Thermoplastic organic silicon polyurethane elastomer and preparation method thereof

A polyurethane elastomer and silicone technology, applied in the field of thermoplastic silicone polyurethane elastomer and its preparation, thermoplastic polyurethane elastomer, can solve the problem of poor skin affinity of TPU, poor mechanical strength, tensile strength and tear strength, and dirt resistance. , Insufficient penetration resistance, etc., to achieve the effect of smooth hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

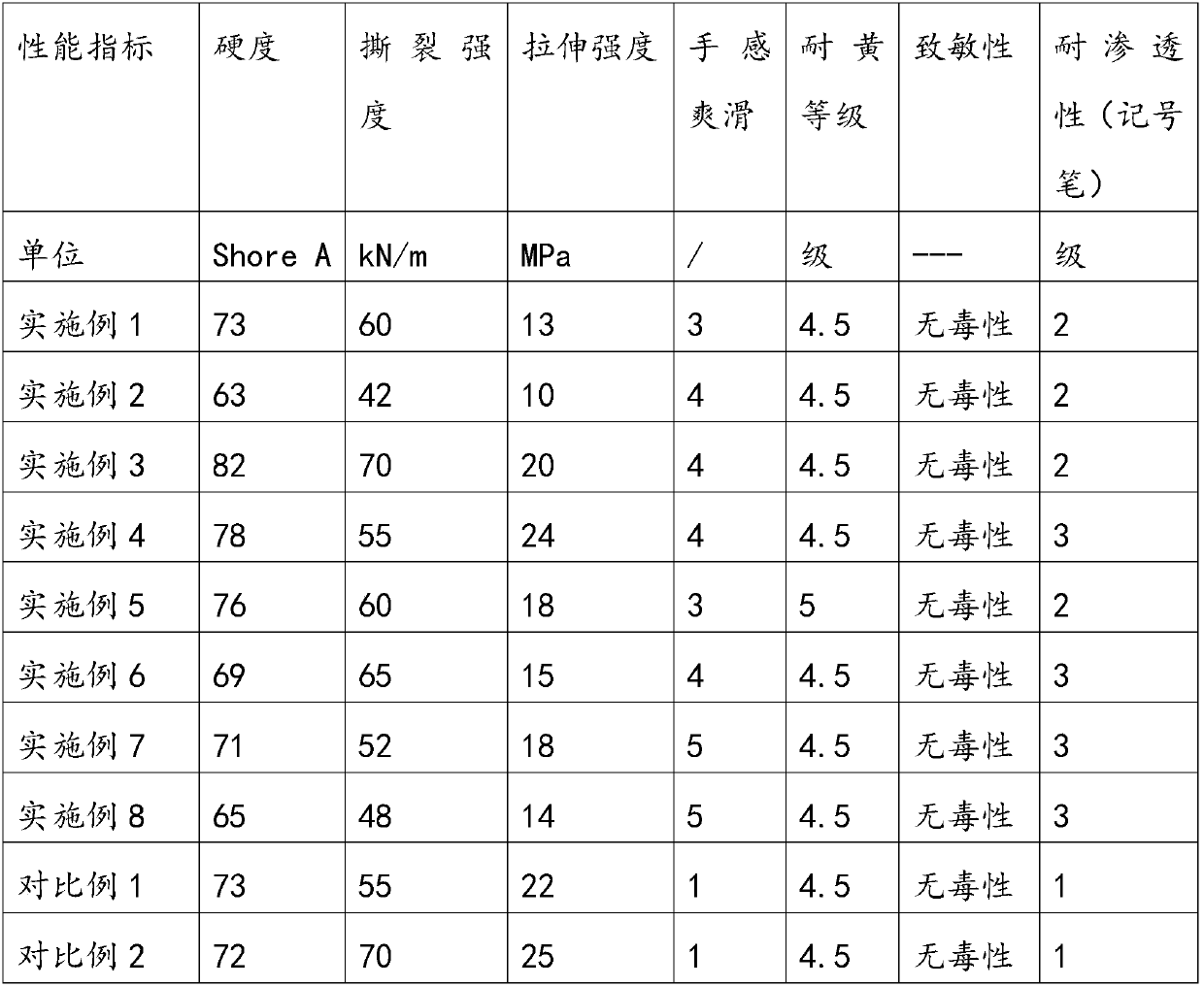

Examples

Embodiment 1

[0030] A kind of thermoplastic silicone polyurethane elastomer, its raw material composition is as follows: the polytetrahydrofuran ether glycol (PTMG) of molecular weight 2000g / mol, 57 parts; Both ends are by the organosilicon oil of PEG capping, hydroxyl value 38mg KOH / g, 15 parts ; Diphenylmethane diisocyanate (MDI), 23 parts; 1,4-butanediol, R=nNCO / nOH=1.01 in the total system, 15 parts; Antioxidant 1010, 0.6 part; light stabilizer 622, 0.5 copies, 3280.8 parts; lubricant EBO, 0.3 parts, silicone powder 0.2 parts.

[0031] The preparation method of above-mentioned thermoplastic silicone polyurethane elastomer is as follows:

[0032] 1) Add the weighed antioxidant, light stabilizer and lubricant into polytetrahydrofuran ether glycol (PTMG), heat to 100°C and stir for 2 hours to completely dissolve the additive;

[0033] 2) After that, add the heated polytetrahydrofuran ether glycol (PTMG), 1,4-butanediol, diphenylmethane diisocyanate (MDI) at 45-50°C, and silicone oil...

Embodiment 2

[0036] A kind of thermoplastic silicone polyurethane elastomer, its raw material composition is as follows: the polytetrahydrofuran ether glycol (PTMG) of molecular weight 1800g / mol, 59 parts; Both ends are by the organosilicon oil of PEG capping, hydroxyl value 55mg KOH / g, 30 parts ; Diphenylmethane diisocyanate (MDI), 32 parts; 1,4-butanediol, R=nNCO / nOH=1.01 in the total system, 20 parts; Antioxidant 1010, 0.2 parts, 1076, 0.3 parts; light stabilizer 770, 1.0 copies, 0.5 part of P; 0.5 part of lubricant EBS, 0.5 part of oleic acid amide.

[0037] The preparation method of above-mentioned thermoplastic silicone polyurethane elastomer is as follows:

[0038] 1) Add the weighed antioxidant, light stabilizer and lubricant into polytetrahydrofuran ether glycol (PTMG), heat to 100°C and stir for 2 hours to completely dissolve the additive;

[0039] 2) After that, add the heated polytetrahydrofuran ether glycol (PTMG), 1,4-butanediol, diphenylmethane diisocyanate (MDI) at ...

Embodiment 3

[0042] A kind of thermoplastic silicone polyurethane elastomer, its raw material composition is as follows: the polyoxyethylene glycol (PEG) of molecular weight 2500g / mol, 45 parts; Both ends are by the organosilicon oil of PEG capping, and hydroxyl value is 40mg KOH / g, 30 parts ; Toluene diisocyanate (TDI), 50 parts; 1,3-propanediol, R=nNCO / nOH=1.01 in the total system, 10 parts; Antioxidant 1010, 0.2 parts, 1076, 0.2 parts, 1098, 0.2 parts; light stabilizer 770, 1.5 copies, 0.5 part of P; 0.6 part of lubricant erucamide, 0.6 part of stearic acid amide.

[0043] The preparation method of above-mentioned thermoplastic silicone polyurethane elastomer is as follows:

[0044] 1) Add the weighed antioxidant, light stabilizer, and lubricant into polyethylene oxide glycol (PEG), heat to 100°C and stir for 2 hours to completely dissolve the additive;

[0045]2) Finally, add the heated polyoxyethylene glycol (PEG), 1,3-propanediol, toluene diisocyanate (TDI) at 45-50°C, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com