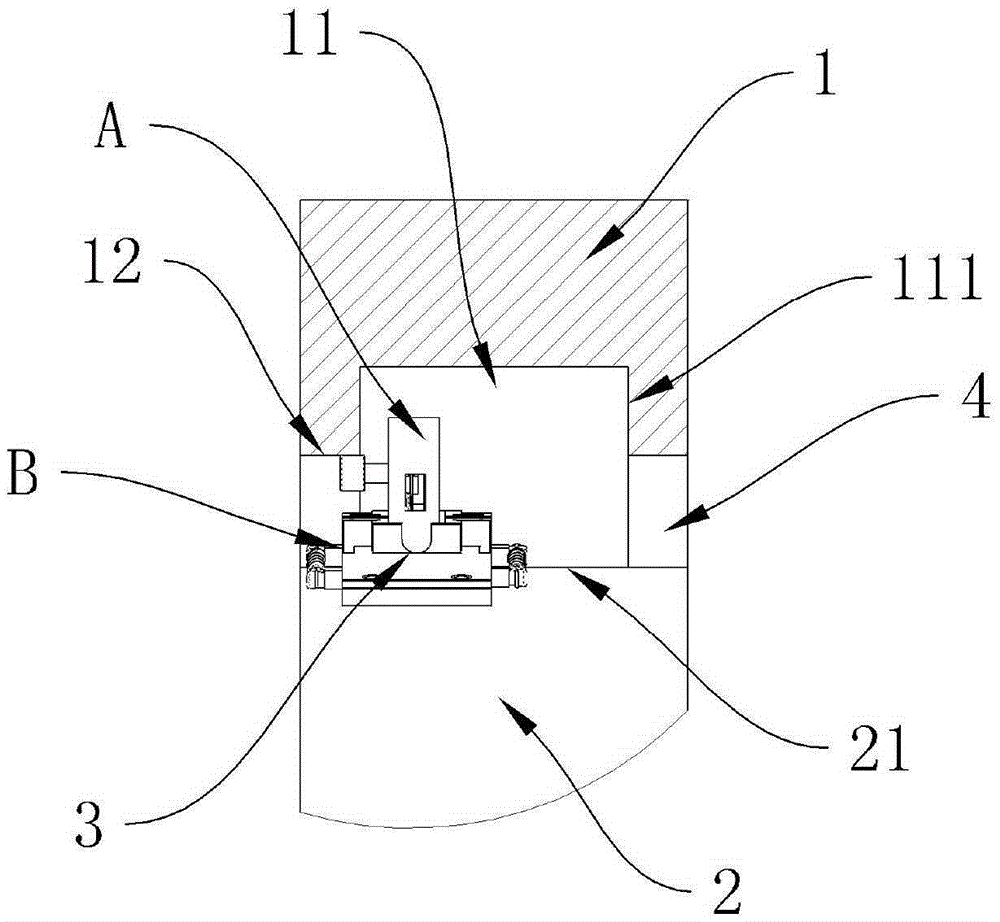

[0088] See Figure 1 to Figure 22 , An intelligent dimple measuring device, which determines whether the rotor 2 is coaxial with the dimple 1 by measuring the gap 4 between the steam turbine rotor 2 and the dimple 1 (that is, the center coincides).

[0089] In order to adapt to the measurement of full cylinder and half cylinder, the dimple measuring device is divided into a full cylinder measuring device 3 and a half cylinder measuring device 5. The half-cylinder measuring device 5 is used for figure 1 The middle dimple 1 has only a semicircle or the dimple is not a complete circle.

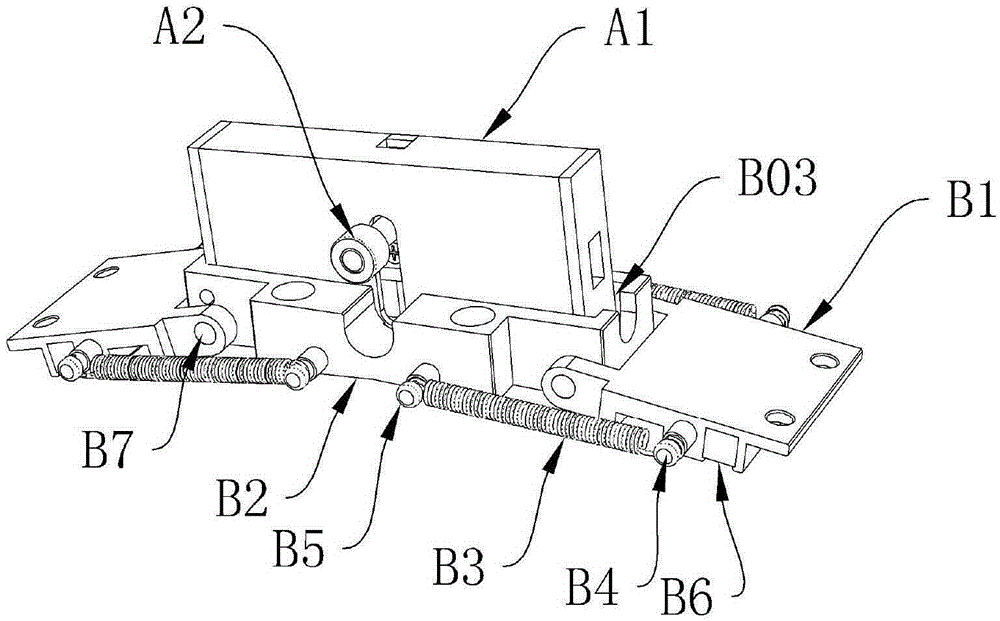

[0090] The dimple measuring device includes a chip and a carriage. The chips can be divided into a full-cylinder chip A and a half-cylinder chip C; the carriage can be divided into a full-cylinder carriage B and a half-cylinder carriage D;

[0091] See figure 2 For full-cylinder measurement, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com