Recycled backfill concrete prepared from domestic waste incineration residue and its application

A domestic waste incineration and concrete technology, which is applied in the field of recycled backfill concrete, can solve the problems of low utilization rate of solid waste and reduced compressive strength of recycled backfill concrete, and achieve high utilization rate of solid waste, high compressive strength, and saving land resources Effect

Active Publication Date: 2019-05-28

SHENZHEN GRANDLAND DECORATION GROUP

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0015] In order to solve the problems that the compressive strength of recycled backfill concrete is reduced and the utilization rate of solid waste is low when the solid waste content is high, the invention provides a recycled backfill concrete prepared from domestic waste incineration residues and its application

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0045]

Embodiment 2

[0047]

Embodiment 3

[0049]

[0050]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

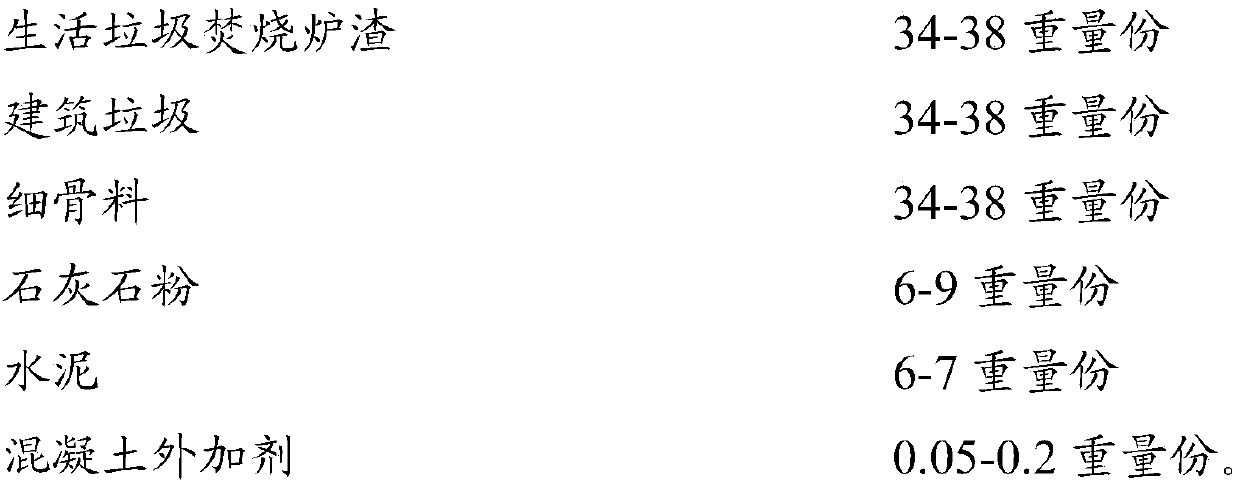

The invention discloses regenerated backfill concrete prepared from domestic garbage incineration residues and application of the regenerated backfill concrete and belongs to the field of preparation of the regenerated backfill concrete. The regenerated backfill concrete is prepared from the following components in parts by weight: 30 to 40 parts of the domestic garbage incineration residue, 30 to 40 parts of construction waste, 30 to 40 parts of fine aggregate, 5 to 10 parts of limestone powder, 5 to 10 parts of cement and 0.03 to 1 part of a concrete additive. The optimal grading is realized by utilizing substances with different grain diameters; in a preparation process, the substances with relatively small grain diameters are filled into gaps among the substances with last-grade grain diameters in a mixing process through selection of specific grain diameters of all components, so that the adhesion between all grades of the grain diameters is enhanced; the gaps in the concrete are reduced and the compressive strength and durability of the concrete are greatly improved. To sum up, the regenerated backfill concrete with high solid waste content is successfully prepared and has the advantages of high solid waste utilization rate, high compressive strength and the like; meanwhile, the occupied area of solid wastes is also reduced and land resources are saved.

Description

technical field [0001] The invention relates to the field of preparation of recycled backfill concrete, in particular to a recycled backfill concrete prepared by using domestic waste incineration residues and its application. Background technique [0002] With the acceleration of urbanization, the production of municipal solid waste has increased significantly. According to statistics, as of 2010, the annual output of urban domestic waste in my country has reached 352 million tons, and the garbage dump stock has reached more than 7 billion tons. 2 / 3 of the cities in the country are surrounded by garbage. The waste incineration technology can reduce the volume of domestic waste by more than 90% and the quality by about 70%. It can also obtain electricity while reducing the volume of waste incineration. Therefore, the incineration method is considered to be an effective method for the treatment of domestic waste. However, waste incineration produces about 30% (mass fraction) ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B28/00C04B28/14

CPCC04B28/00C04B28/144C04B2201/50C04B18/10C04B18/167C04B14/28C04B7/00C04B24/223C04B18/08C04B24/2652C04B2103/302

Inventor 李少强陈国谦

Owner SHENZHEN GRANDLAND DECORATION GROUP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com