Waste collection device applied to door panel numerical control combined punching

A waste collection and door panel technology, applied in stripping devices, manufacturing tools, pushing equipment, etc., can solve the problems of low waste collection efficiency and high collection labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

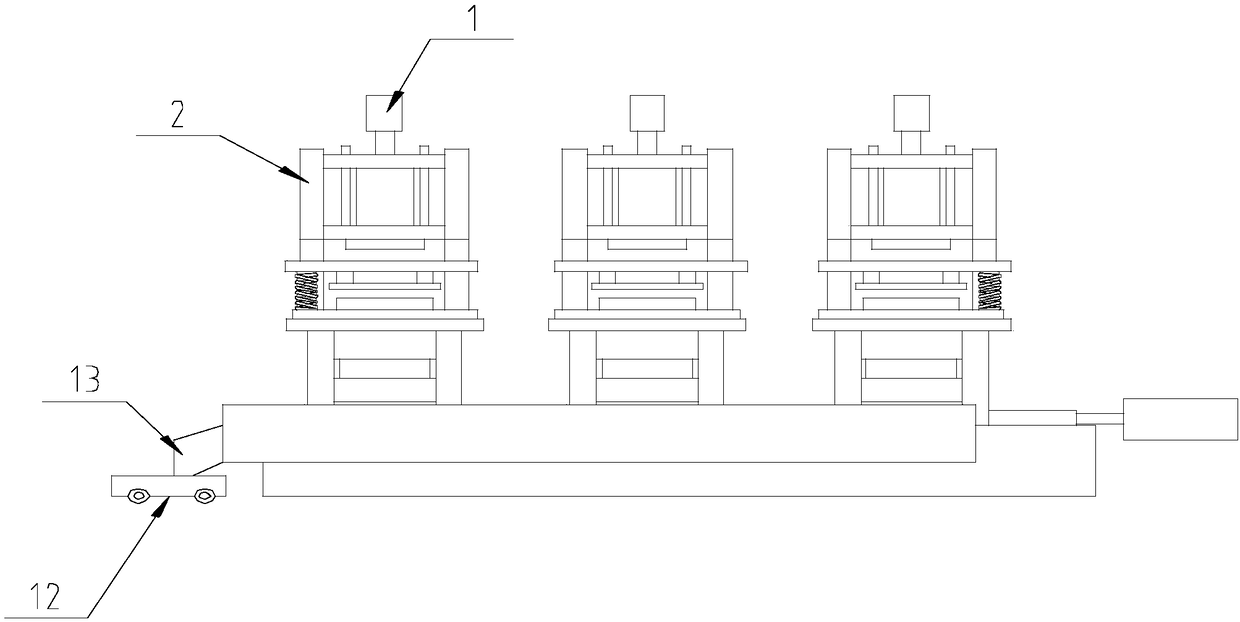

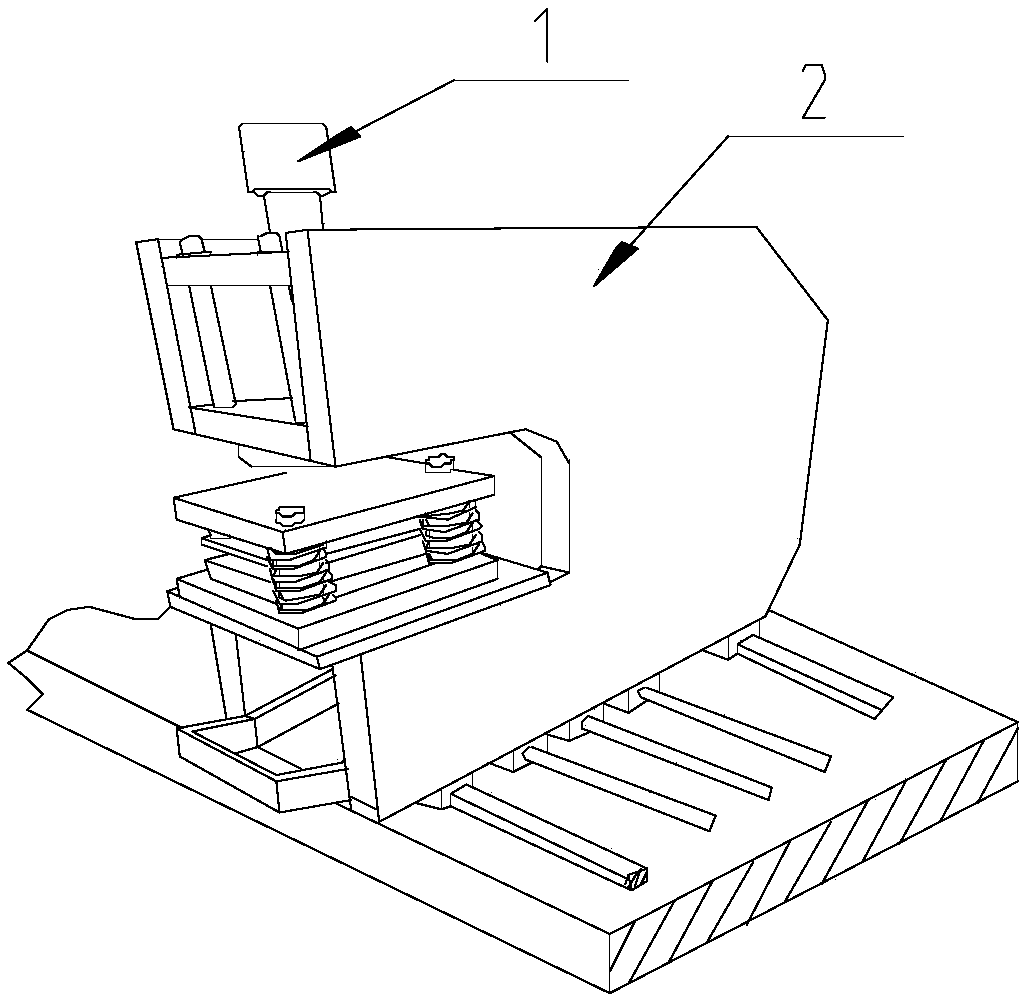

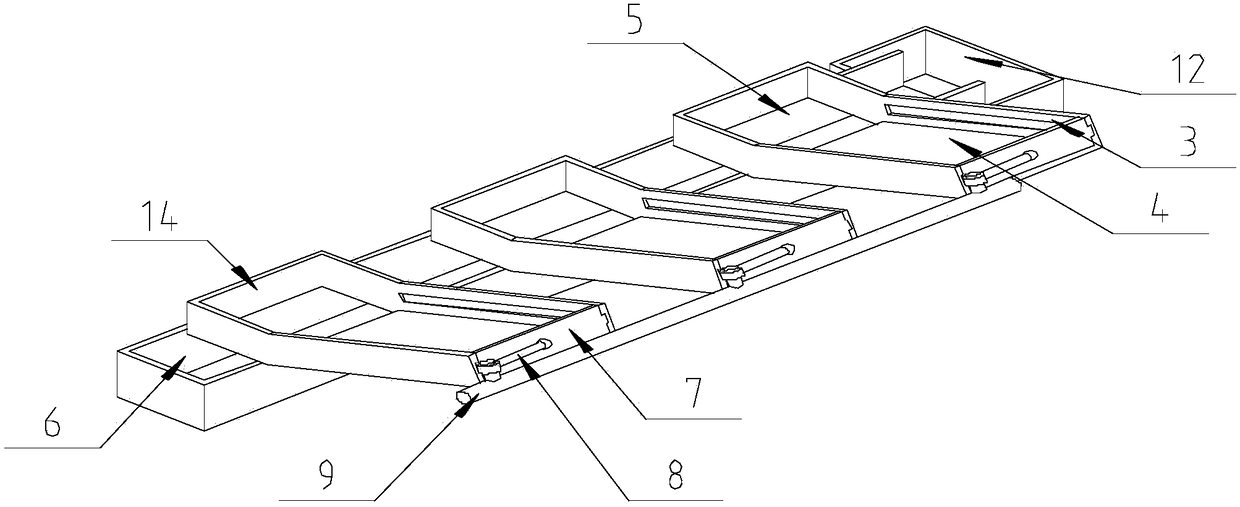

[0026] Such as Figure 1-Figure 6 As shown, the present invention is applied to a waste collection device for door panel numerical control combination punching, including several punching dies 1 and several pairs of support plates 2, and the punching dies 1 are arranged in the middle of a pair of support plates 2, and on the support plates 2 One end close to the ground cooperates with the screw, and connecting plates 3 are arranged on the opposite surfaces of a pair of supporting plates 2. The connecting plates 3 are parallel to the supporting plates 2, and a material holding plate 4 is vertically arranged between the connecting plates 3. , the material holding plate 4 is used to hold the waste produced when the punching die 1 is punched, the connecting plate 3 and the material holding plate 4 are all located below the waste material of the punching die 1, and the connecting plate 3 and the material holding plate On the board 4, one end close to the upper door panel protrudes ...

Embodiment 2

[0033] This embodiment is based on Embodiment 1 to further illustrate the present invention.

[0034]The push rod 9 is still supported by a traditional bearing seat. At the same time, a positioning plate and a spring are arranged on the end of the push rod 9 away from the driving device. The positioning plate is vertically fixed on the ground, and one end of the spring is connected with the end face of the push rod 9. The other end of spring 9 is connected with the side wall of positioning plate. When push pedal 7 was positioned at an end away from the upper door panel, the spring was in a normal state, and when push pedal 7 pushed waste materials into the leakage hole 5, the spring was in a compressed state. When the push plate 7 needs to be returned, the spring in the compressed state generates a thrust to the push rod 9, and the push rod 9 is returned by the thrust, which can reduce the energy consumption of the driving device when returning.

Embodiment 3

[0036] This embodiment is based on Embodiment 1 to further illustrate the present invention.

[0037] One end of the connecting plate 3 close to the upper door panel is provided with a baffle plate 14, the baffle plate 14 is perpendicular to the ground, the material baffle plate 14 can block the waste material pushed over from the material holding plate 4, so that the waste material can only be discharged from the leaking material. Leaked out of hole 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com