Manipulator and machine tool

A manipulator and track technology, applied in the directions of manipulators, metal processing, chucks, etc., can solve the problems of center position deviation and low grasping accuracy of the workpiece to be processed, and achieve the effect of precise clamping and alleviating the low grasping accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

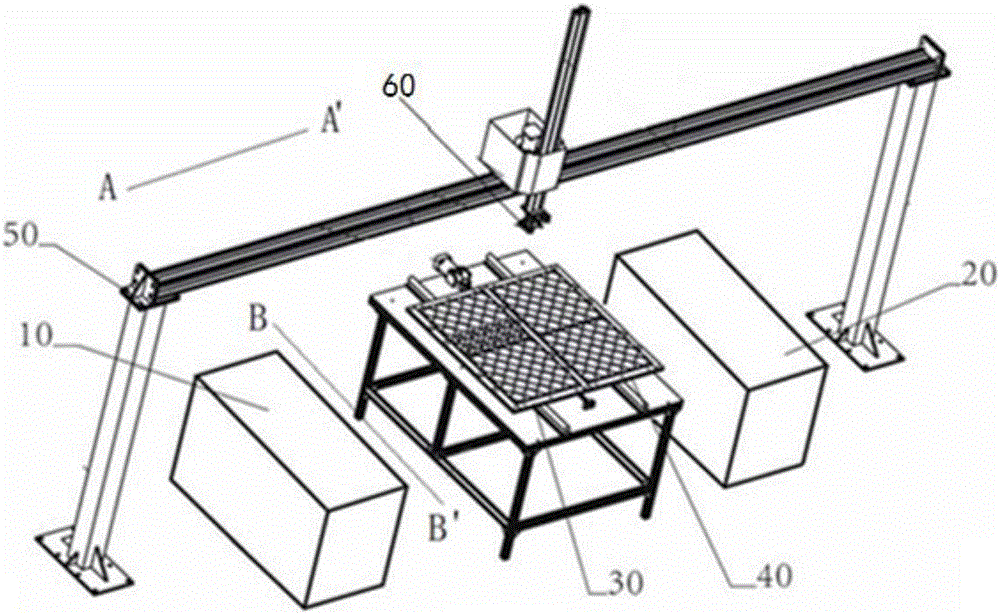

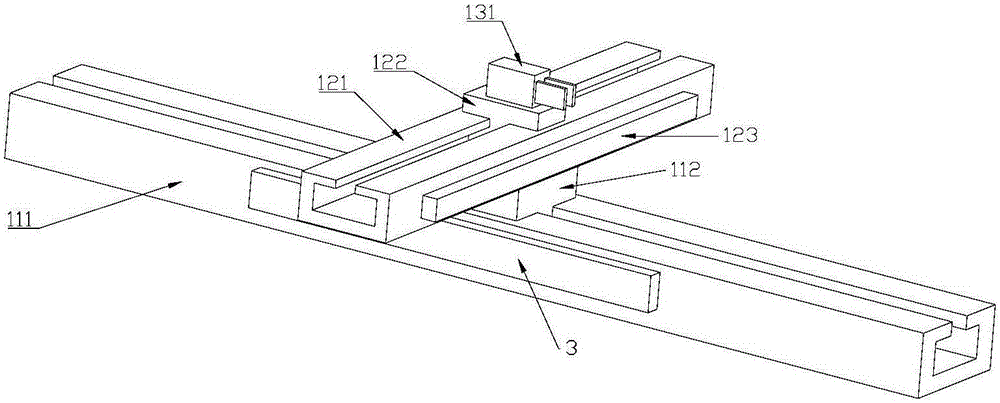

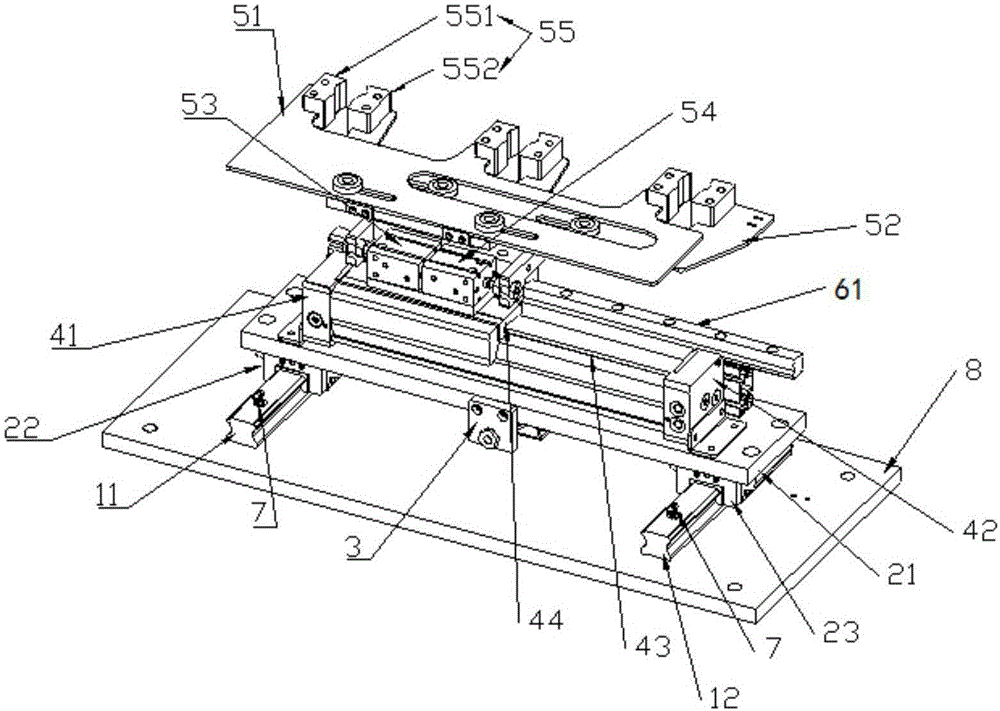

[0033] A kind of manipulator provided by the embodiment of the present invention, such as figure 2As shown, it includes: a longitudinal moving assembly, a lateral moving assembly and a clamping assembly 131, wherein,

[0034] The longitudinal movement assembly includes a first rail 111, a first slider 112 and a first driving part 3, and the first driving part 3 is used to drive the first slider 112 to move longitudinally along the first rail 111 in the horizontal direction;

[0035] The lateral movement assembly includes a second rail 121, a second slider 122 and a second driving part 123, and the second driving part 123 is used to drive the second slider 122 to move laterally along the second rail 121 in the horizontal direction;

[0036] The first slider 112 is fixedly connected to the second track 121 , and the second slider 122 is fixedly connected to the clamping assembly 131 , and the lateral movement and the longitudinal movement are movements in directions perpendicul...

Embodiment 2

[0062] A machine tool provided by an embodiment of the present invention includes: a workpiece processing component, a controller and Figure 2 to Figure 4 For any manipulator provided in the first shown embodiment, the controller is respectively connected with the first drive part 3, the second drive part 123, the third drive part 53 and the fourth drive part 54 of the manipulator, and the workpiece processing part is The workpiece to be processed held by the manipulator is processed.

[0063] Specifically, the controller controls the first driving part 3 to drive the sliding of the first slider 112, controls the second driving part 123 to drive the second sliding block 122 to slide, controls the third driving part 53 to drive the upper manipulator 51 to move, and controls the fourth driving part 53 to drive the upper manipulator 51 to move. The component 54 drives the lower manipulator 52 to move.

[0064]In the embodiment of the present invention, the first slider 112 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com