Electric control springboard type rear cabin door structure

A rear door and power mechanism technology, applied in the direction of power control mechanism, wing leaf control mechanism, door leaf, etc., can solve the problems of low transmission efficiency, hydraulic oil leakage, heavy door body weight, etc., to reduce the weight of the door body, Improve the effect of poor sealing and light weight of the door body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings, but not as a limitation of the present invention.

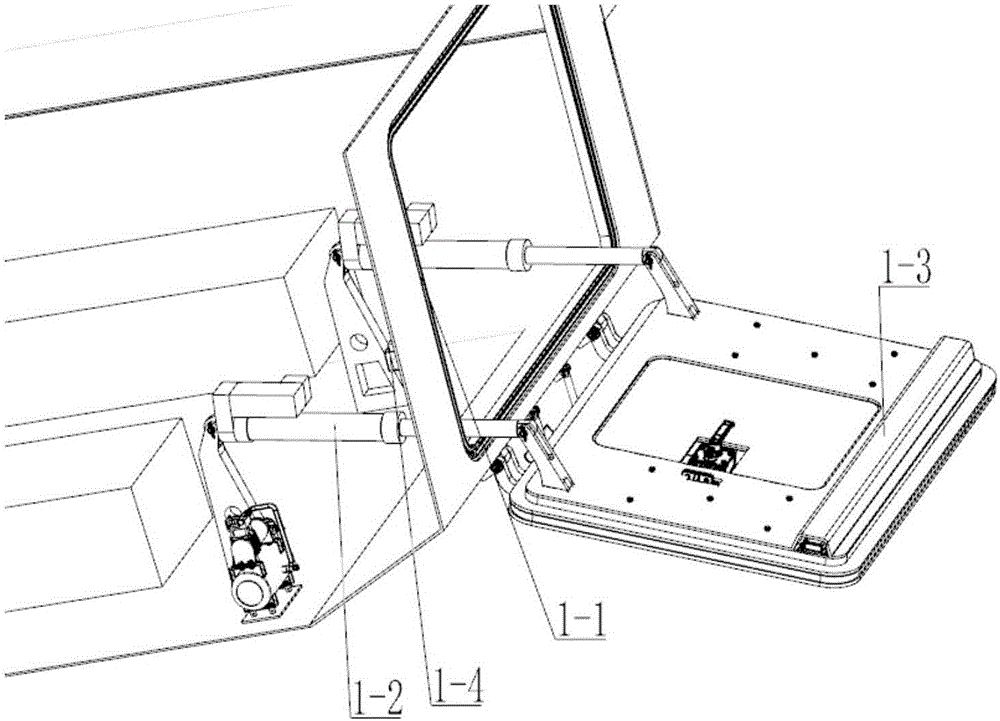

[0028] An electric control springboard type rear cabin door mechanism of the present invention has a structure such as figure 1 As shown, it includes four parts: door body and seal 1-1, power mechanism 1-2, locking mechanism 1-3 and control device 1-4. The specific structure of each part is as follows figure 2 , 3 , 4 shown.

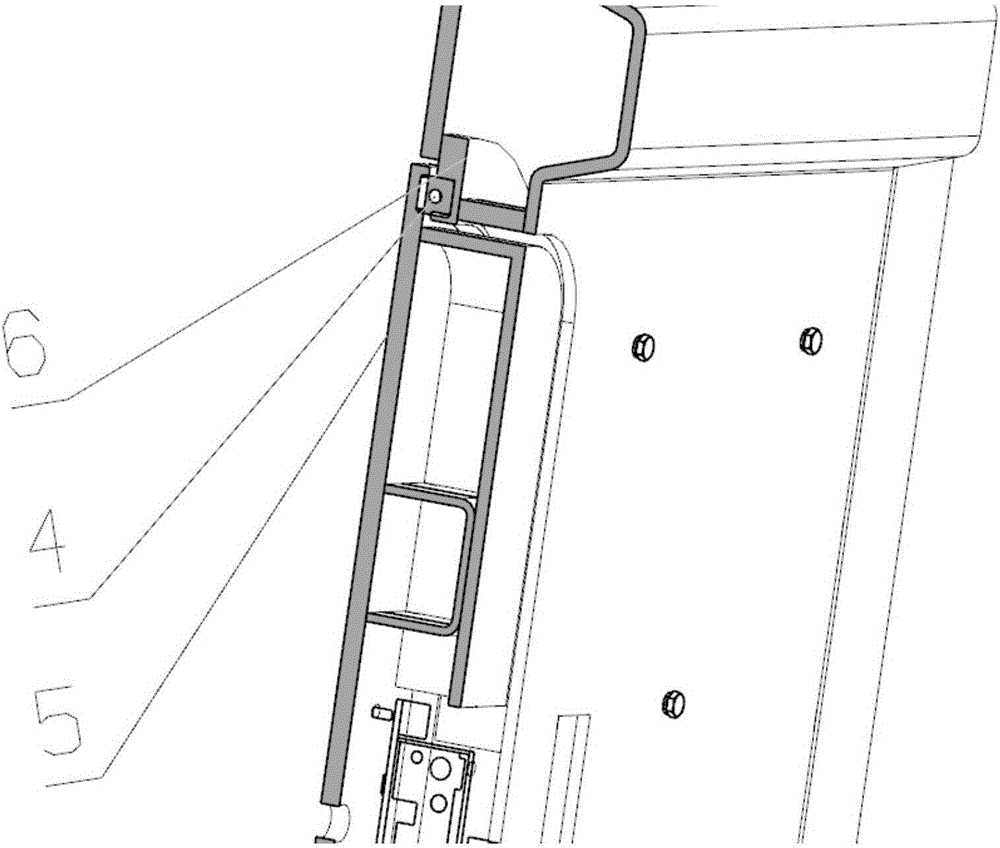

[0029] like figure 2 As shown, door body and seal 1-1, including inflatable sealing strip 1, rear hatch door body 2, rear hatch door frame 3, escape door sealing strip 4, escape door body 5, escape door frame 6, pivoting arm 7, Car body connecting block 8, rotating pin shaft 9, air pump mechanism 10;

[0030] like Figure 2-1 , 2-2, in order to meet the sealing requirements of the car body, the inflatable sealing strip 1 is installed in the groove of the rear door frame 3, and the rear do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com