Deep well drilling execution mechanism with drill column based on dual-speed variable-torque drill bit

A technology for actuators and drill bits, which is applied in the direction of drill bits, drilling equipment, directional drilling, etc. It can solve problems such as narrow application range, high requirements for oil cylinder technology, sealing technology, and push rod damage, and achieve good practical results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

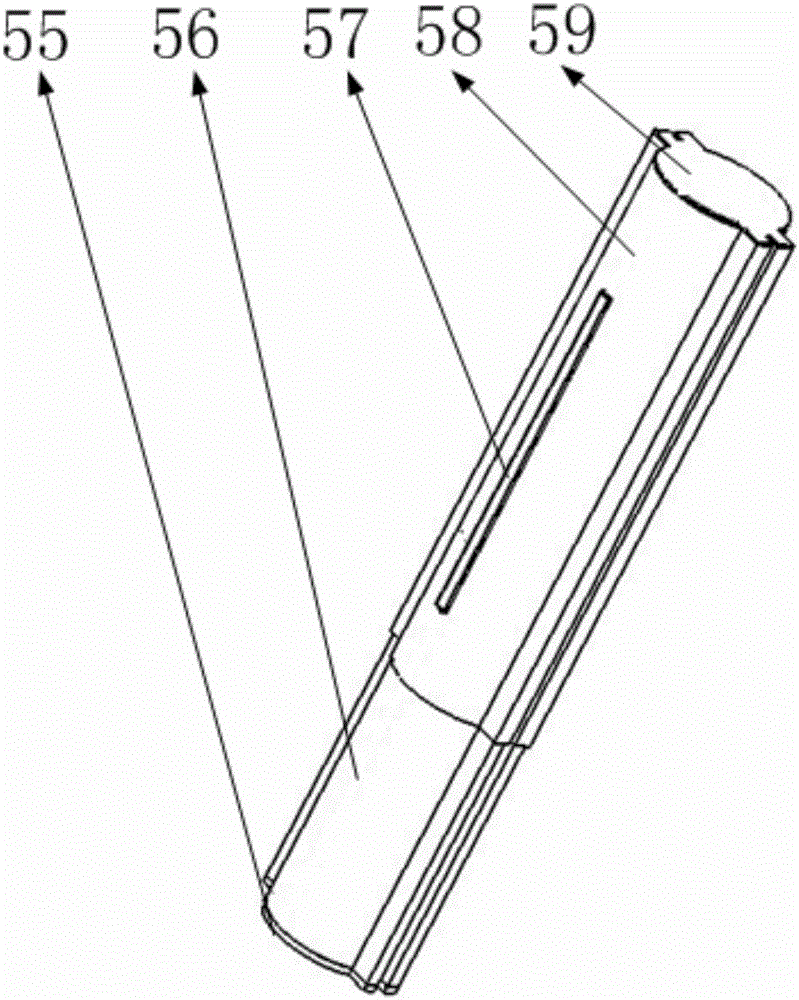

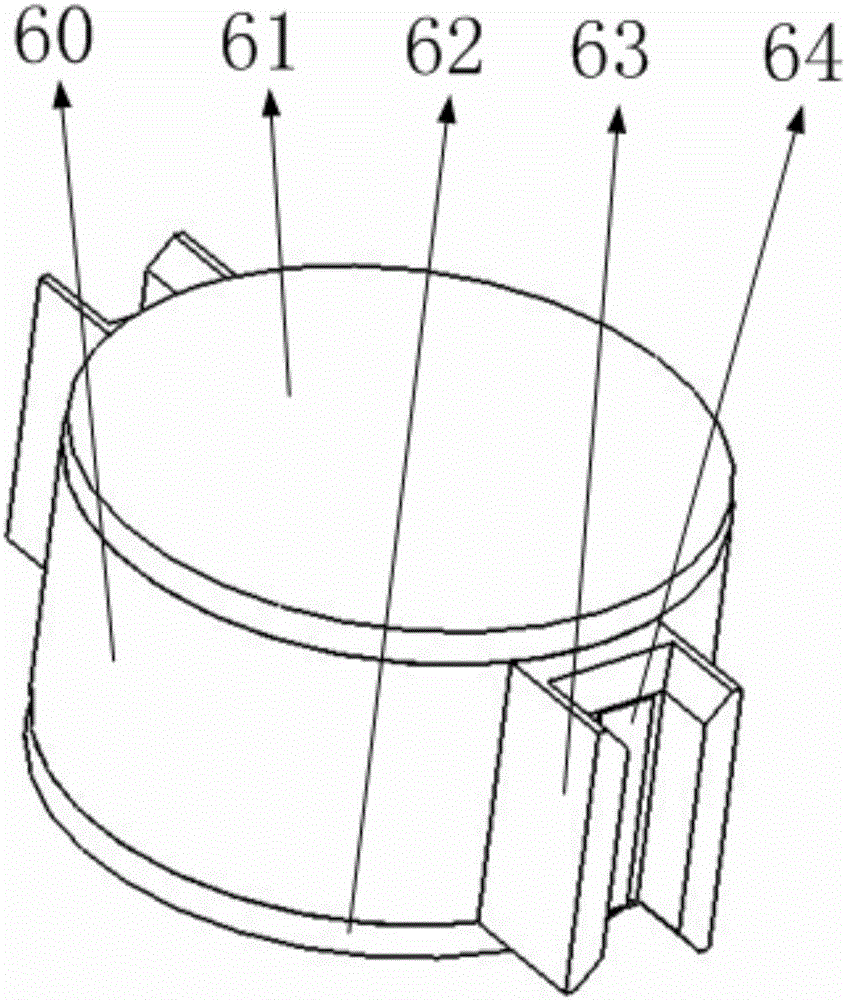

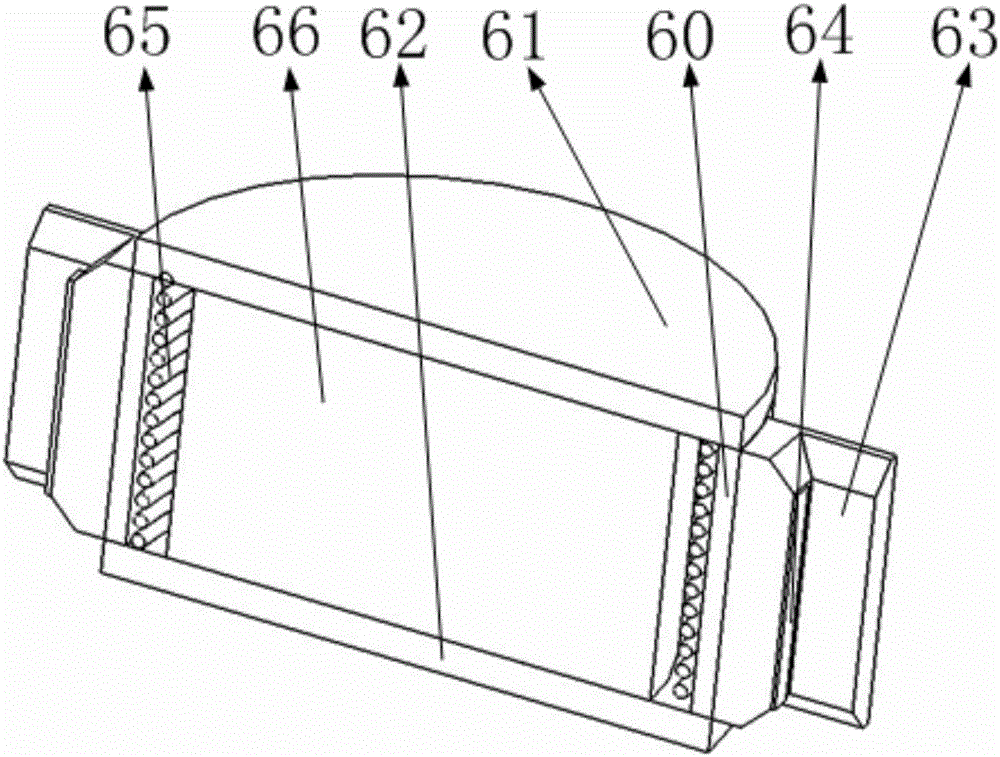

[0054] like Figure 23 , 24 As shown, it includes a drill bit drill rod, a pressure support plate, a pressure electromagnetic telescopic rod, a connecting structure, a drill bit, a positioning bracket, a second positioning mechanism, a first positioning mechanism, and a drill string. Figure 23 As shown, the drill bit is installed on the drill rod, and the drill rod is installed on the central hole of the pressure support plate through the bearing; the three pressure electromagnetic telescopic rods are evenly installed around the center hole of the pressure support plate in the circumferential direction, and the second The positioning mechanism is installed on three pressure-applying electromagnetic telescopic rods, the three positioning brackets are evenly installed on the upper side of the second positioning mechanism in the circumferential direction, and the first positioning mechanism is installed on the three positioning brackets; the drill string is connected to the dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com