Multistage suspension melting crystallization method for separating p-xylene

A suspension melting crystallization, p-xylene technology, applied in crystallization purification/separation, organic chemistry and other directions, can solve the problems of unstable operation of aging kettles and high production energy consumption, achieve the elimination of fine crystal recovery steps, reduce energy consumption, and ensure Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

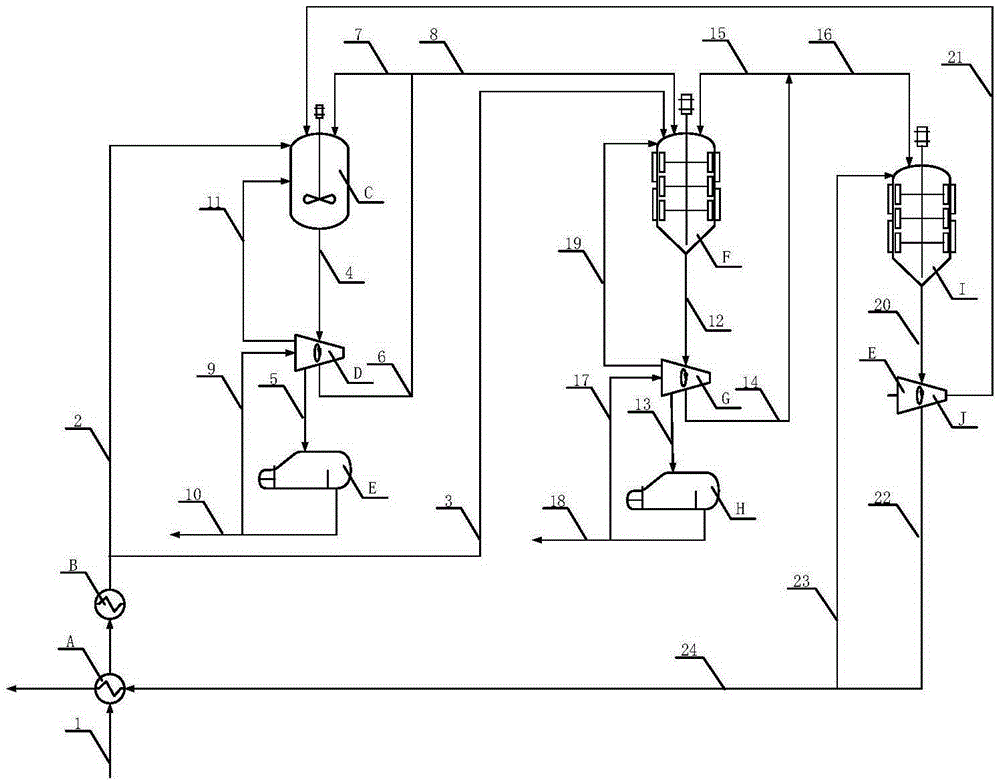

[0026] The invention relates to a multistage suspension melting crystallization method for separating p-xylene.

[0027] Such as figure 1 Said, containing p-xylene concentration is 95% raw material 1, flow rate is 1075kg / h, after being cooled by mother liquor heat exchanger A and precooler B, be divided into two strands, a part of raw material 2 enters aging kettle C to pair two Toluene crystals 21 are subjected to beating, washing and heating aging at an operating temperature of 8°C. A part of the raw material 3 enters the primary crystallizer F for crystallization at a crystallization temperature of 3°C; the residence time of the crystal slurry 4 in the aging kettle C is 30 minutes, containing 30% p-xylene crystals, separated by solid-liquid separator D to obtain p-xylene crystals 5 and aging mother liquor 6, the aging mother liquor 6 is divided into two shares, and the first share of 60% by weight of the aging mother liquor 7 returns in the aging kettle C , the aging mothe...

Embodiment 2

[0029] The invention relates to a multistage suspension melting crystallization method for separating p-xylene. According to the operating conditions of Example 1, wherein the flow rate of raw material 3 entering the primary crystallizer is 430kg / h, the results are listed in Table 1.

Embodiment 3

[0031] The invention relates to a multistage suspension melting crystallization method for separating p-xylene. According to the operating conditions of Example 1, wherein the flow rate of raw material 3 into the primary crystallizer is 645kg / h, the results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com