Air drying equipment for preprocessing of linen and cotton

A primary processing and equipment technology, which is applied in the field of air-drying equipment for primary processing of hemp and cotton, can solve problems such as accidents and weather factors, and achieve fast air-drying speed, improved air-drying effect, and good air-drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

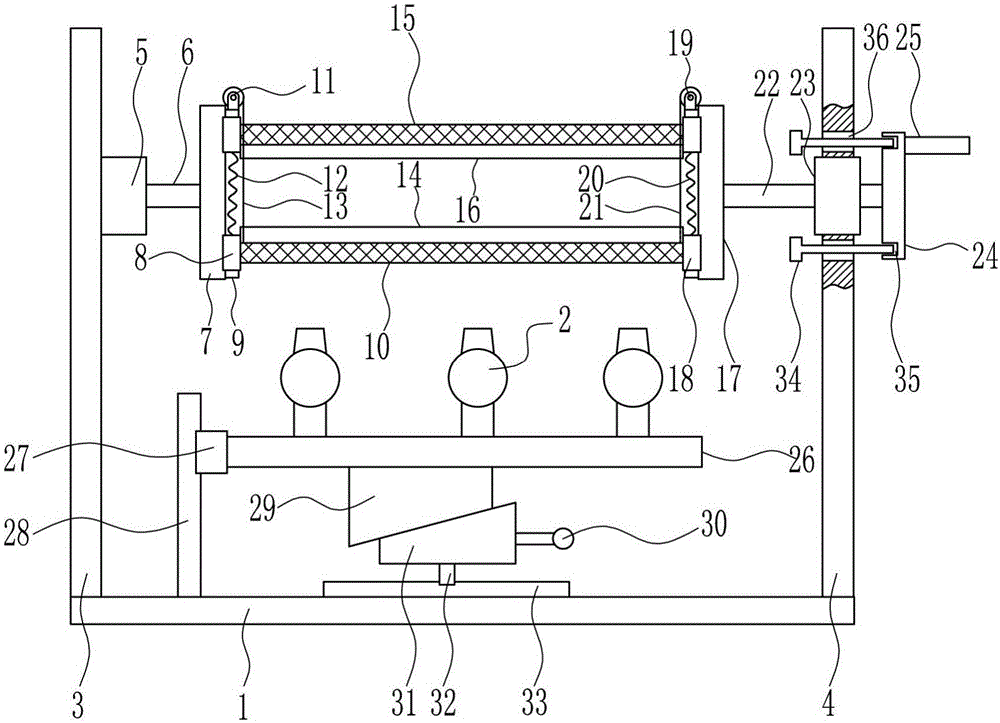

[0028] A kind of air-drying equipment for primary processing of hemp cotton, such as Figure 1-4As shown, it includes a bottom plate 1, a hot air blower 2, a left frame 3, a right frame 4, a bearing seat 5, a first rotating shaft 6, a first slide rail 7, a first slider 8, a fixed block 9, and a first mesh plate 10 , the first electric reel 11, the first spring 12, the first pull wire 13, the first baffle plate 14, the second mesh plate 15, the second baffle plate 16, the second slide rail 17, the second slider 18, the first Two electric reels 19, the second spring 20, the second backguy 21, the second rotating shaft 22, the first bearing 23, the rotating disk 24 and the rocking handle 25, the middle of the base plate 1 top is evenly provided with a hot air blower 2, the left side of the base plate 1 top The left frame 3 is welded, the right frame 4 is welded on the top right side of the bottom plate 1, the upper part of the right side of the left frame 3 is connected with a be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com