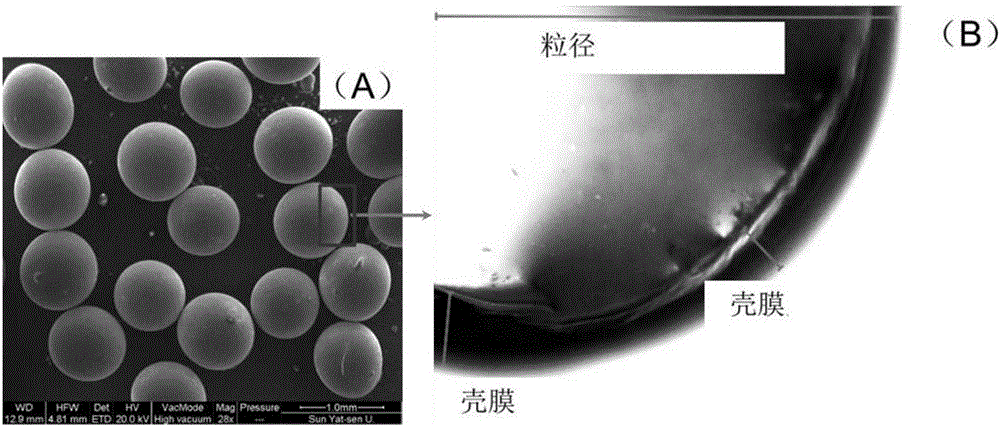

Core-shell moisturizing material, and preparation method and application thereof

A water-locking, core-shell technology, which is applied in the field of core-shell water-locking materials and their preparation, can solve the problems of inability to lock water, recover solvents in the preparation process, complex dispersants, and easy-to-dissolve water, etc. performance, improve the one-way water-locking performance, and the effect of reasonable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

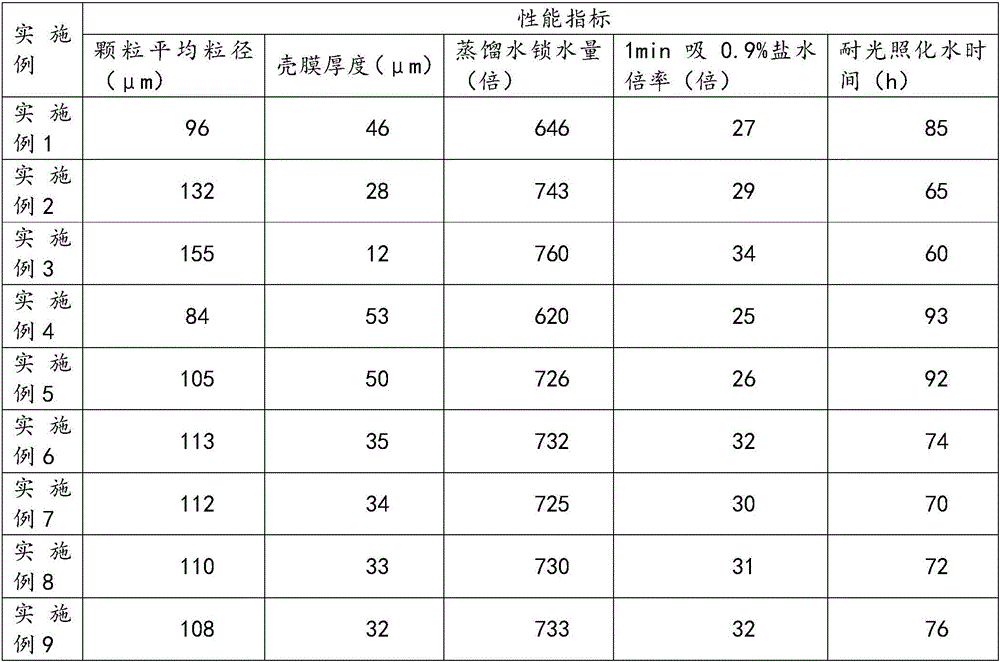

Embodiment 1

[0028] Preparation method of core-shell water-locking material:

[0029] ① Add 72.06g of acrylic acid to 38.88g of deionized water, mix well, and neutralize with 30% sodium hydroxide solution (26g of sodium hydroxide + 60.67g of deionized water) at room temperature until the neutralization degree is 65%. Then 24.02 g of hydroxyethyl acrylate were added.

[0030] ② After the neutralization solution is cooled to room temperature, add sodium alginate: 2g, tetraallyloxyethane: 0.48g, azobisisobumizole hydrochloride: 0.2g, potassium persulfate: 0.05g, carbonic acid Sodium hydrogen: 1.6g, urea: 4.8g, ethanol: 3.2g; mix well and set aside.

[0031] ③Take 300g of simethicone oil with a viscosity of 100mPa·s, slowly pour 100g of calcium chloride solution with a mass fraction of 10% into the simethicone oil. After the oil-water layer was separated, the oil phase was heated to 70°C, and the reaction liquid was added dropwise. After the reaction, the filter bucket was lifted to collect...

Embodiment 2

[0033] Preparation method of core-shell water-locking material:

[0034] ① Add 72.06g of acrylic acid to 38.88g of deionized water, mix well, and neutralize with 30% sodium hydroxide solution (26g of sodium hydroxide + 60.67g of deionized water) at room temperature until the neutralization degree is 65%. Then 24.02 g of acrylamide was added.

[0035] ② After the neutralization solution is cooled to room temperature, add sodium alginate: 2g, tetraallyloxyethane: 0.48g, azobisisobumisole hydrochloride: 0.2g, ammonium persulfate: 0.05g, carbonic acid Sodium hydrogen: 1.6g, urea: 4.8g, ethanol: 3.2g; mix well and set aside.

[0036] ③Take 300g of simethicone oil with a viscosity of 100mPa·s, slowly pour 100g of calcium chloride solution with a mass fraction of 10% into the simethicone oil. After the oil-water layer was separated, the oil phase was heated to 70°C, and the reaction liquid was added dropwise. After the reaction, the filter bucket was lifted to collect the product,...

Embodiment 3

[0038] Preparation method of core-shell water-locking material:

[0039] ① Add 72.06g of acrylic acid to 38.88g of deionized water, mix well, and neutralize with 30% sodium hydroxide solution (26g of sodium hydroxide + 60.67g of deionized water) at room temperature until the neutralization degree is 65%. Then 24.02 g of acrylamide was added.

[0040]② After the neutralization solution is cooled to room temperature, add sodium alginate: 2g, tetraallyloxyethane: 0.48g, azobisisobumizole hydrochloride: 0.2g, potassium persulfate: 0.05g, carbonic acid Potassium hydrogen: 1.6g, urea: 4.8g, acetone: 3.2g; mix well and set aside.

[0041] ③Take 300g of simethicone oil with a viscosity of 100mPa·s, slowly pour 100g of calcium chloride solution with a mass fraction of 10% into the simethicone oil. After the oil-water layer was separated, the oil phase was heated to 70°C, and the reaction liquid was added dropwise. After the reaction, the filter bucket was lifted to collect the produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com