A gear shaft automatic inserting machine

A gear shaft and automatic technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of assembly quality, labor intensity, production capacity, number of workers and operating experience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

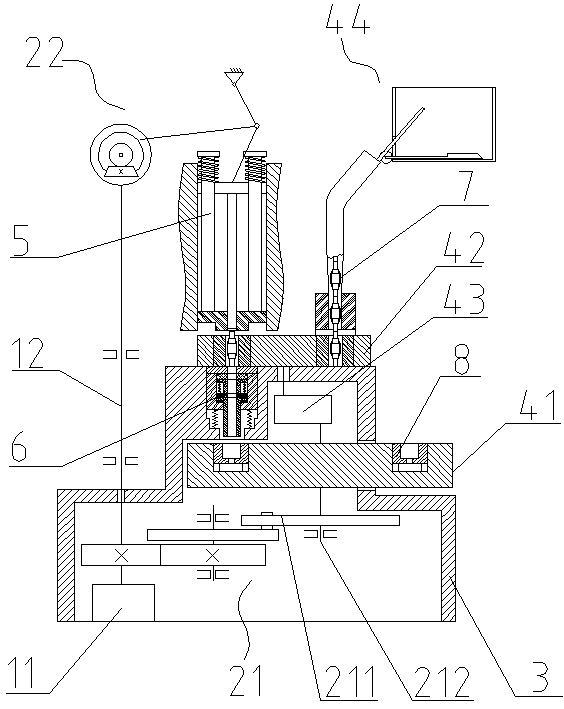

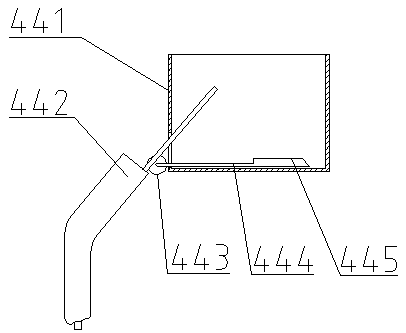

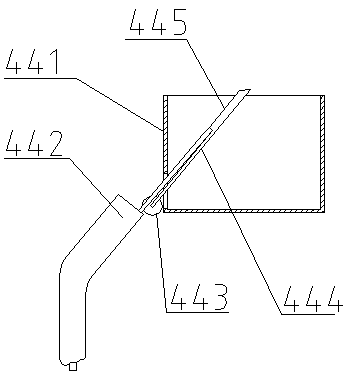

[0028] Such as figure 1As shown, a gear shaft automatic inserting machine at least includes: a frame 3, an inserting mechanism, a feeding mechanism and a transmission mechanism, and the described frame 3 is provided with a driving device 11 and an output shaft 12; The loading mechanism includes an upper inserting device 5, and the upper inserting device 5 includes a push rod 51 that moves up and down along the frame 3; the described feeding mechanism includes a rotating and movable connection with the frame 3; the described first turntable 42 and the second turntable 41 are driven by a gear pair 43, and the diameters of the pitch circles of the two gears that constitute the gear pair 43 are equal; the first turntable 42 and the second turntable 41 rotate at the same time and are still at the same time, and the angular speed of rotation is equal , turn in the opposite direction. The upper mounting grooves 422 are evenly distributed annularly on the first turntable 42, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com