Automatic conveying and truck loading system for cement

An automatic conveying and cement technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of increasing factory costs, waste of human resources, and low loading efficiency, so as to improve loading efficiency, meet customer needs, and reduce manpower Resource Cost Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

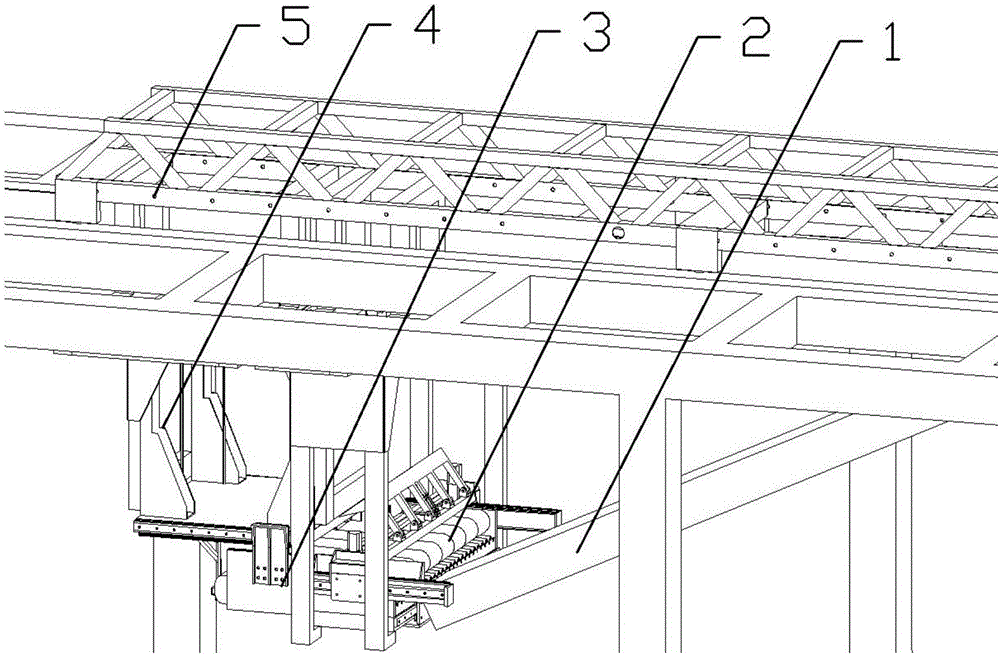

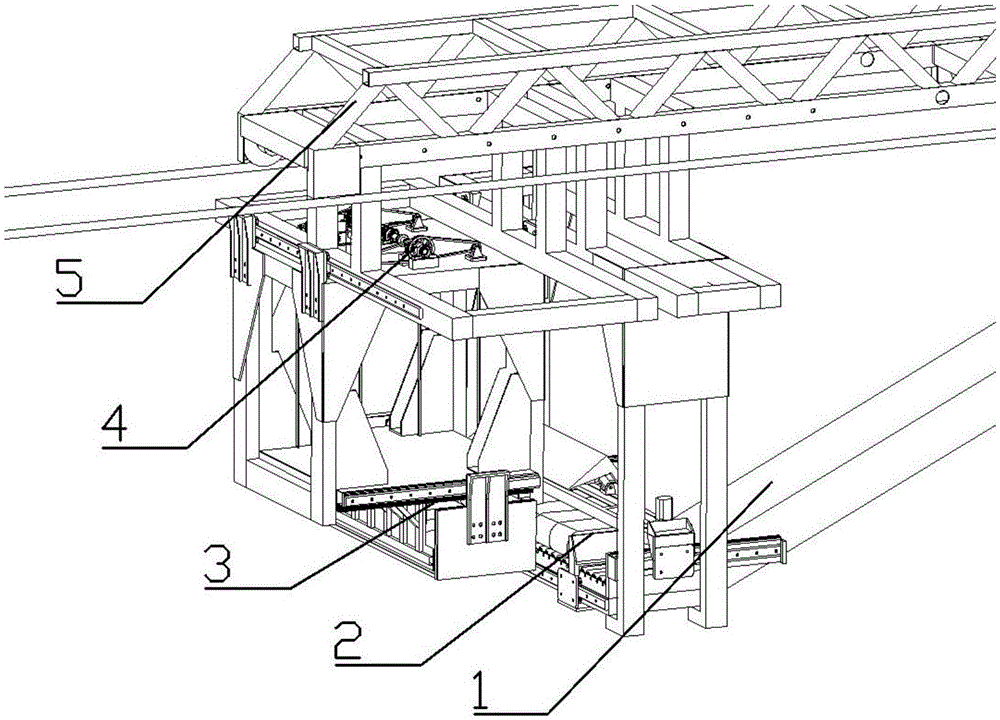

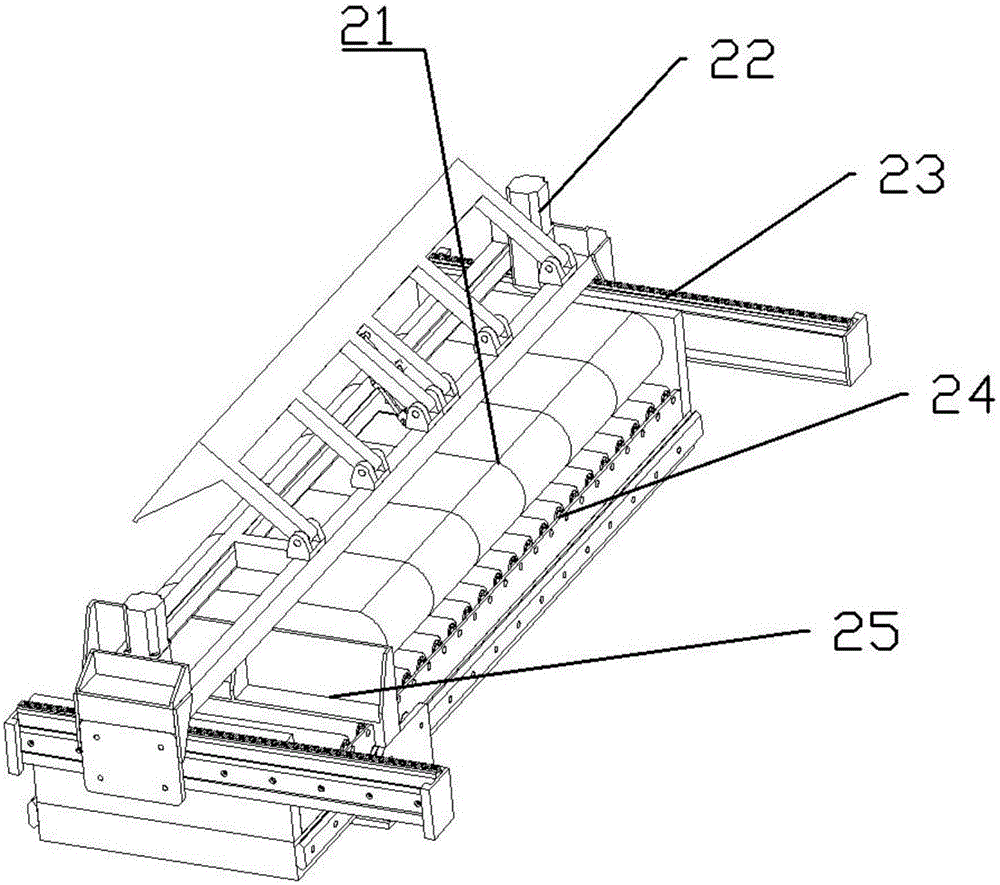

[0035] Such as figure 1 with figure 2 As shown, a cement automatic conveying and loading system includes a cement conveyor belt 1, a bag pushing device 2, a bag unloading device 3, a lifting device 4, and a loading alignment device 5; the loading alignment device 5 is fixed on a factory building elevated Above, the bag pushing device 2 and the lifting device 4 are connected to the loading alignment device 5; the input end of the bag pushing device 2 is set at the output port of the cement conveyor belt 1 for receiving The cement conveyor belt 1 transports the cement bags 21 to be loaded and the cement bags 21 to be accepted are aligned; the unpacking device 3 is arranged directly below the lifting device 4 and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com