Zeolite powder production line and production process

A production line and technology of zeolite powder, applied in the direction of crystalline aluminosilicate zeolite, filter screen, grid, etc., can solve problems such as open flame, low production and processing efficiency, low modification efficiency, etc. The effect of improving quality and quality and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] The present invention will be further described below in conjunction with the accompanying drawings.

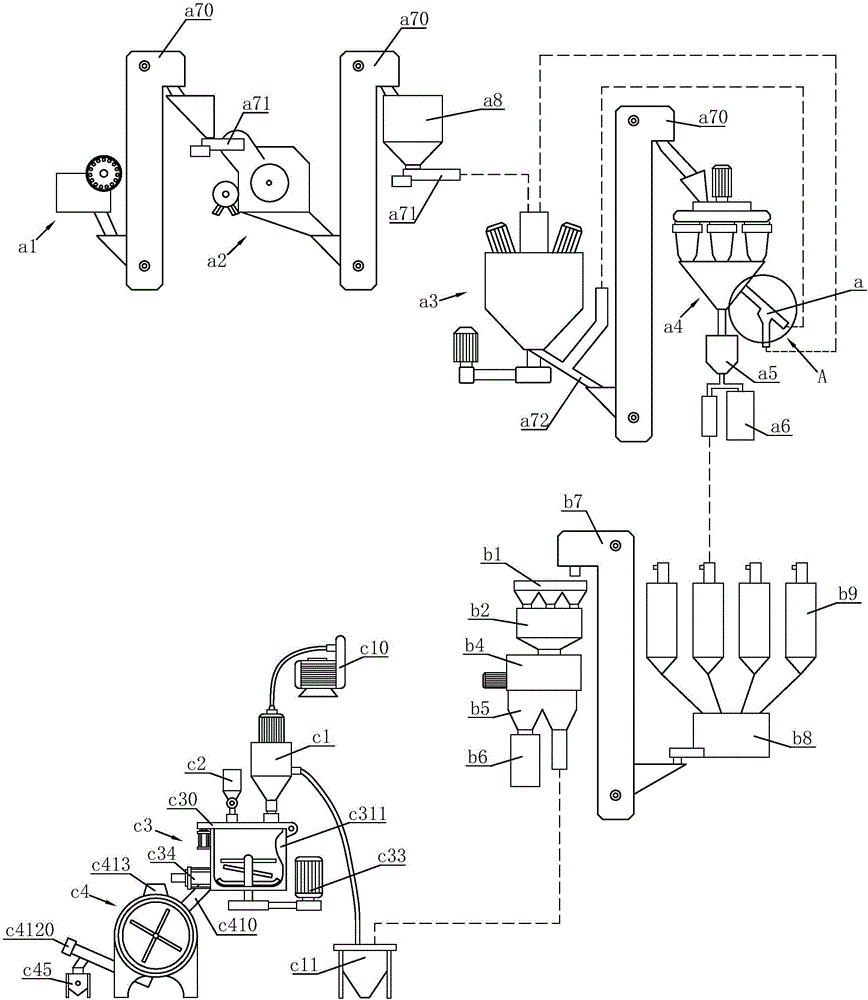

[0097] Such as figure 1 The zeolite powder production line shown includes stone powder crushing system a, powder removal and mixing system b and modified cooling system c.

[0098] Stone powder crushing system a, including coarse crusher a1, fine crusher a2, mill a3, classifier a4, feeding device, feeding mechanism a71, material storage device a8 and material control system, feeding mechanism a71 is connected to mill a3 Material port and storage device a8.

[0099] Among them, the coarse crusher a1 adopts jaw crusher, the fine crusher a2 adopts hammer crusher, the mill a3 adopts generalized mill, the feeding device adopts the combination of bucket elevator a70 and vibrating feeder, and the classifier a4 adopts airflow classification machine.

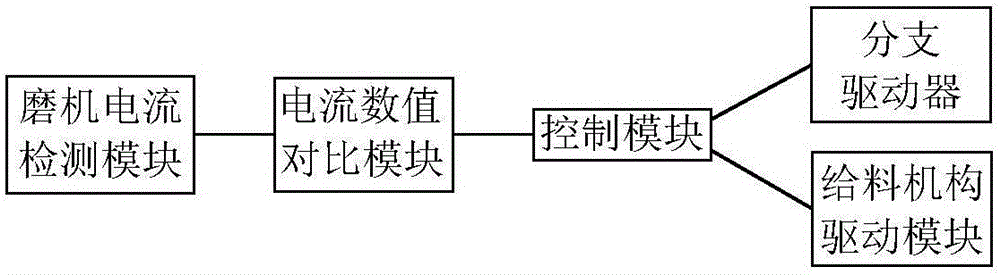

[0100] Such as figure 2 The material control system shown above includes: a drive module, a detection module, a comparison...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com