Electric elevating mechanism

A technology of electric lifting mechanism and opening and closing mechanism, applied in the direction of lifting device, etc., can solve the problems of low operation efficiency, inconvenient operation, affecting the efficiency of shelter lifting, etc., and achieve stable support, improve safety, and improve operation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

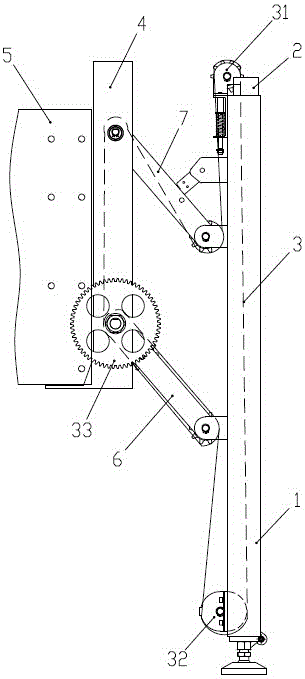

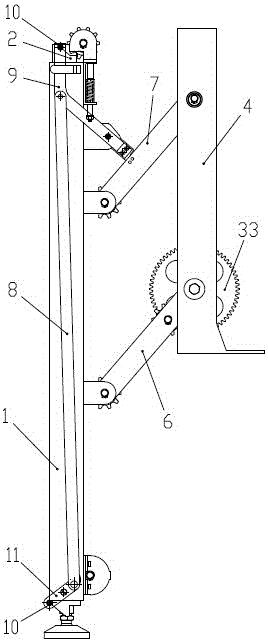

[0040] Such as Figure 1 to Figure 4 As shown, the electric lifting mechanism of this embodiment includes a transmission chain 3 connected to the shelter support 4 and the grounding leg 1, and the transmission chain 3 is driven to rotate by an electric drive device to drive the shelter support 4 and the grounding support. The outrigger inner tube 2 in the outrigger 1 rises and falls synchronously; at least two connecting struts are set between the shelter support 4 and the grounding outrigger 1. In this embodiment, two connecting struts are set, which are respectively the upper The connecting pole 7 and the lower connecting pole 6 are provided with a locking device on the upper connecting pole 7, and a forced opening and closing mechanism is provided corresponding to the locking device, so that when the shelter 5 descends, the locking device automatically locks, and when the shelter 5 When rising, the locking device is automatically unlocked; or as required, when the shelter 5...

Embodiment 2

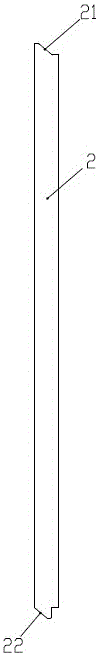

[0052] Such as Figure 1 to Figure 4 As shown, according to the electric lifting mechanism of Embodiment 1, on the basis of Embodiment 1, the upper end and the lower end of the leg inner tube 2 are all set as wedge-shaped surfaces in this embodiment, which are upper wedge-shaped surface 21 and lower wedge-shaped surface 22 respectively.

[0053] Further, such as figure 2 As shown, the lower end of the telescopic rod 8 is connected with a hinge plate 11, one end of the hinge plate 11 is hinged with the end of the telescopic rod 8, and the other end is connected with a roller device 10, and the middle part of the hinge plate 11 is hinged with the ground leg. The roller device 10 is arranged corresponding to the lower wedge-shaped surface 22 . So that when the shelter is lowered, that is, when the leg inner tube 2 is lowered, the lower wedge-shaped surface 21 contacts the roller device at the end of the hinge plate, so that the end of the hinge plate with the roller device rota...

Embodiment 3

[0055] Such as Figure 5 to Figure 7 As shown, according to the electric lifting mechanism described in embodiment 1 or embodiment 2, the electric lifting mechanism also includes a tilting mechanism arranged on the shelter 5, one end of the tilting mechanism is hinged on the shelter 5, and the other end is connected to the shelter 5. The shelter supports 4 are connected, and the tilting mechanism is provided with a driving device that makes its axis tilt, so that the supporting axis of the shelter 5 is inclined outward relative to the vertical direction.

[0056] The shelter tilting mechanism set on the electric lifting mechanism, after the shelter rises to a certain position, the support axis of the shelter is tilted outward relative to the vertical direction through the tilting mechanism, the support is stable, and the shelter is not easy to overturn. Then, the direction of the supporting axis of the shelter is offset from the vertical direction, and the shaft supporting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com